Quick-release self-locking connecting structure for mounting interior trim part of vehicle cabin

A vehicle and connection structure technology, which is applied in the field of quick-release self-locking connection structure, can solve problems such as not being suitable for the installation of interior parts, and achieve the effect of convenient and fast assembly and disassembly, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

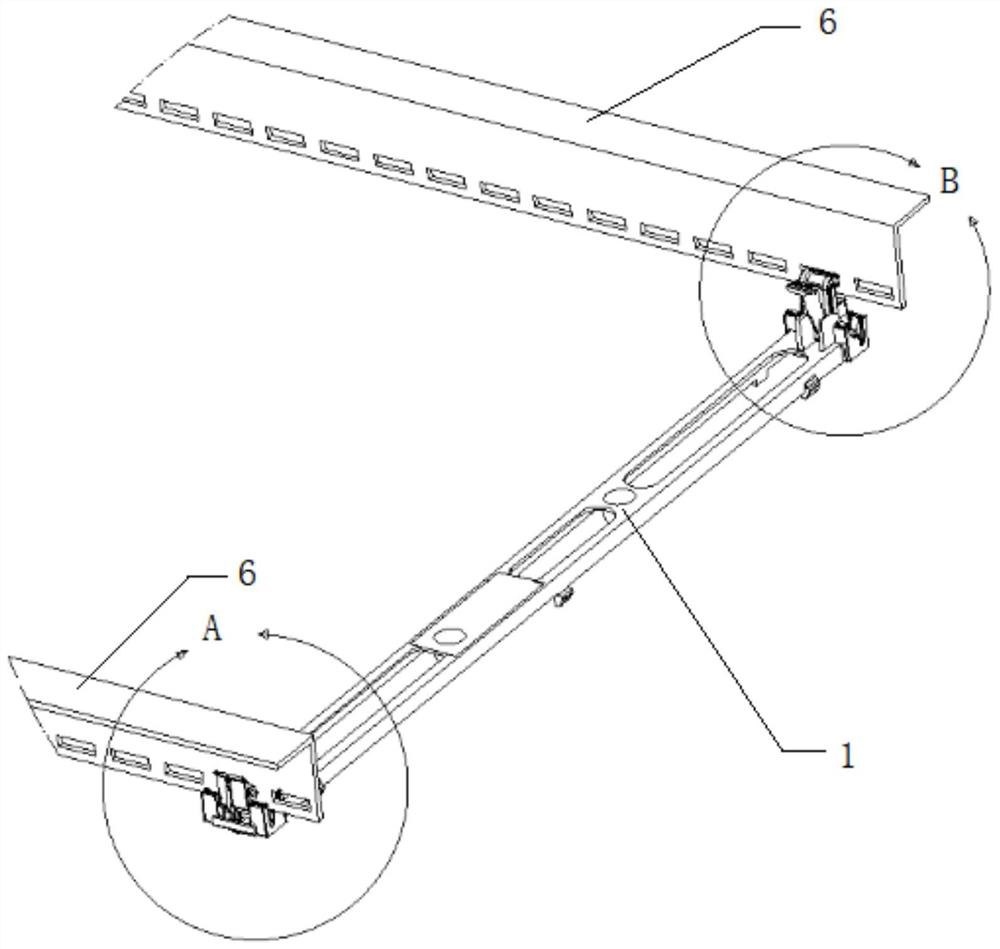

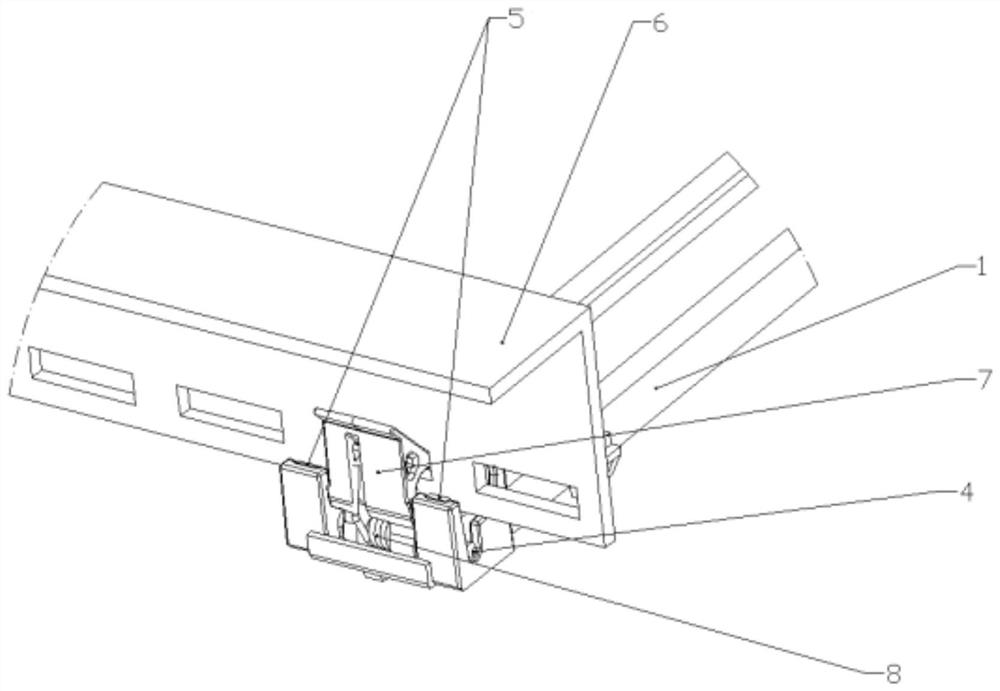

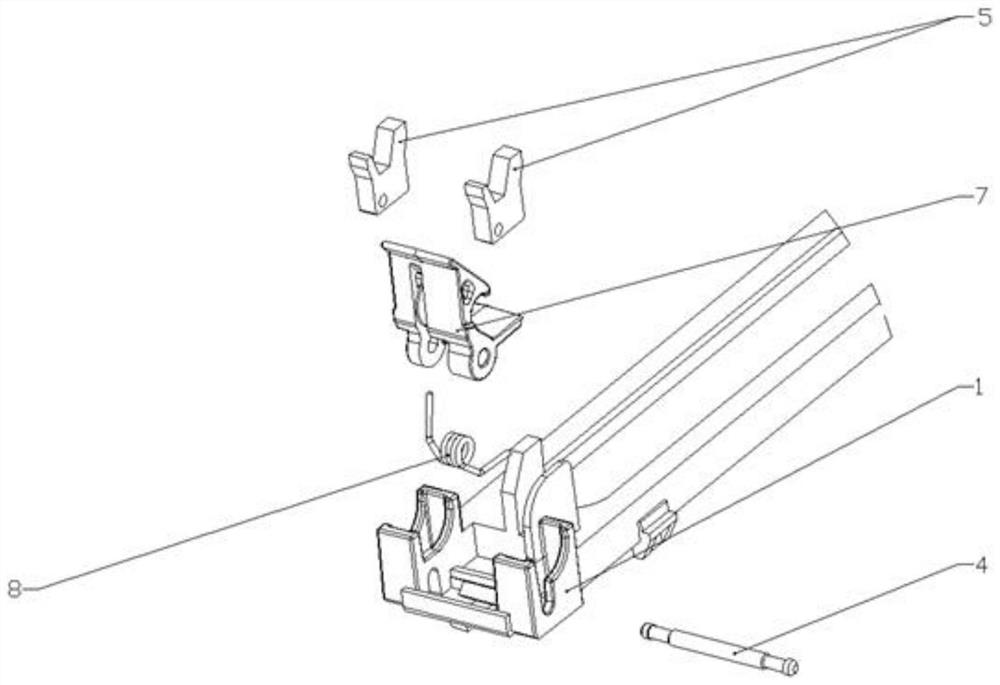

[0031] Such as Figure 1-7 As shown, a quick-release self-locking connection structure for the installation of vehicle cockpit interior parts includes a bracket 1, and the two ends of the bracket 1 are respectively connected with a quick-release hook assembly and a self-locking hook assembly. Both the quick-release hook assembly and the self-locking hook assembly are connected with the installation track 6, and the two form a hook group. Each of the two ends of the bracket 1 has a hook installation groove, one end is used for installing the quick-release hook, and the other end is used for Install the self-locking hook 2. On both sides of the hook installation groove are shaft lock piece installation grooves, three installation grooves are arranged in series, and a through hole runs through the side wall direction.

[0032] The quick-release hook assembly includes a bracket 1, a quick-release hook 7, a spring 8, a quick-release hook pin 4, a quick-release hook lock shaft plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap