False twist processing machine

A processing machine, false twisting technology, applied in textile and papermaking, thin material processing, conveying filamentous materials, etc., can solve problems such as broken filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

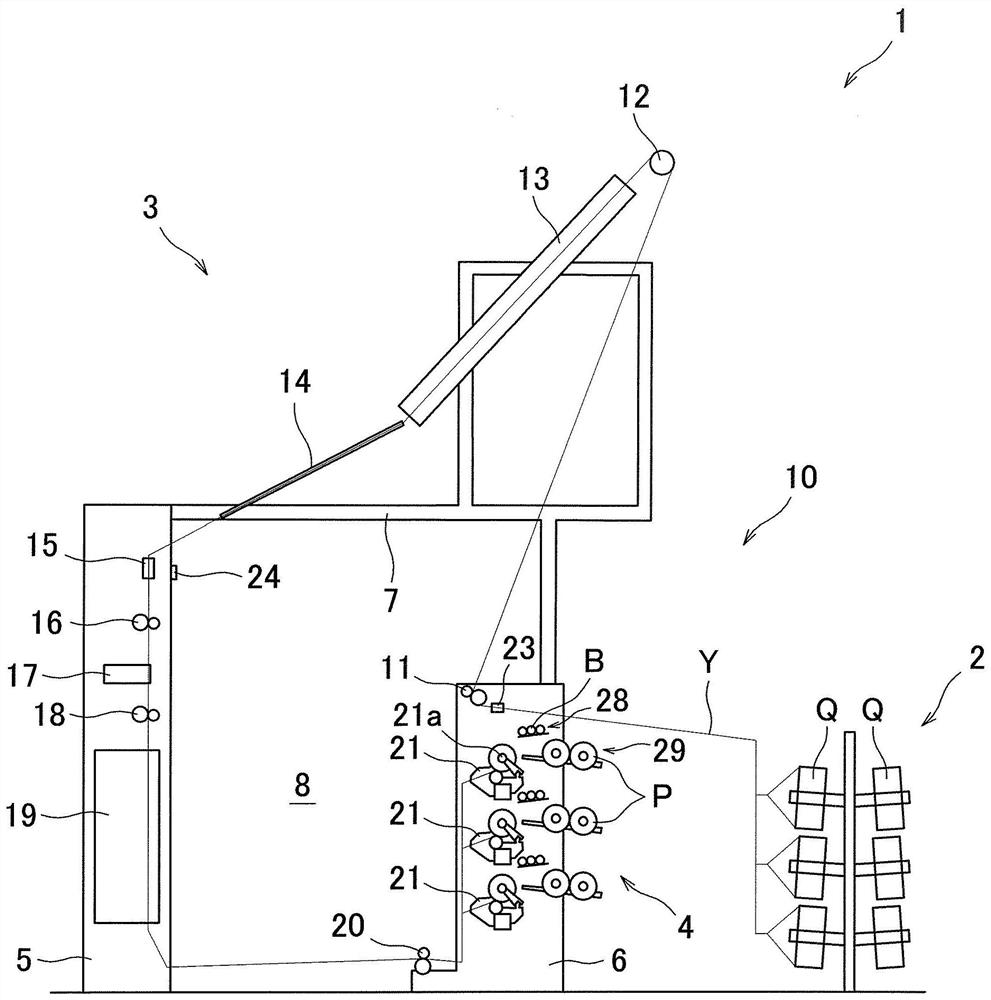

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0028] (Overall structure of false twist processing machine)

[0029] figure 1 It is a schematic diagram which shows the structure of the false twist processing machine 1 of this embodiment. False twist processing machine 1 is constituted as, along figure 1 A plurality of processing units 10 (also referred to as spindles) for performing false-twisting processing on the yarn Y are arranged in a direction perpendicular to the paper surface (hereinafter referred to as the machine length direction). Each processing unit 10 is configured to include a yarn supply unit 2 for supplying the yarn Y, a processing unit 3 for performing false twist processing on the yarn Y supplied from the yarn supply unit 2 , and a yarn Y subjected to false twist processing by the processing unit 3 . The winding portion 4 of the package P is formed by winding up.

[0030] The yarn supply unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com