Cloth and water distributor of flat plate filter and flat plate filter

A cloth water distributor and filter technology, which is applied in the directions of mobile filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problem of inability to adjust the water volume in real time, and achieve the prevention of material accumulation and scarring, good filtering effect, Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

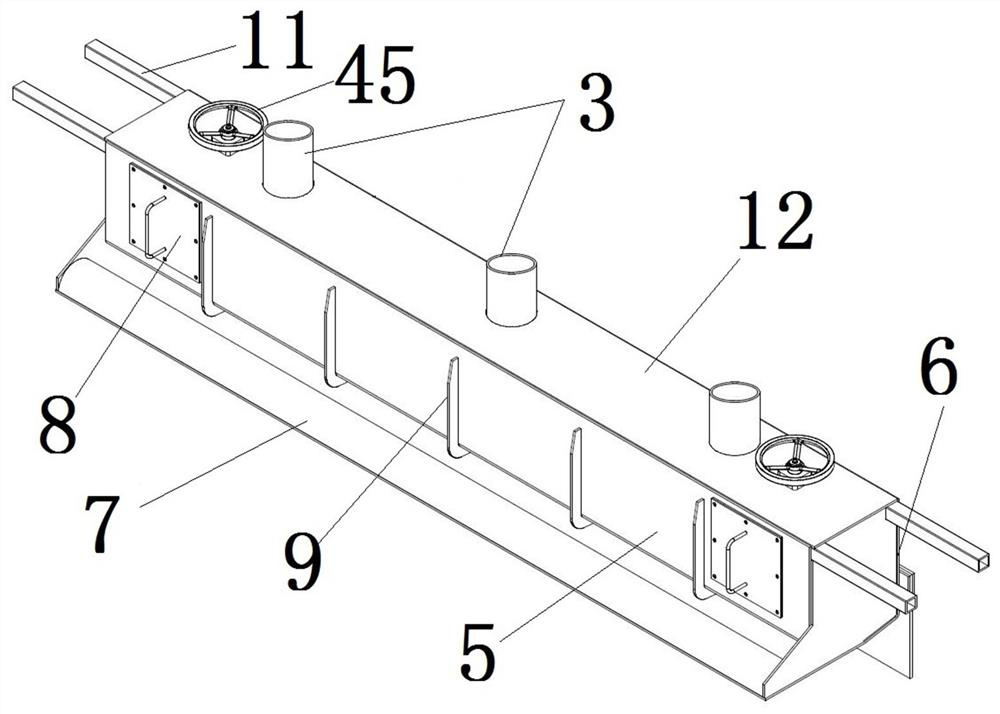

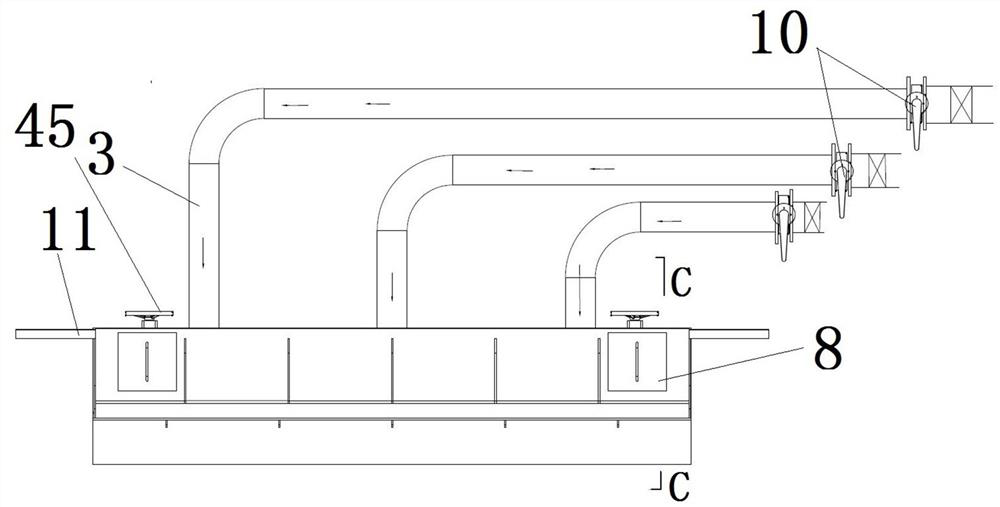

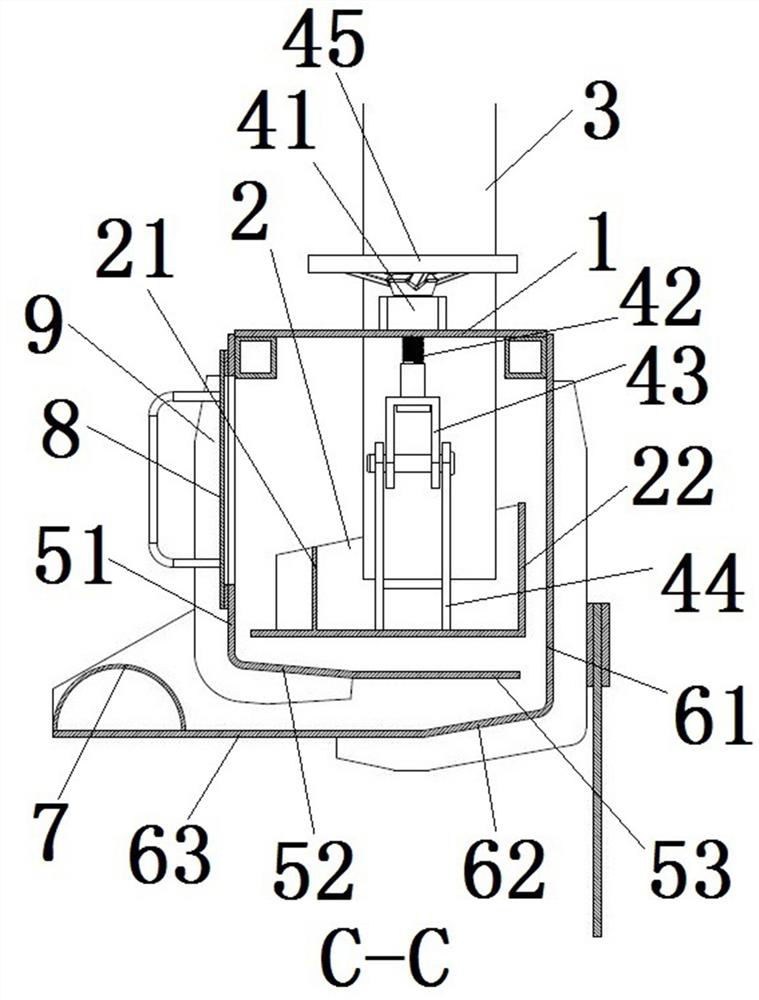

[0035] The flat plate filter includes the structure such as Figure 1-Figure 4 The cloth water distributor of the flat plate filter shown in the figure is installed above the flat plate along the radial direction of the flat plate when in use, and is used for distributing water and cloth to the flat plate. The water device is mainly composed of a fixed frame 1, a plurality of feeding pipes 3, an overflow tank 2 and two lifting adjustment mechanisms. The fixed frame 1 includes a top plate 12 and two reinforcing pipes 11 fixed on the lower side of the top plate 12, and the overflow tank 2. It can be lifted and lowered by the lifting adjustment mechanism at both ends. It is installed under the fixed frame 1. There are a plurality of passage holes for the feeding pipe 3 to pass from top to bottom on the top plate 12. The feeding pipe 3 is used to feed the overflow tank 2. Feed slurry. The overflow tank 2 comprises a bottom plate, two end side plates, an overflow side plate 21, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com