A kind of preparation method of high-entropy steel-bonded cemented carbide with core-edge structure

A technology of steel-bonded hard alloy and edge structure, applied in the field of hard alloy, can solve the problems of difficult supply of raw materials, poor effect, high cost, etc., and achieve the effect of high hardness, high quality, and no deformation of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a high-entropy steel-bonded cemented carbide with a core-edge structure, comprising the following steps:

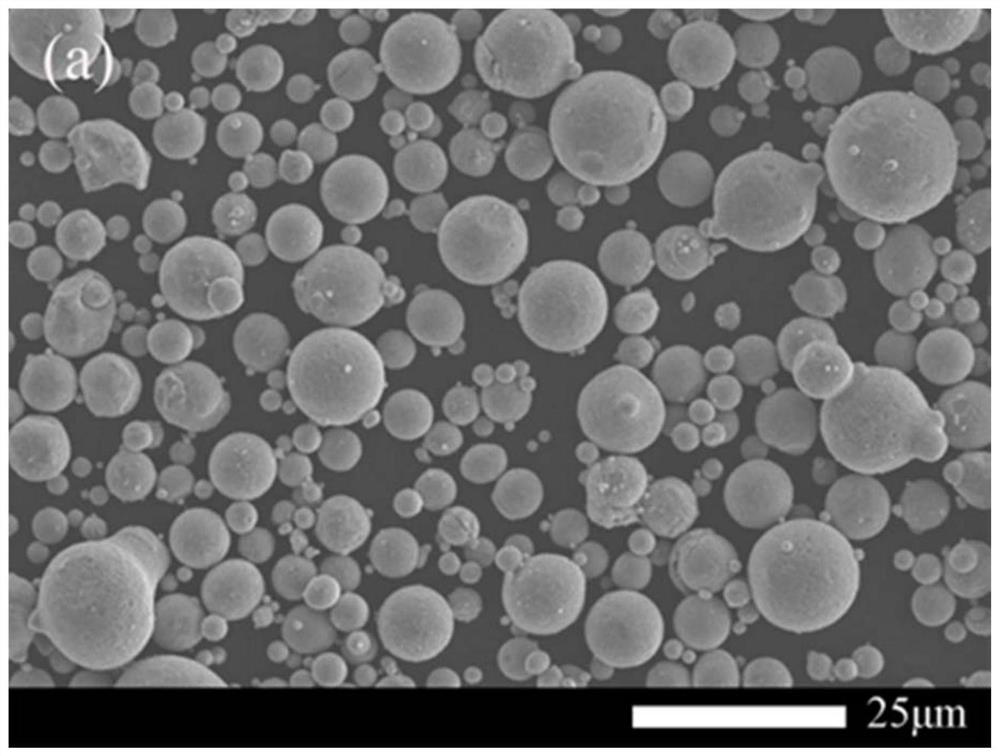

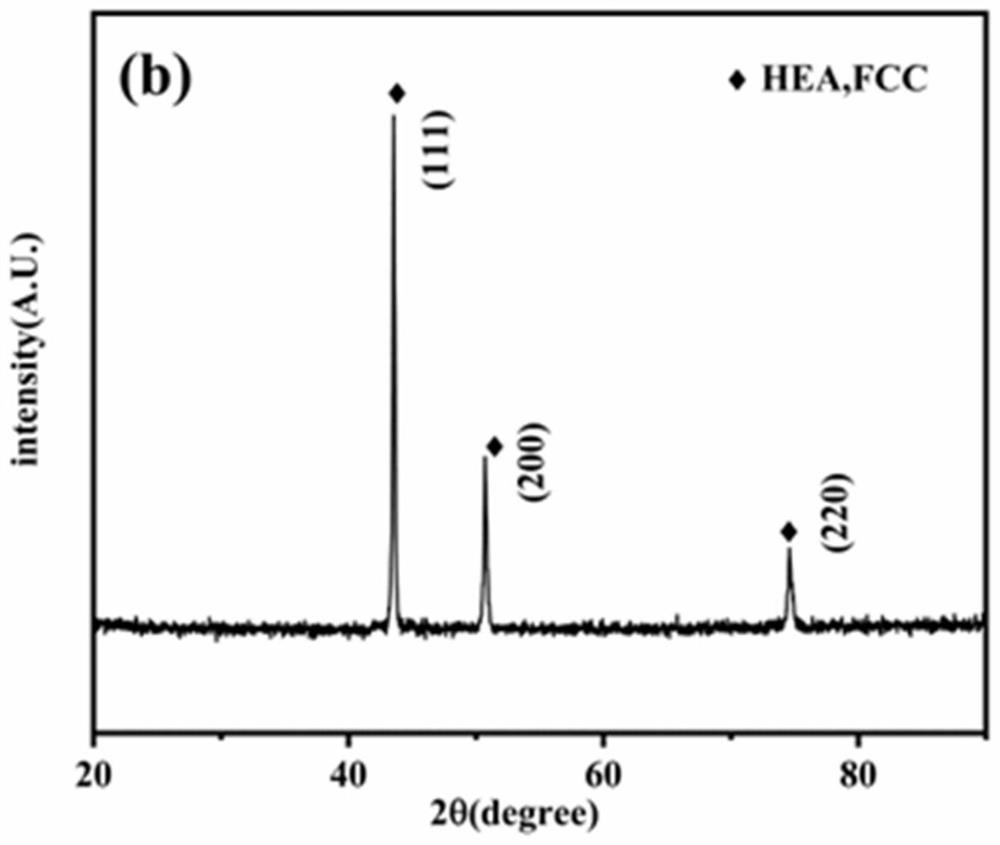

[0036] S1: Prepare high-entropy alloy powder of a single solid solution. Specifically, metal blocks of cobalt, chromium, iron, nickel, and manganese are weighed according to equiatomic ratio or near equiatomic ratio, and then put into an induction furnace for smelting, and the number of smelting is set to 5-6 times, the melted alloy liquid is injected into the atomizing nozzle, the alloy liquid is atomized into small droplets under the high-speed airflow, and finally the alloy powder is formed in the atomizing cylinder. The purity of the high-entropy alloy powder is ≥99.5%, and the oxygen content ≤0.12%, the average particle size is 25μm, see the micrograph of the alloy powder after atomization figure 1 , the results of XRD diffraction analysis can be found in figure 2 . Among them, Cr, Ni, Mn elements provide high hardness and high oxida...

Embodiment 2-5

[0051] The high-entropy cemented carbides of Examples 2-5 were prepared by adjusting the composition ratio by the preparation method of Example 1, and their properties were tested by the test method of Example 1. The test results are shown in Table 2:

[0052] Table 2 The performance test results of the corresponding products of embodiment 2-5

[0053]

[0054] It can be seen from the test results that the HSC cemented carbides obtained by the sintering process of the present application within a certain ratio range of the present application have greater advantages compared with standard cemented carbides in terms of density and hardness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com