Stainless steel security door and manufacturing method thereof

An anti-theft door and stainless steel technology, which is applied in anti-theft, special equipment for doors/windows, windows/doors, etc., can solve problems such as reducing user perception, affecting the appearance of stainless steel anti-theft doors, and easily remaining stains on door panels, so as to save costs The time it takes to control the driving source, improve production efficiency and work efficiency, and eliminate the effect of incomplete cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

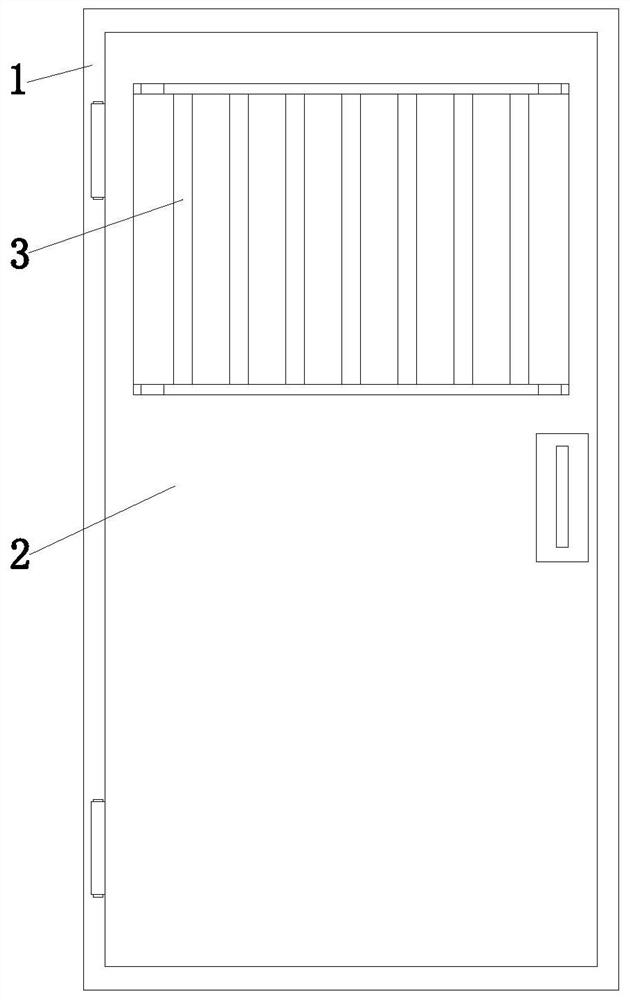

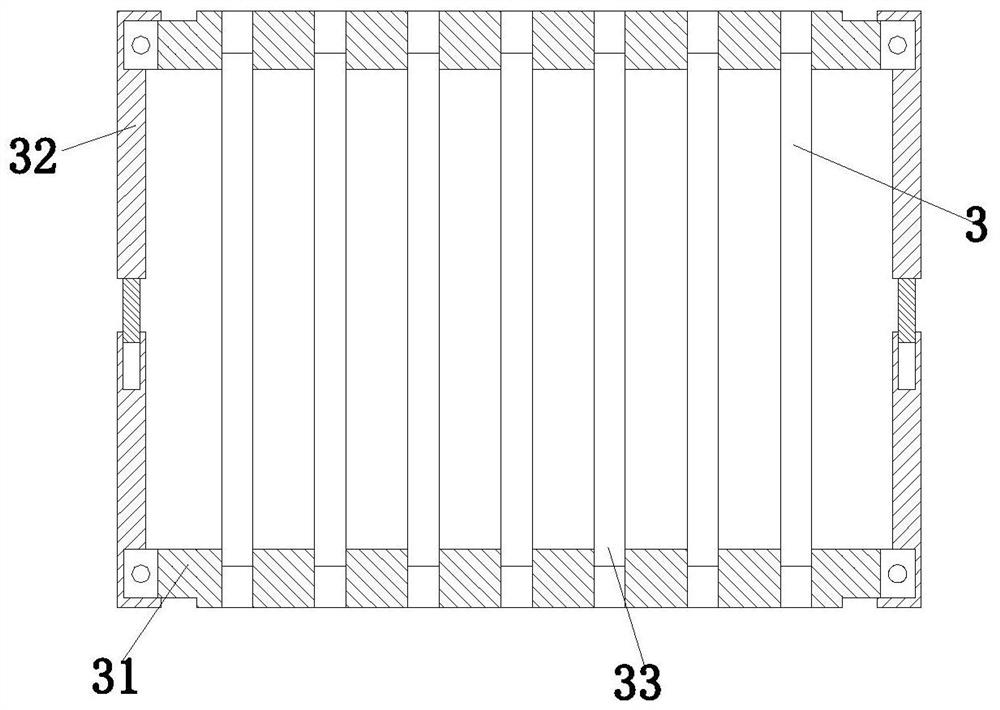

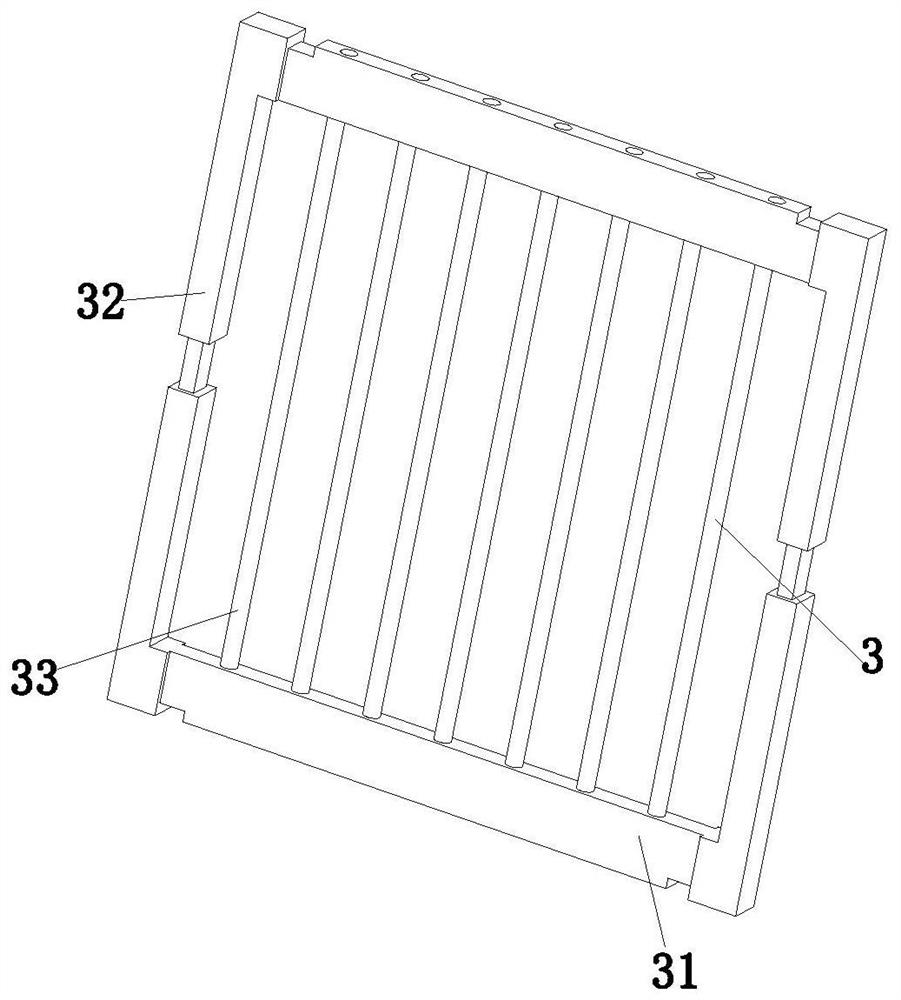

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 The present invention is further described.

[0038] A stainless steel anti-theft door, comprising a door frame 1, a door panel 2 and an anti-theft net 3, one side of the door panel 2 is hinged to the inner side of the door frame 1, the upper and lower sides of the door panel 2 are symmetrically provided with square installation grooves, and the four corners of the rear side of the square installation groove are Threaded holes are provided, and an anti-theft net 3 is installed through bolts in the square installation groove. An anti-theft lock is provided on the side of the door panel 2 that is not hinged with the door frame 1. The anti-theft net 3 includes a connecting horizontal plate 31, a connecting vertical plate 32 and a spacer bar. 33. The number of connecting horizontal plates 31 is two, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com