Reloading device for tower type disk saw and working method

A circular saw and tower-type technology, applied in the field of stone processing machinery and equipment, can solve the problems of low production efficiency, high labor intensity, time-consuming and laborious, etc. of stone slabs, and achieve simplification of manual replacement steps, low labor costs, and safety assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

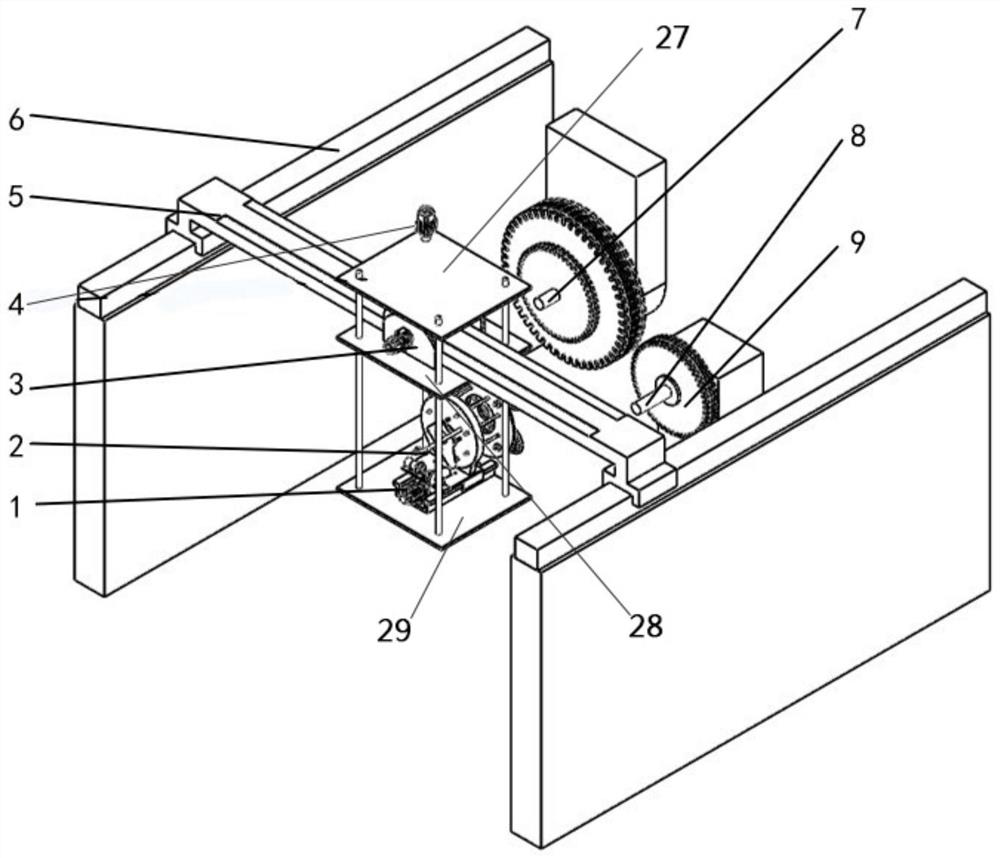

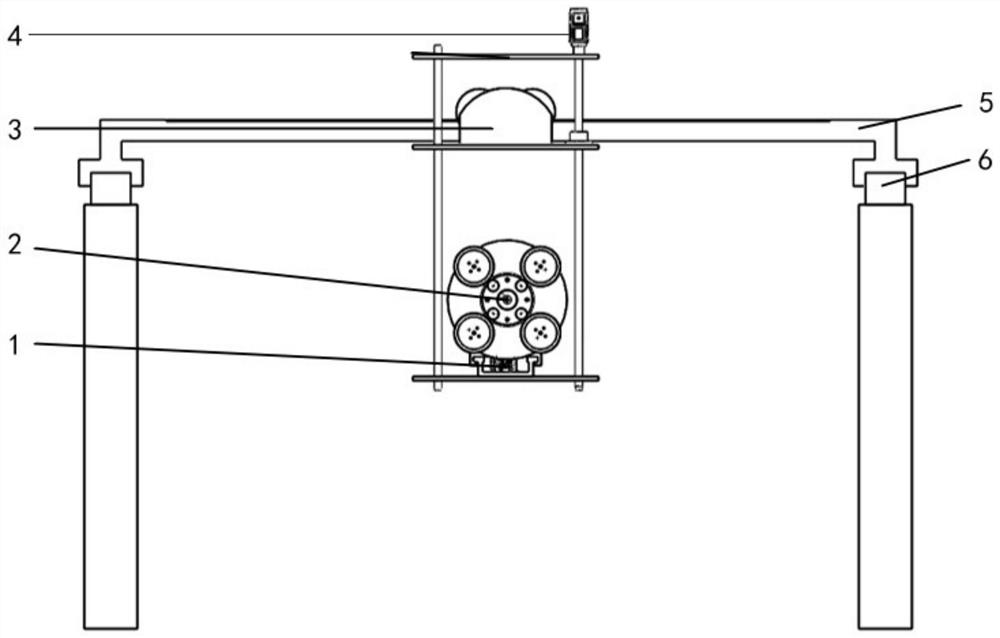

[0053] As an embodiment, the replacement mechanism also includes a first connecting plate 27, a second connecting plate 28 and a third connecting plate 29; the first connecting plate 27, the second connecting plate 28 and the third connecting plate 29 are parallel to each other Set, connect by connecting rod 30;

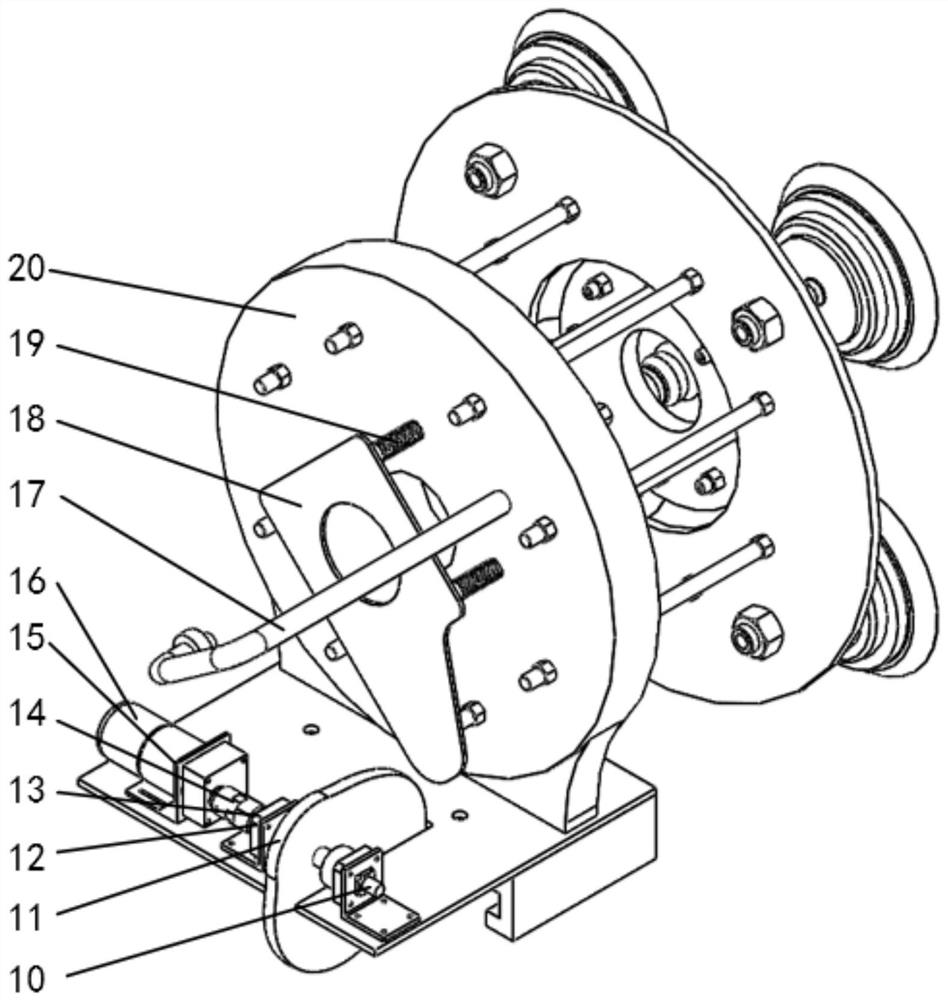

[0054] The first driving mechanism 3 is arranged on the second connecting plate 28 and is connected with the beam 5; the second driving mechanism 4 is arranged on the first connecting plate 27, and the second driving mechanism 4 can drive the third connecting plate 29 to move up and down along the connecting rod 30 ; The third drive mechanism 1 is set on the third connecting plate 29 , and the adsorption mechanism 2 is set on the third drive mechanism 1 .

[0055] As an embodiment, the first driving mechanism 3 includes a connecting plate frame 31, a first motor 32, a fixed wheel 33 and a roller 34; the bottom surface of the connecting plate frame 31 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com