Bolt with adjustable clamping range

A range and clamping element technology, applied in the field of bolts with adjustable clamping range, can solve the problems of damaged external thread, unable to ensure the compression, etc., to achieve the effect of large adjustment, reliable compression, and improved positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

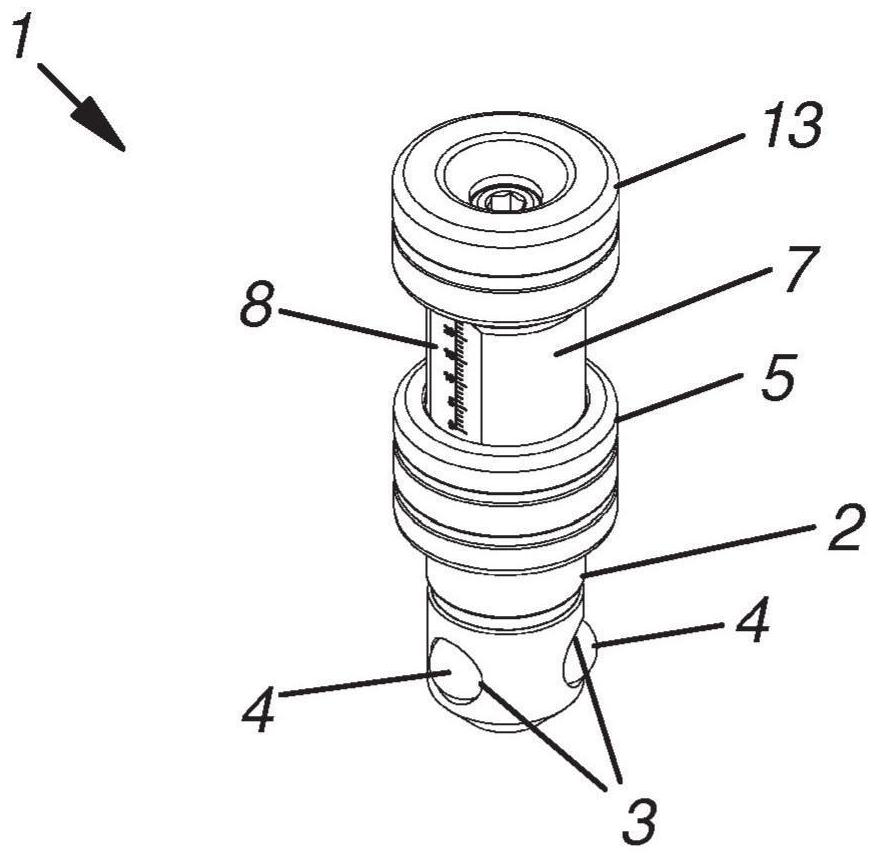

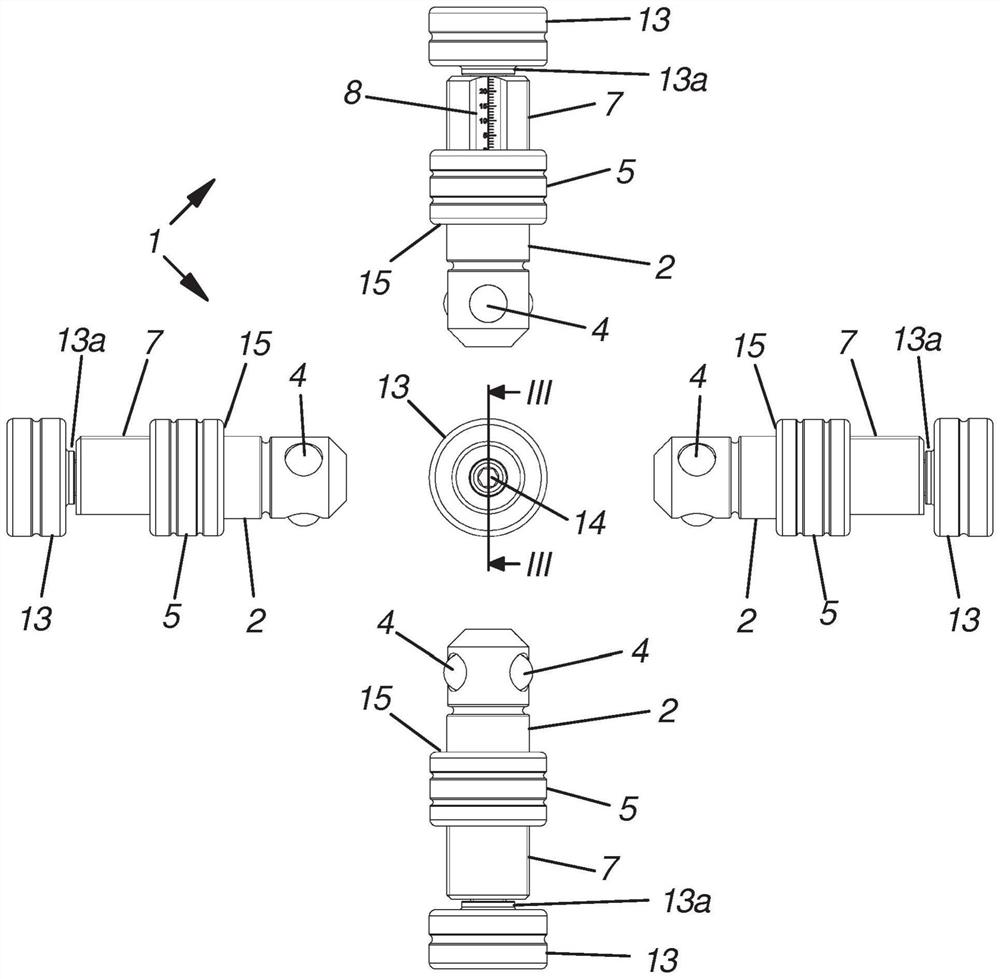

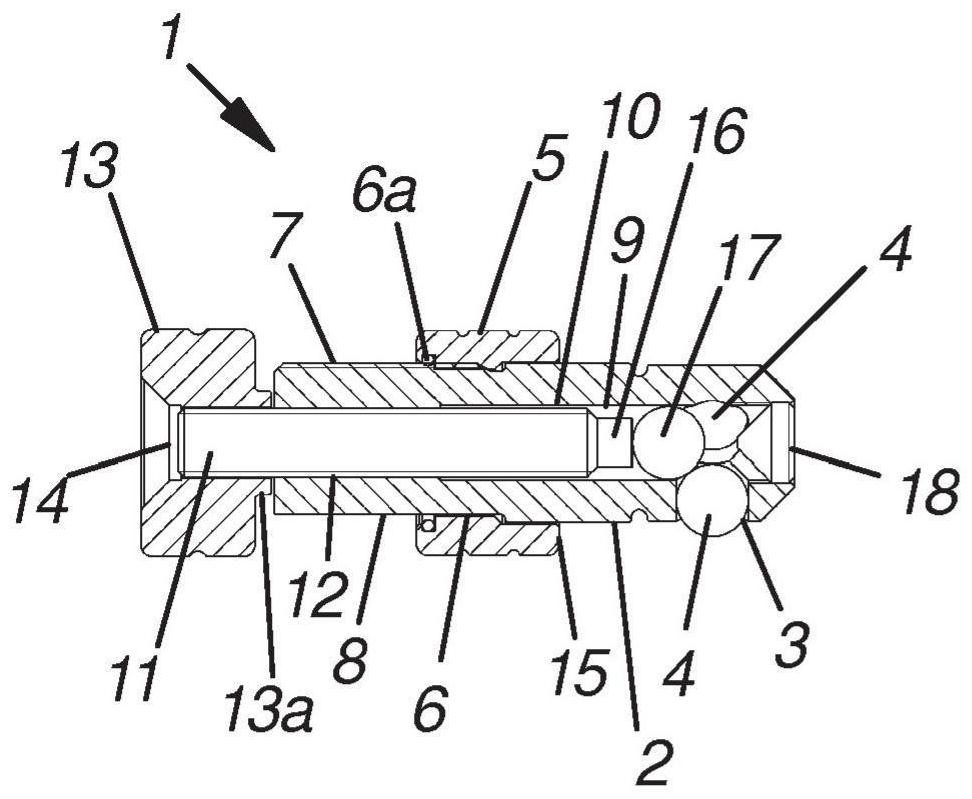

[0028] refer to figure 1 , figure 2 and image 3 A first embodiment of the plug 1 is illustrated. The bolt 1 comprises a bolt-like part 2 which can be introduced into openings of parts which lie on one another. The plug-like part 2 is penetrated by an opening 3 in one end region, and the ball 4 as a clamping element can be positioned at any position due to a bead (not shown) on the outer edge of the opening 3 or other protection such as an O-ring. radially reciprocates within the opening, but cannot completely leave the opening.

[0029] On the other end region of the pin part 2, a threaded sleeve 5 protrudes radially outward from the pin part 2 and is repositionable and fixable in the longitudinal direction of the pin part 2 in that: The threaded sleeve 5 engages with an internal thread 6 to an external thread 7 provided on an outer partial area of the pin part 2 . The threaded sleeve 5 has an inner O-ring 6 a which prevents the adjustability of the threaded sleeve 5 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap