Ozone disinfection machine

A disinfection machine and ozone technology, applied in disinfection, construction, water supply equipment and other directions, can solve the problems of low disassembly and assembly efficiency, cost a lot of man-hours, disassembly and assembly difficulties, etc., so as to reduce the space occupied by pipelines and save the space occupied , The effect of saving the use of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following is attached Figure 1-23 The application is described in further detail.

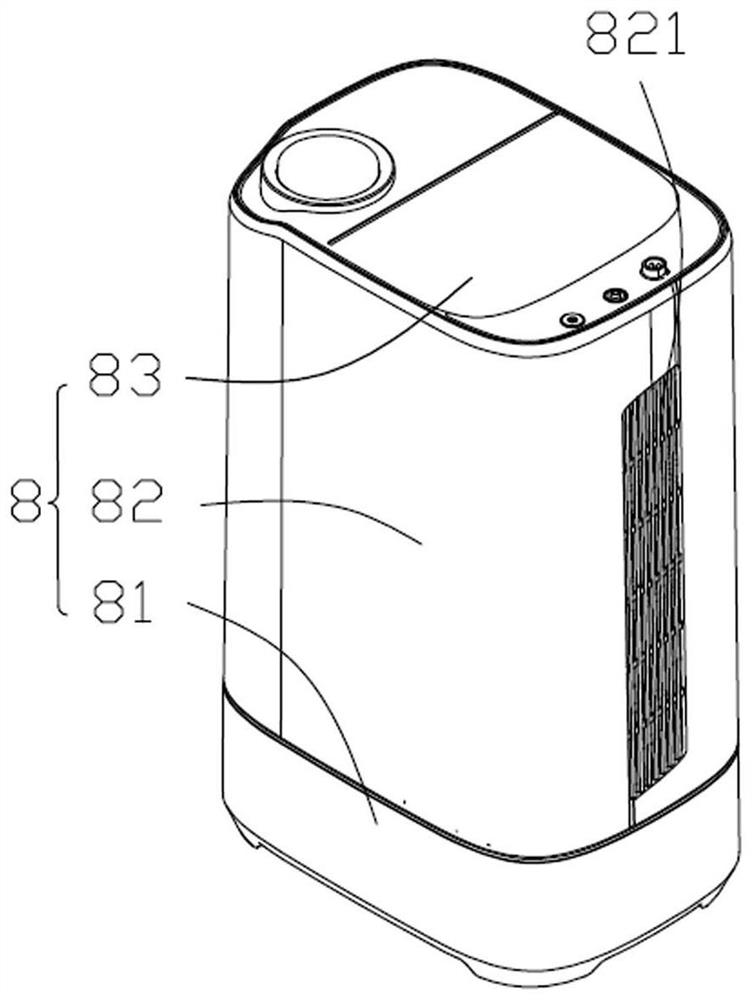

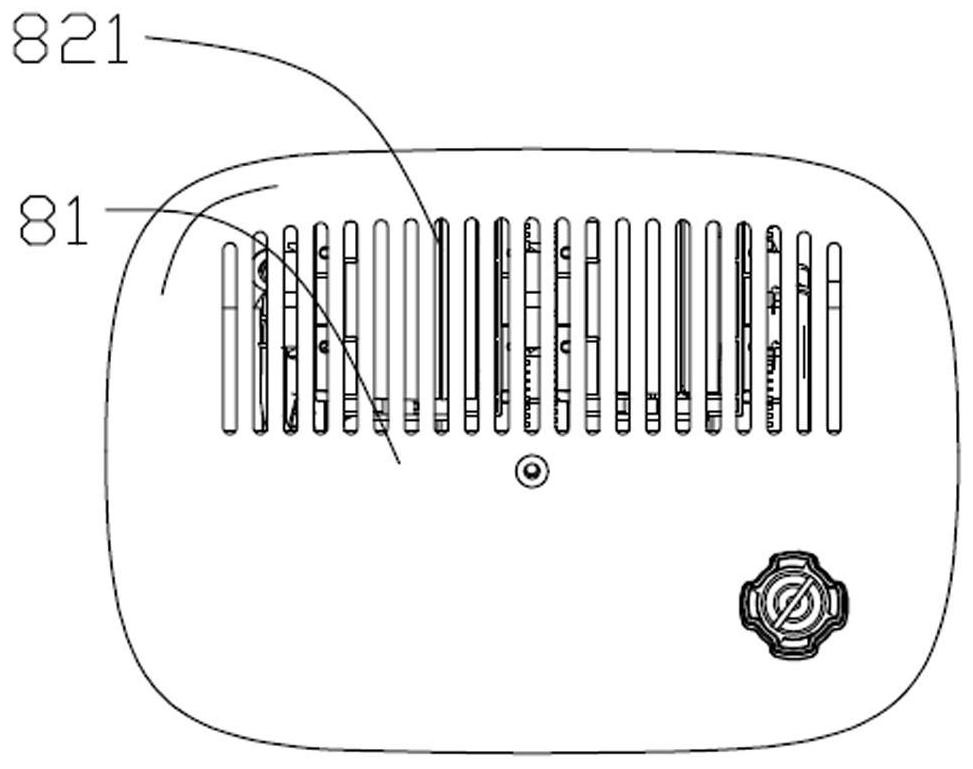

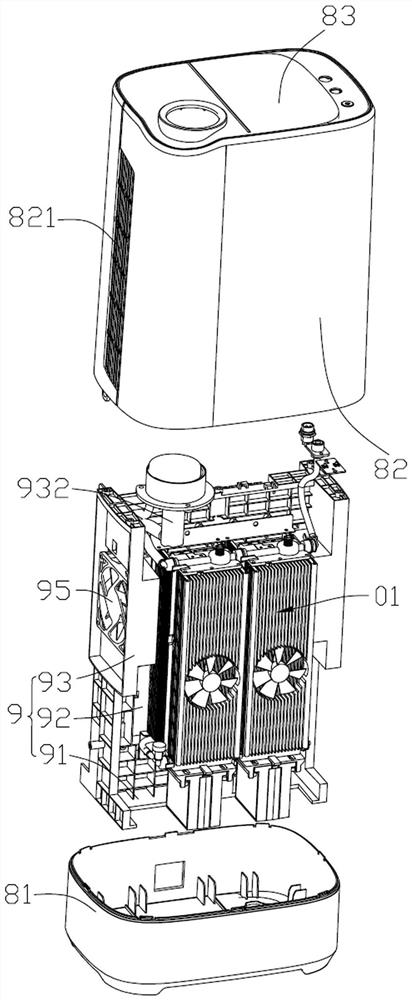

[0060] The embodiment of the present application discloses an ozone disinfection machine. refer to figure 1 and figure 2 , the ozone sterilizer includes a casing 8, a mounting frame 9 and an ozone generating transmission device 01; the casing 8 includes a lower casing 81, an upper casing 82 and an upper cover 83, the upper casing 82 is vertically arranged, and the bottom surface of the upper cover 83 is provided with a cooling grid Grille 821, the bottom edge of the upper case 82 is fastened on the top edge of the upper case 82, the symmetrical sides of the upper case 82 are also provided with cooling grilles 821, the upper cover 83 is fastened on the top edge of the upper case 82; the mounting frame 9 includes Plate 92, reinforcement plate 93 and receiving plate 91, the receiving plate 91 is horizontally arranged on the inner bottom surface of the lower shell 81, the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com