PVDF (Polyvinylidene Fluoride) solid fluorocarbon coating and preparation method thereof

A fluorocarbon coating, solid technology, applied in the direction of coating, etc., can solve the problems that the mechanical properties cannot meet the actual needs, the stain resistance and the thermal stability are not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

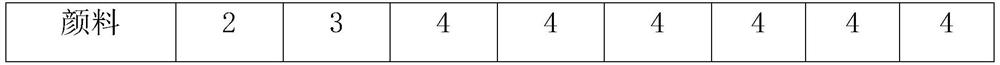

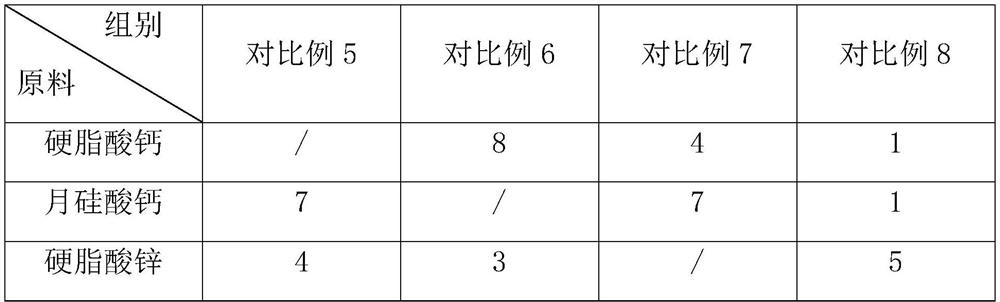

[0047] The preparation raw material of the PVDF solid fluorocarbon coating of embodiment 1-5, specifically as shown in table 1:

[0048] The preparation method of the PVDF solid fluorocarbon coating of embodiment 1-5, comprises the following steps:

[0049] Calcium stearate, calcium lauricate and zinc stearate with a weight ratio of 2:7:2 were placed in a ball mill and ball milled for 35 minutes at a temperature of 95°C to obtain a composite stabilizer with a particle size of 20 μm ;

[0050] PVDF polyvinylidene fluoride, fluororesin, acrylic resin, polyurethane and N,N-dimethylformamide are pre-mixed, and the conditions of the pre-mixing are: the stirring rate is 1500r / min, the time is 35min, and the temperature is At 65°C, mixture A was obtained;

[0051] Continue to add magnesium oxide, zinc oxide and the composite stabilizer to the mixture A, adjust the stirring frequency, stir evenly, stir at 80°C and keep it warm for 10 minutes to obtain the mixture B;

[0052]Continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com