Auxiliary equipment for intelligently sleeving heat shrinkage film on grinding wheel disc

An auxiliary equipment and heat shrinkable film technology, which is applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of low degree of automation, low efficiency, and difficulty in controlling the length of heat shrinkable film, so as to achieve convenient clamping and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

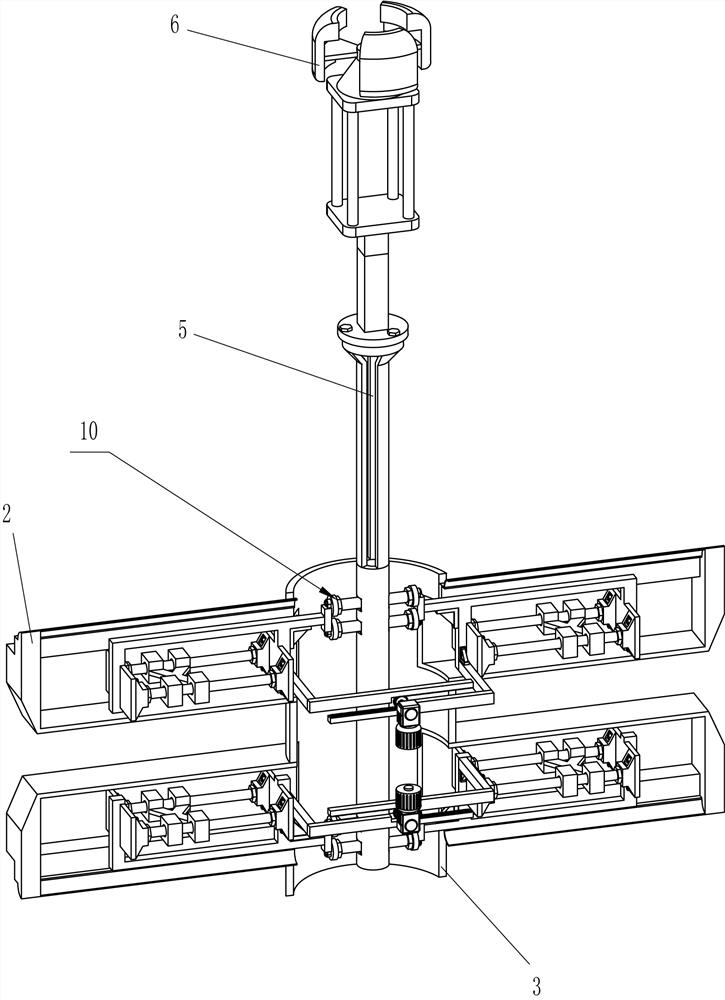

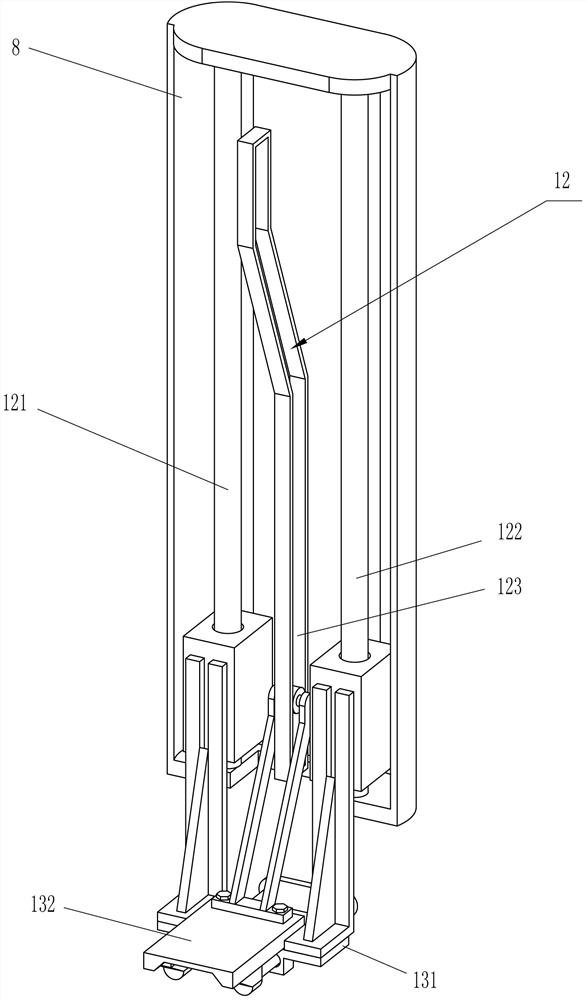

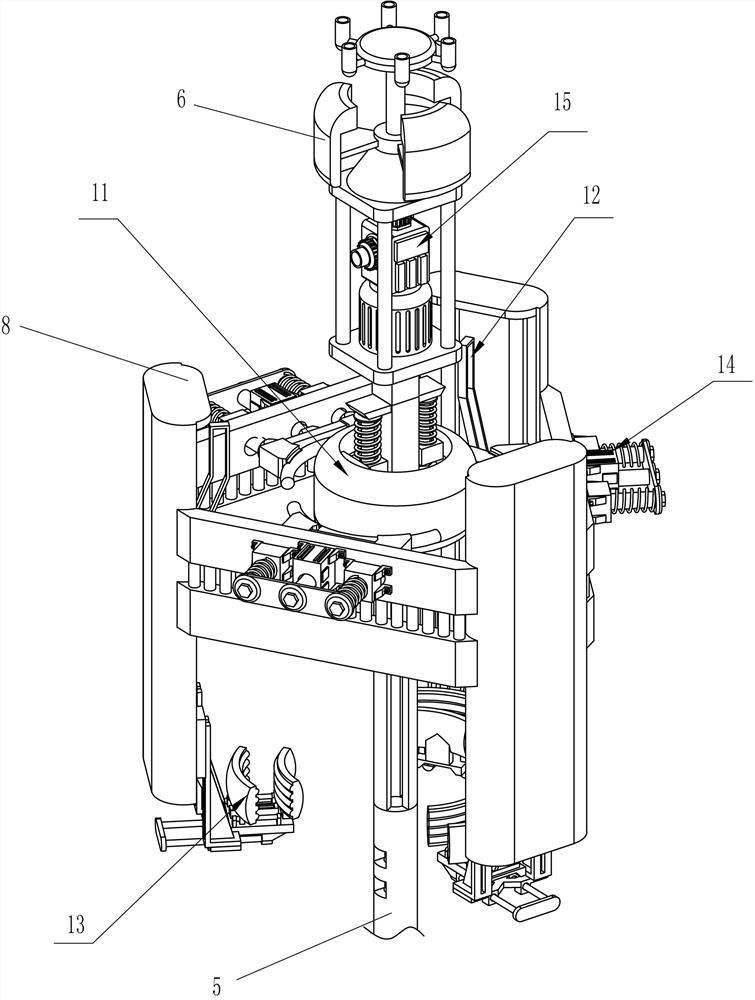

[0040] Such as Figure 1-5 As shown in the figure, an auxiliary equipment for intelligent heat-shrinkable film of a grinding wheel disc includes a bracket 1, an installation box 2, a relay pipe 3, a feeding pipe 4, a center rod 5, a guide frame 6, an installation ring 7, and a centering Frame 8, feeding device 9, supporting device 10, stabilizing device 11, lifting device 12, clamping device 13 and fusing device 14, specifically:

[0041] There are two sets of installation boxes 2 in the middle of the front side of the bracket 1, a relay pipe 3 is arranged between the installation boxes 2, a feeding pipe 4 is arranged on the lower side of the relay pipe 3, and a central rod 5 is arranged between the relay pipes 3. The central rod 5 is a structure with two sets of four positioning holes on the lower side, the upper side of the central rod 5 is provided with a guide frame 6, the upper side of the bracket 1 is provided with a mounting ring 7, and a centering frame 8 is provided bet...

Embodiment 2

[0044] Such as Figure 6-20 As shown, the feeding device 9 includes a first mobile pair 91, a first electric slide rail 92 and a discharge rack 93, specifically:

[0045] The inside of the feeding pipe 4 is provided with a first moving pair 91 and a first electric slide rail 92 , and a discharge rack 93 is arranged between the moving parts of the first moving pair 91 and the moving parts of the first electric sliding rail 92 .

[0046] When the above-mentioned embodiment is in operation, the emery wheel disc can be placed at the position of the discharge rack 93. When the control box 16 controls the operation and pause of the feeding device 9, the control box 16 will control the first electric slide rail 92 to drive its moving parts Move up and down, thereby drive discharging frame 93 to move up and down.

[0047] The supporting device 10 includes a second moving pair 101, a displacement frame 102, a positioning rod 103, a rack 104, a gear 105 and a driving motor 106, specifi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap