Efficient intelligent automobile lamp optimization structure

A technology for optimizing structures and automobiles, applied to vehicle components, signal devices, optical signals, etc., can solve problems such as excessively long motor wiring, complex structure, and potential safety hazards, and achieve the effects of improving efficiency, stable transmission, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

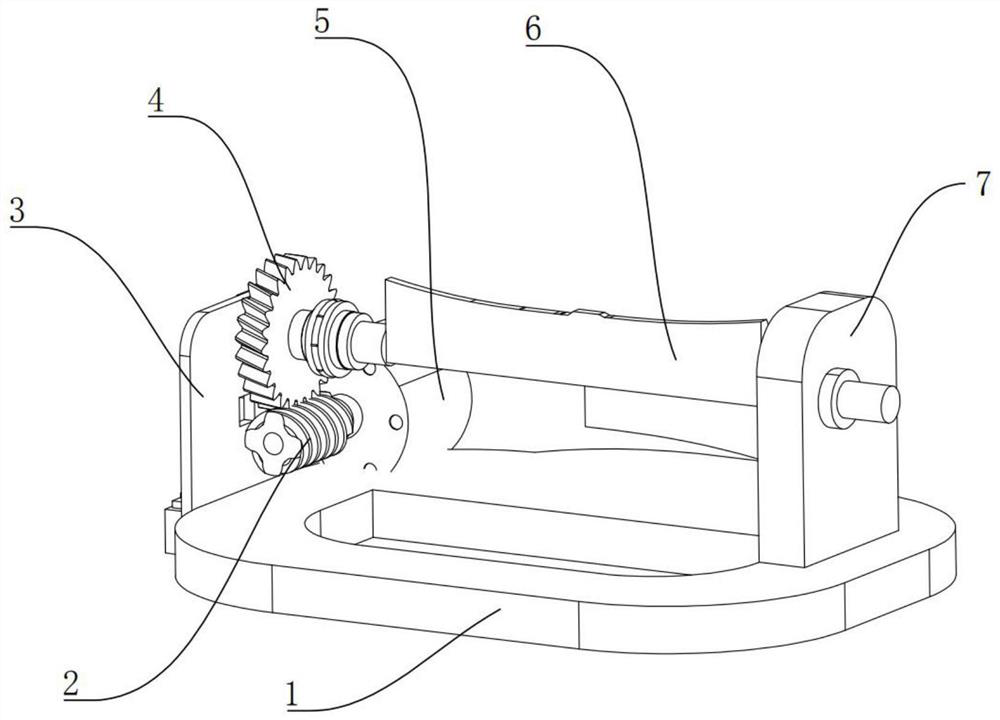

[0017] Shown in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

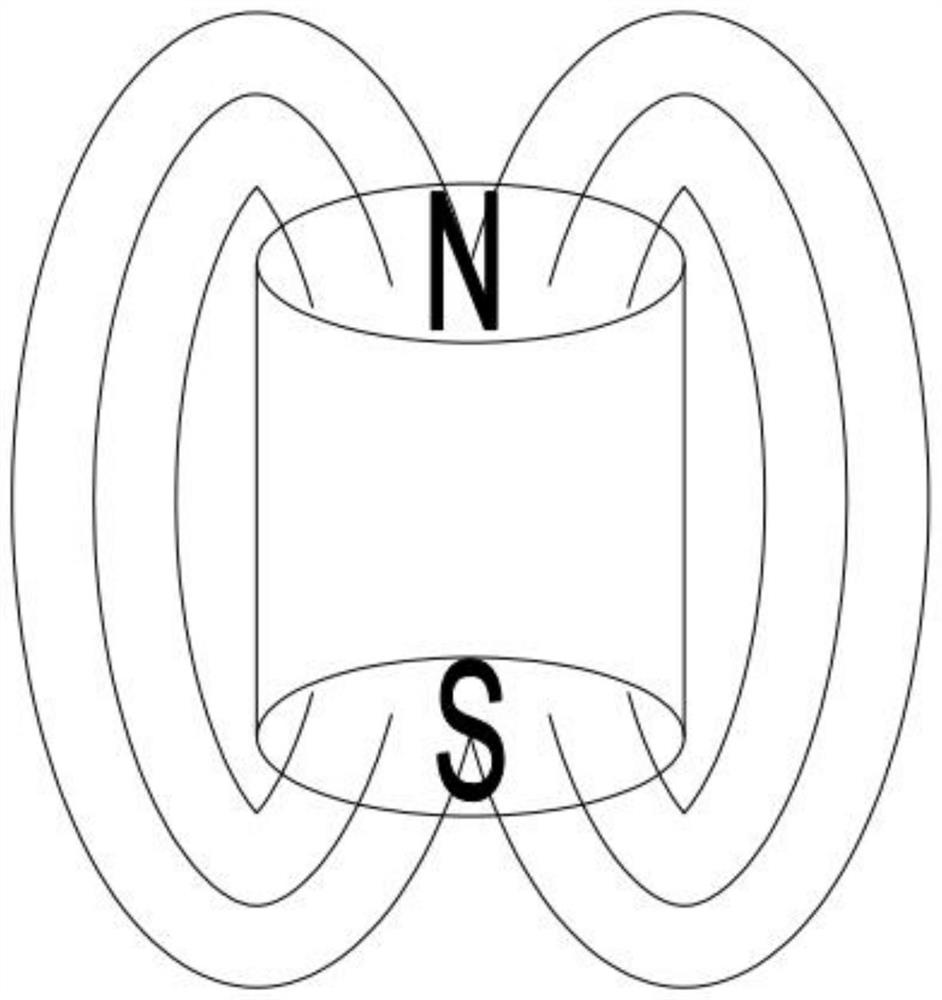

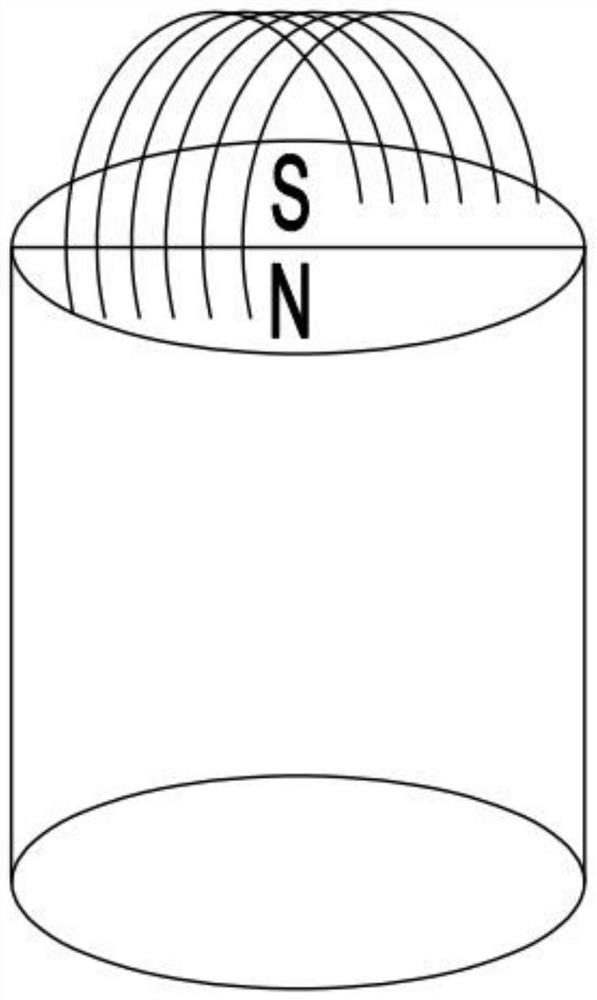

[0018] An optimized structure for high-efficiency automobile intelligent lights, including a base 1, a motor 5, a worm 2, a worm gear 4, and a light shield 6, the worm 2 is connected to the motor 5, the worm gear 4 is engaged with the worm 2, and the base 1 is provided with There are a first bearing seat 3 and a second bearing seat 7, bearings are respectively arranged on the first bearing seat 3 and the second bearing seat 7, the shading plate 6 is arranged on the rotating shaft, and the two ends of the rotating shaft are respectively connected to the first The bearing of the bearing seat 3 and the second bearing seat 7, the worm wheel 4 is arranged on the rotating shaft between the first bearing seat 3 and the light shielding plate 6, and the Hall electromagnetic is placed in the worm wheel 4.

[0019] In this embodiment, preferably, the worm 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com