Method for realizing automatic tunneling of TBM (Tunnel Boring Machine)

An automatic and automatic shutdown technology, which is applied to earthwork drilling, mining equipment, tunnels, etc., can solve problems such as increased consumption of manpower and material resources, high difficulty in equipment operation, and low excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

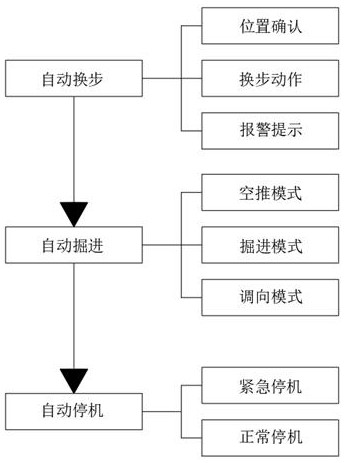

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a method for realizing automatic tunneling of TBM, specifically according to the following operation steps;

[0037] S1: Automatic step change, during the step change process, the way of step change will affect the cutting tool and the speed of excavation;

[0038] S2: automatic excavation, excavating the excavation tunnel;

[0039] S3: Automatic shutdown, providing emergency stop for unexpected accidents, and providing normal stop when workers need to rest;

[0040] S101: confirm the position, confirm the falling position of the support; confirm the next position of the brace; confirm the return position of the bolter and confirm the next position;

[0041] S102: Change steps, tighten the shield cylinder, stretch out the back support and tighten it, retract the shoe cylinder and put it in place, retract the pusher cylinder, put the shoe mechanism in place, extend the shoe and tighten it, retr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com