Press fitting equipment for automobile shock absorber machining

An automobile shock absorber and press-fitting technology, which is applied to metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as inability to transport shock absorbers, increase the use of shock absorbers, and increase the labor intensity of operators. The effect of saving installation and fixing time, reducing labor intensity and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

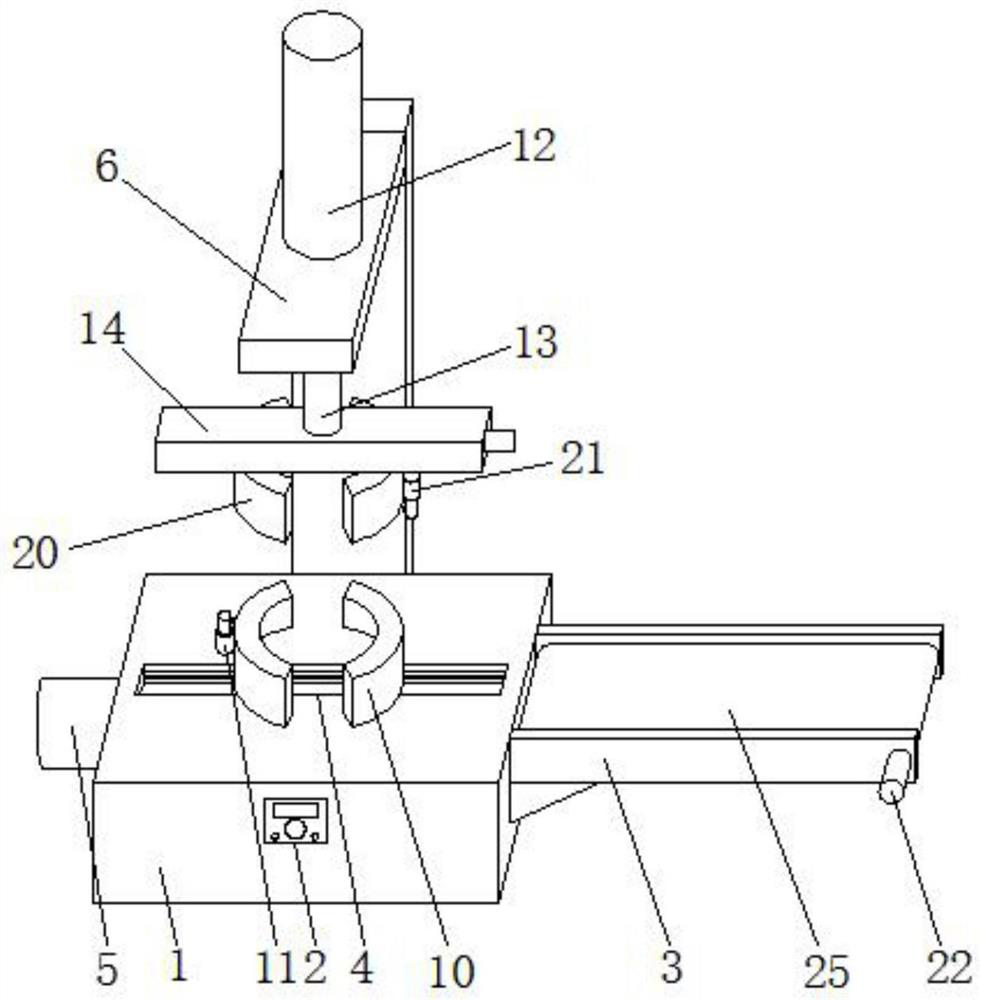

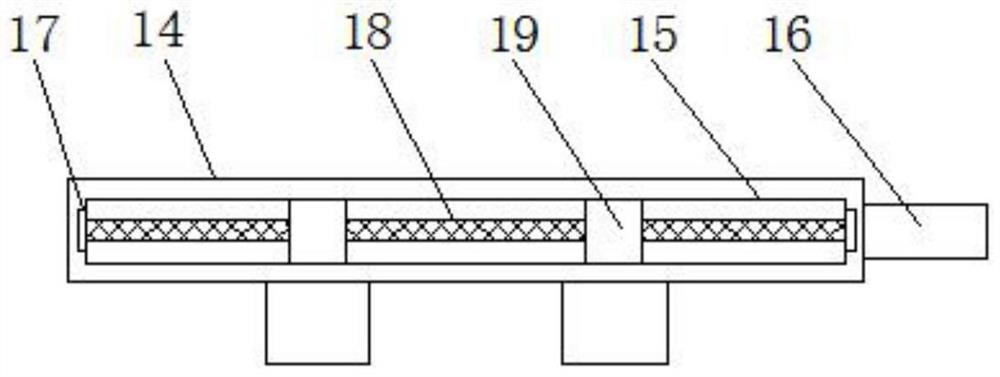

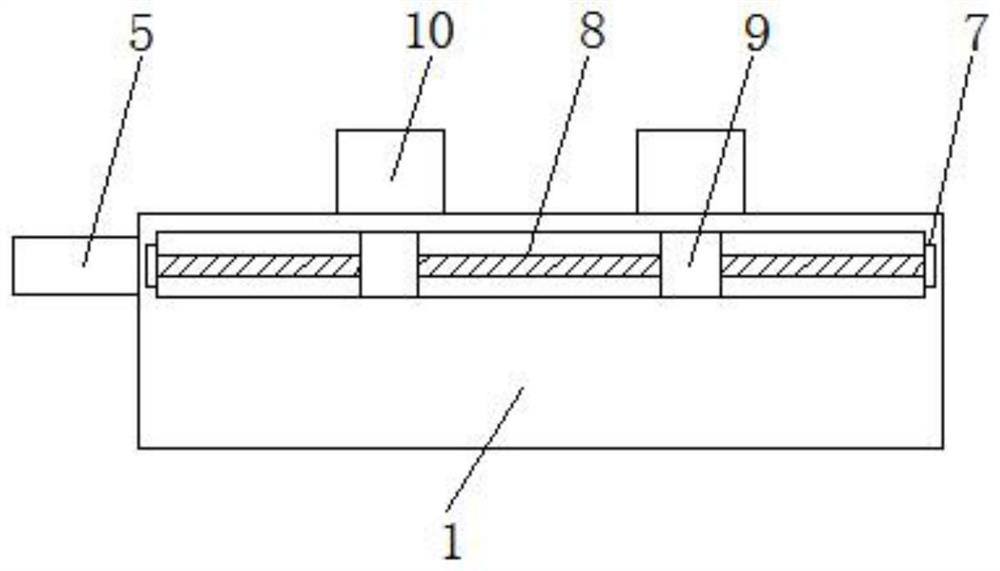

[0017] see Figure 1-Figure 4 , the present invention provides a technical solution: a press-fitting equipment for automobile shock absorber processing, including a press-fitting table 1, a controller 2, a transmission frame 3, and a first slide rail 4 are arranged on the press-fitting table 1 , a first servo motor 5 and a support frame 6, the controller 2 is fixedly connected directly in front of the press-fit table 1, the transmission frame 3 is fixedly connected to the right end of the press-mount table 1, and the first The slide rail 4 is located inside the pressing table 1, the first servo motor 5 is fixedly connected to the left end of the outer surface of the pressing table 1, and the support frame 6 is fixedly connected to the back of the pressing table 1 , the inside of the first slide rail 4 is connected to the first screw 8 through the first bearing 7, and the first screw 8 is connected to the first arc splint 10 through the first slider 9, and the first arc splint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com