Automatic component welding equipment for electrical engineering

A technology of automatic welding and electrical engineering, applied in welding equipment, metal processing equipment, metal processing, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

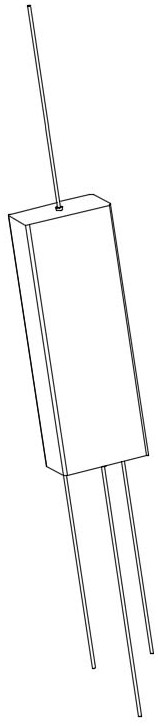

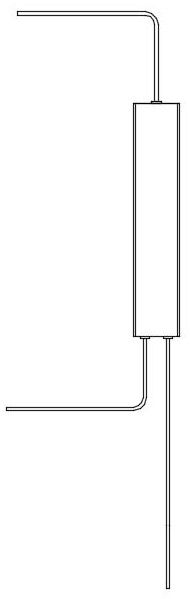

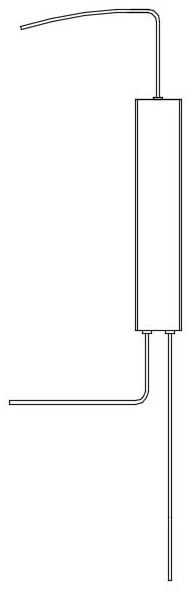

[0037] Reference attached Figure 5-Figure 11 , in this embodiment, an automatic welding equipment for electrical engineering components is proposed, which includes a conveying device 100 for conveying circuit boards and a material transfer clamping device 500. The circuit board is flat on the conveying device 100 facing upwards. lying down;

[0038] Along the conveying direction of the conveying device 100, a feeding device 200 and a bending device 300 for transferring the components one by one to the transfer and clamping device 500 are arranged in sequence, and are used for welding the two leads of the tail ends of the components to the front side of the circuit board. The upper soldering device 400, the upper soldering device 400 for pushing down the vertical components and the flat-lying device 600, the lower soldering device 700 for soldering the leads passing through the through holes of the circuit board to the reverse side of the circuit board, the feeding device 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com