Lever-driven wafer positioning and supporting mechanism

A wafer and lever technology, which is applied to grinding drive devices, surface-polished machine tools, and grinding feed motion, etc., can solve the problems of wafer damage, reduced yield, and overlapping of tool centers that cannot be gripped by wafers. Achieve the effect of stable position, simple structure and constant precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific examples, further illustrate the present invention, the examples are implemented under the premise of the technical solutions of the present invention, it should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

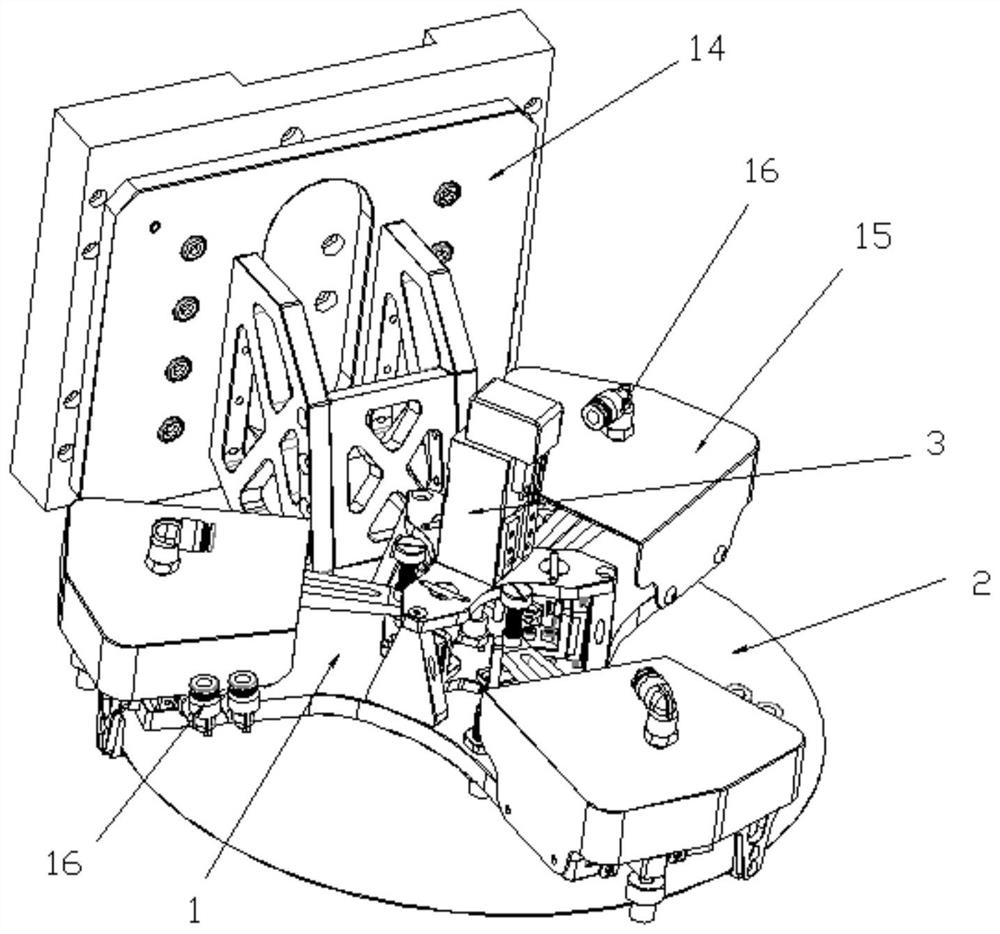

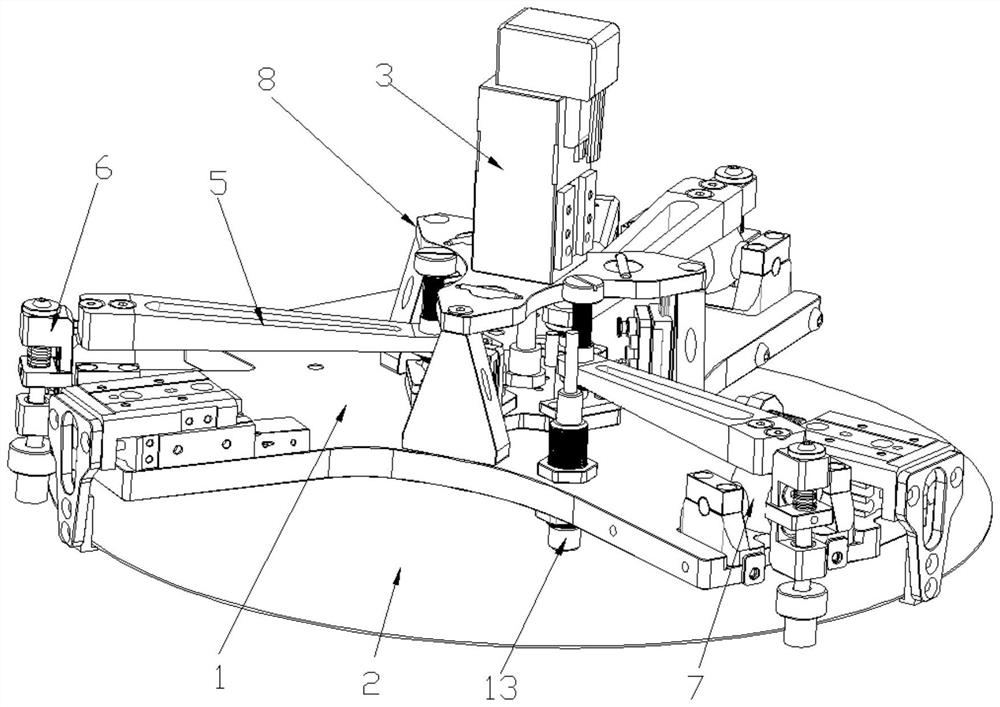

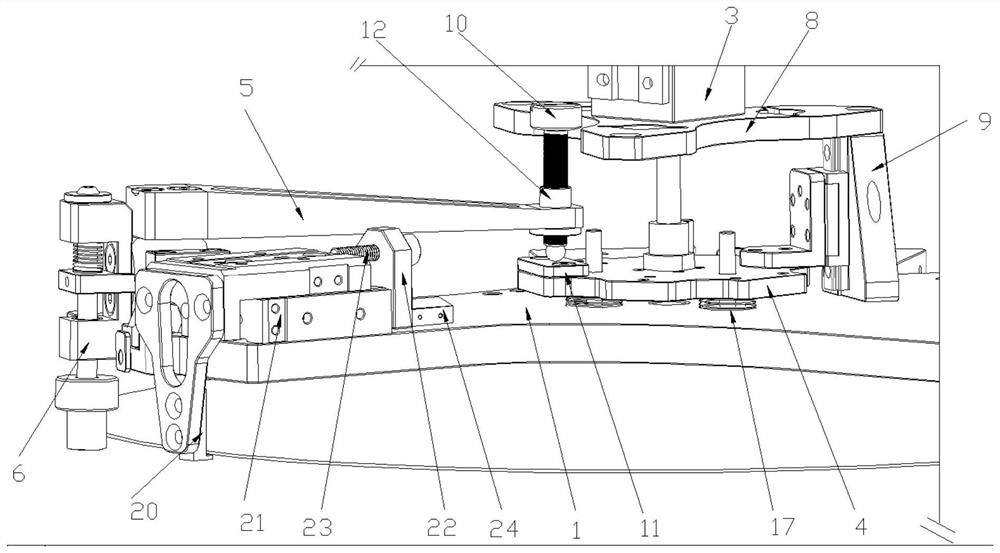

[0029] Such as Figure 1-6 As shown, a lever-driven wafer positioning and lifting mechanism includes a positioning device and a lifting device. Both the positioning device and the lifting device are installed on the bottom plate 1. The positioning device realizes the precise positioning of the wafer 2. Realize that the wafer 2 is picked up and put down.

[0030] The positioning device comprises a driving device 3, a center plate 4, a buffer device, and at least three groups of crowbars 5 and floating positioning fingers 6, and the buffer device is a plurality of springs 17 arranged between the base plate 1 and the center plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com