Automatic assembling equipment for plywood handicraft parts

An automatic assembly and handicraft technology, applied in the field of handicrafts, can solve the problems of low grinding efficiency, achieve the effect of reducing processing steps, improving efficiency, and reducing tape fixing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

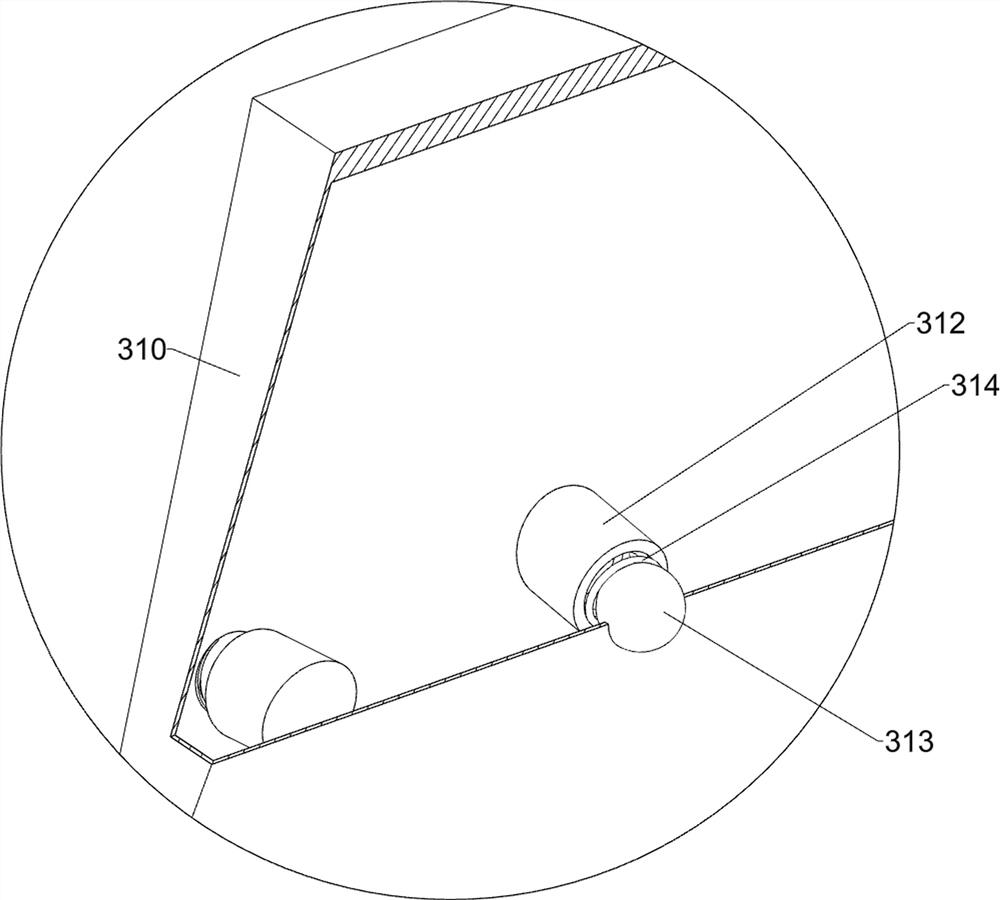

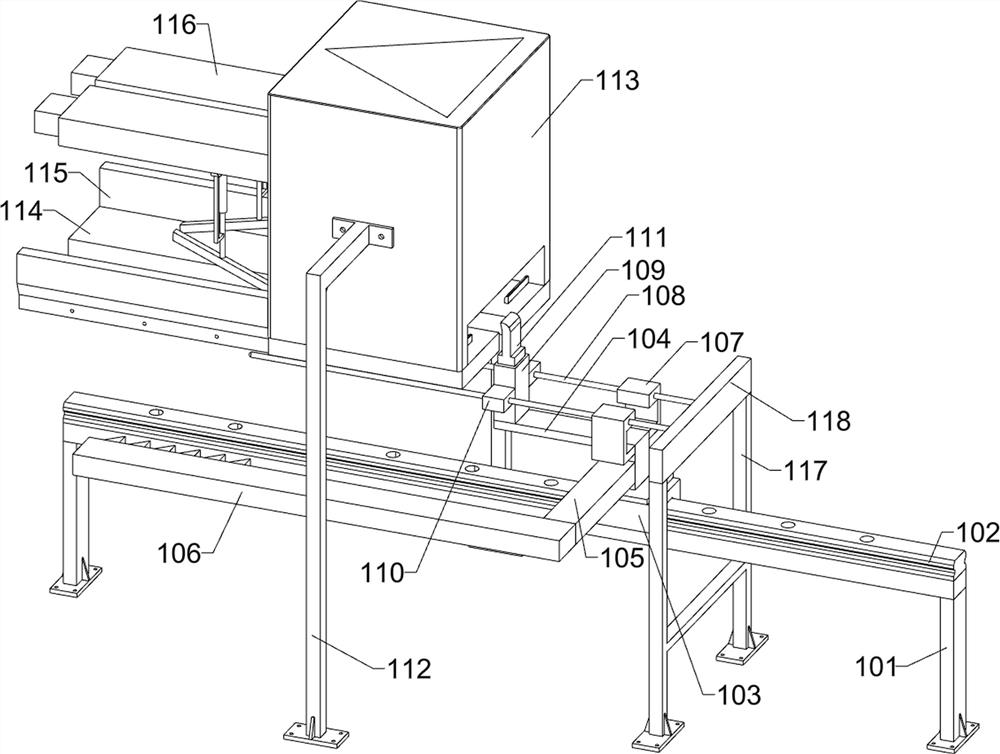

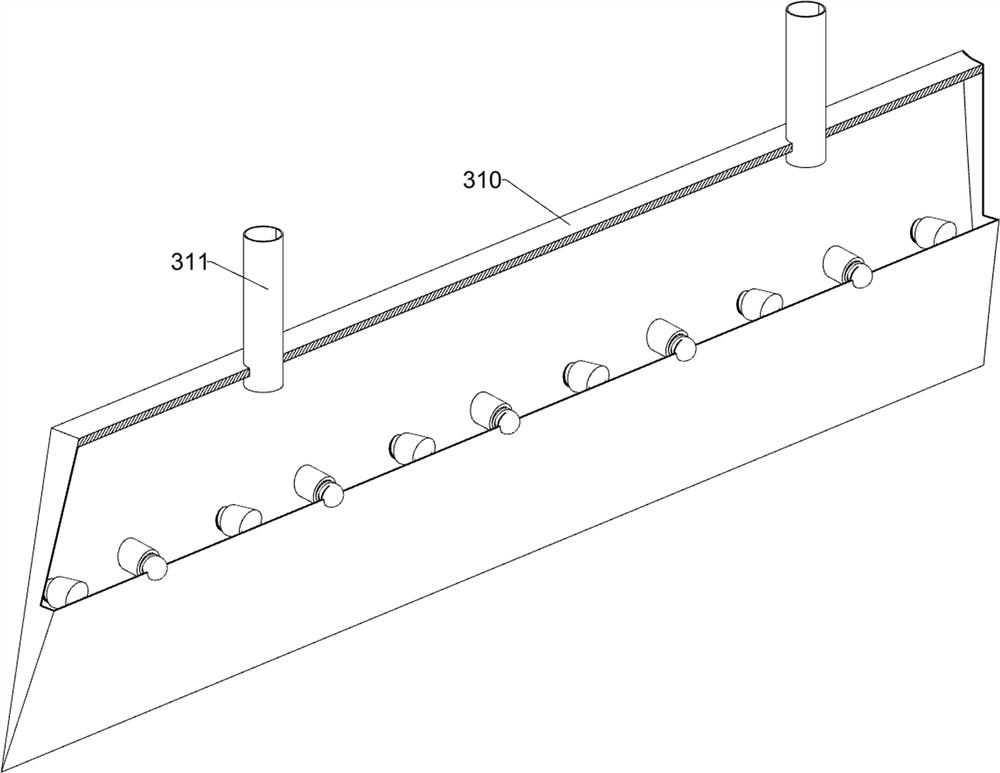

[0033] An automatic assembly equipment for plywood handicraft parts, such as Figure 1-14 As shown, it includes a bottom frame 1, a gantry frame 2, a plate-setting assembly, a gathering assembly and a glue-coating assembly; the upper left part of the bottom frame 1 is fixedly connected with the gantry frame 2; the upper right part of the bottom frame 1 is installed with a plate-setting assembly ; The left part of the upper side of the underframe 1 is equipped with a gathering component; the upper part of the gantry frame 2 is equipped with a gluing component;

[0034] The board assembly includes a first support frame 101, an electric guide rail 102, an electric slider 103, a first fixed frame 104, a first fixed plate 105, a mounting plate 106, a first limit block 107, a slide rod 108, and a limit sleeve 109, the second limit block 110, push block 111, support plate 112, charging box 113, receiving plate 114, first limit plate 115, second support frame 117, baffle plate 118, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com