Modularized supporting unit of steel structure

A support unit and modular technology, applied in construction, bridge construction, bridges, etc., can solve problems such as endangering the life safety of workers, unstable support column fixing, troublesome support column fixation, etc., to achieve convenient disassembly and transfer, and ideal versatility , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The shaped steel is an angle steel.

Embodiment 2

[0039] Embodiment 2: The shaped steel is square steel.

Embodiment 3

[0040] Embodiment 3: The shaped steel is round steel.

[0041] Angle steel is preferred to facilitate fabrication and improve the firmness of tailor welding.

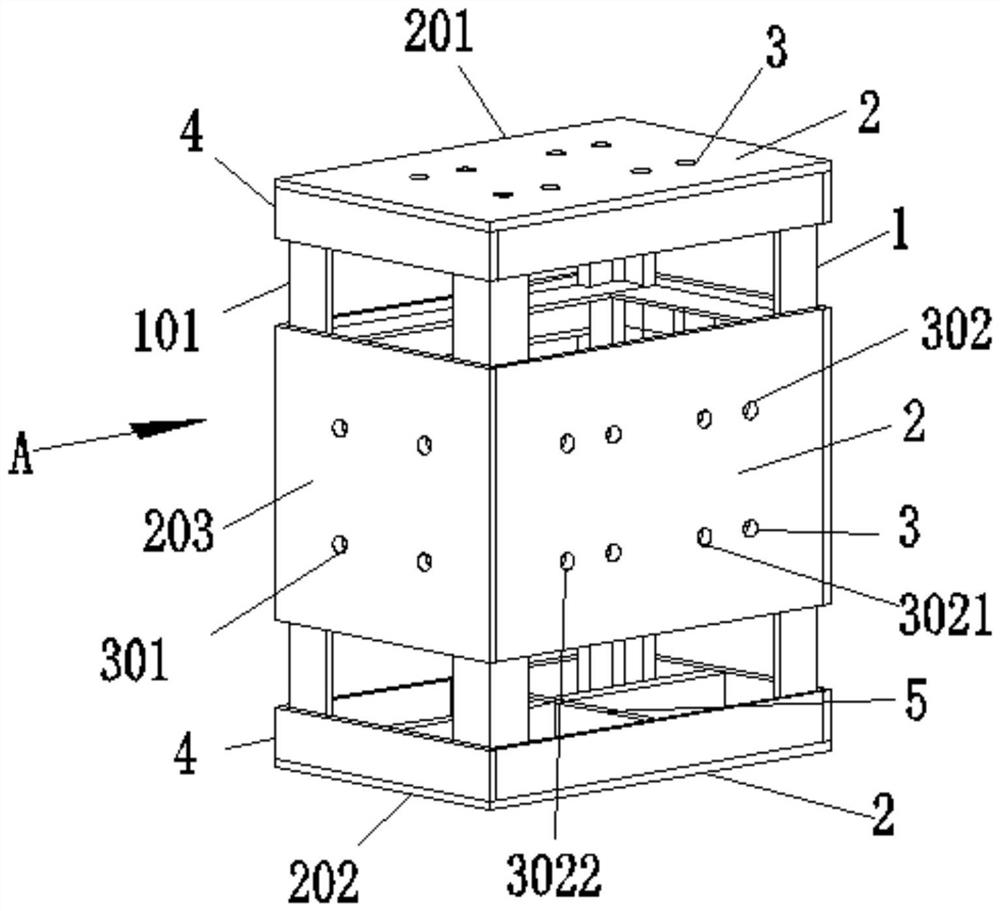

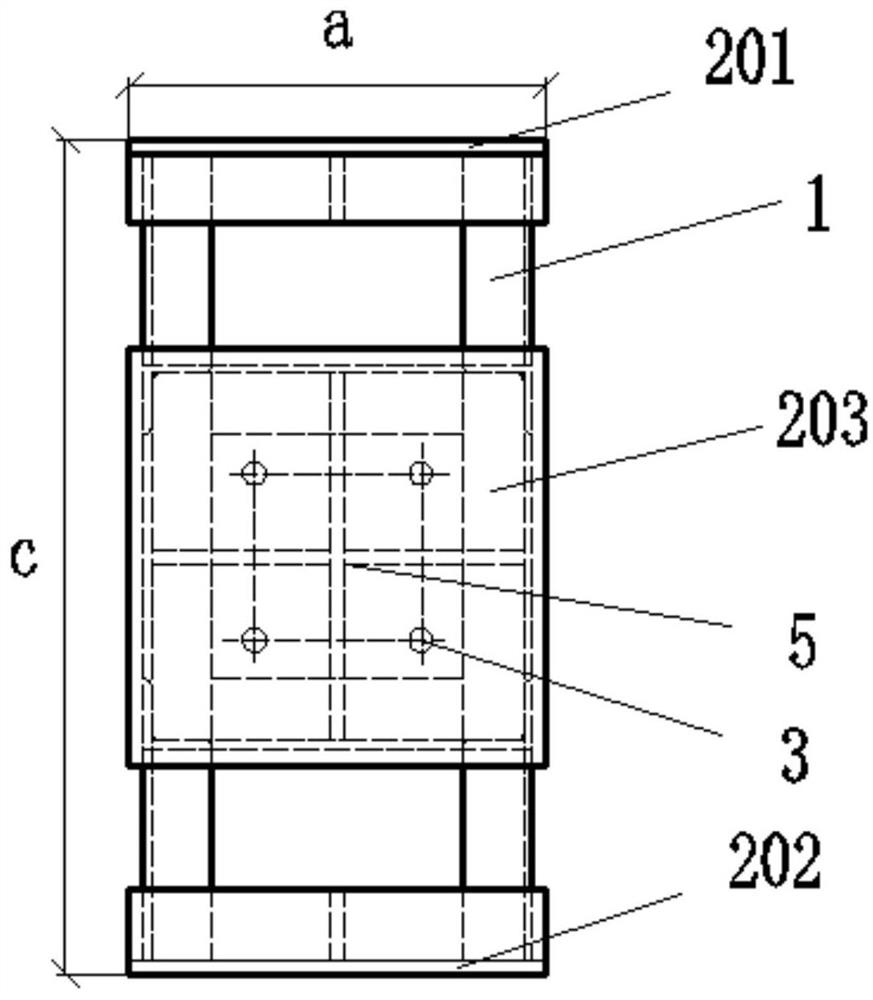

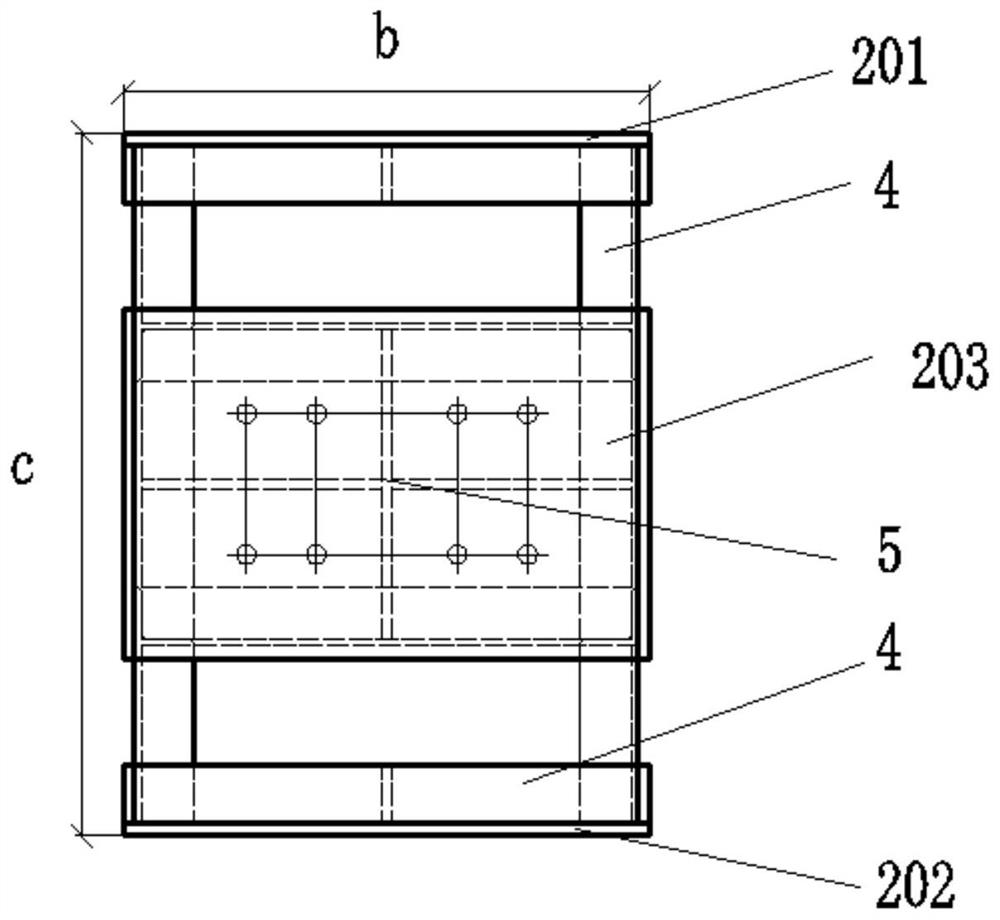

[0042] (Such as Figure 1-Figure 18 As shown) in the above embodiment, further: the cube frame 1 is a cuboid structure, and its length b, width a, and height c are all unequal.

[0043] Specifically: when using a steel structure modular support unit, take length b=900, width a=600mm, height c=1200mm as an example: as Figure 5-Figure 10 The three usage states shown can respectively meet the support requirements of three heights of 1200mm, 900mm, and 600mm respectively. When used as two steel structure modular support units, it can meet the support requirements of three heights of 2100mm, 1800mm and 1200mm.

[0044] In the above embodiment, further: the cube frame 1 is a cube structure with equal length, width and height.

[0045] It can be seen that when the cube frame 1 is a cube structure, the support requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com