A kind of preparation method of utilizing γ-ray radiation to modify polyvinyl chloride

A polyvinyl chloride, gamma ray technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of poor mechanical properties of polyvinyl chloride materials, to improve the poor toughness and improve the mechanical properties. performance, the effect of improving elongation at break and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

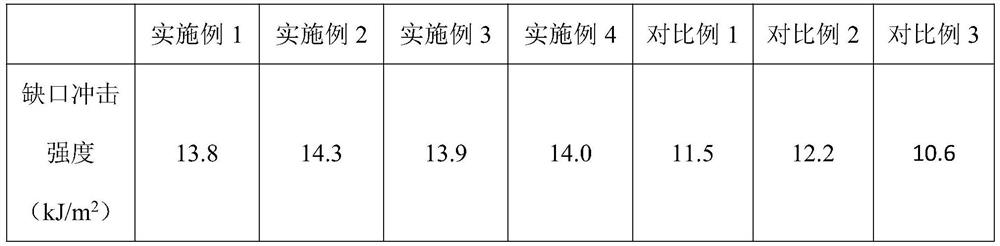

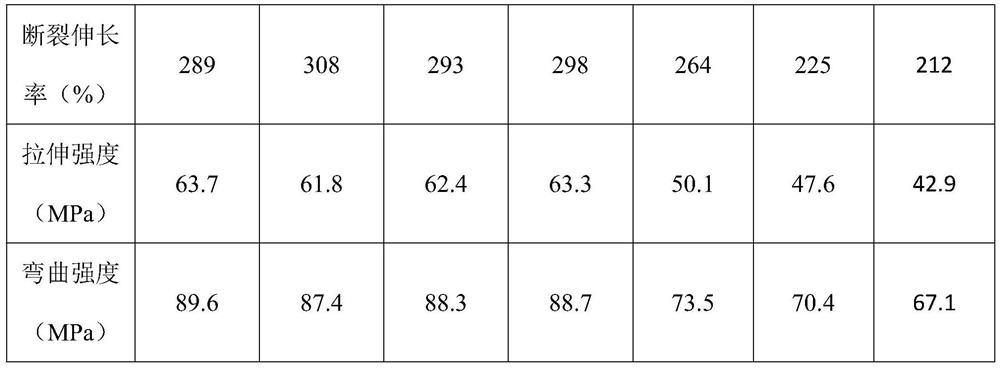

Examples

Embodiment 1

[0027] A preparation method utilizing γ-ray radiation modified polyvinyl chloride, comprising the following preparation steps:

[0028] (1) Disperse 8g of polyvinyl chloride powder uniformly in 100mL of deionized water, add 4g of acrylamide monomer, ultrasonically disperse uniformly, then pass nitrogen into the solution to remove oxygen in the mixed solution, and then send into cobalt 60 irradiation after sealing room irradiation, the irradiation dose is 20kGy, and the irradiation dose rate is 0.5kGy / h. After irradiation, the reaction product is filtered, washed and dried to obtain the polyacrylamide grafted polyvinyl chloride material;

[0029] (2) 10g of hexagonal boron nitride was added to 200mL of 6mol / L sodium hydroxide solution, stirred in an oil bath at 130°C for 6h to carry out a hydroxylation reaction, after the reaction was over, the reaction product was washed and dried, That is to obtain hydroxylated boron nitride;

[0030] (3) Mix 20g of polyacrylamide grafted po...

Embodiment 2

[0032] A preparation method utilizing γ-ray radiation modified polyvinyl chloride, comprising the following preparation steps:

[0033] (1) Uniformly disperse 10g polyvinyl chloride powder in 100mL deionized water, add 5g acrylamide monomer, ultrasonically disperse uniformly, then pass nitrogen into the solution to remove oxygen in the mixed solution, seal and send cobalt 60 to irradiate room irradiation, the irradiation dose is 30kGy, and the irradiation dose rate is 0.6kGy / h. After irradiation, the reaction product is filtered, washed and dried to obtain the polyacrylamide grafted polyvinyl chloride material;

[0034] (2) 15g of hexagonal boron nitride was added to 250mL of 6mol / L sodium hydroxide solution, stirred in an oil bath at 150°C for 6h to carry out a hydroxylation reaction, after the reaction was over, the reaction product was washed and dried, That is to obtain hydroxylated boron nitride;

[0035] (3) Mix 30g of polyacrylamide grafted polyvinyl chloride material ...

Embodiment 3

[0037] A preparation method utilizing γ-ray radiation modified polyvinyl chloride, comprising the following preparation steps:

[0038] (1) Uniformly disperse 12g polyvinyl chloride powder in 100mL deionized water, add 6g acrylamide monomer, ultrasonically disperse uniformly, then pass nitrogen into the solution to remove the oxygen in the mixed solution, and after sealing, send cobalt 60 to irradiate room irradiation, the irradiation dose is 25kGy, and the irradiation dose rate is 1kGy / h. After irradiation, the reaction product is filtered, washed and dried to obtain the polyacrylamide grafted polyvinyl chloride material;

[0039] (2) 12g of hexagonal boron nitride was added to 250mL of 5mol / L sodium hydroxide solution, and stirred in an oil bath at 160°C for 6h to carry out a hydroxylation reaction. After the reaction was completed, the reaction product was washed and dried. That is to obtain hydroxylated boron nitride;

[0040] (3) Mix 35g of polyacrylamide grafted polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com