Supported iridium-based catalyst thin layer and preparation method thereof

A catalyst and thin-layer technology, which is applied in the field of iridium-based catalyst preparation, can solve the problems of disappearance of array morphology and inability to meet the requirements of ordered electrode structure, etc., and achieve the improvement of mass specific activity, mass specific activity and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of ordered WO by hydrothermal method x carrier

[0042] To prepare a tungstic acid solution, first weigh 1.25 g of tungstic acid, add 10 ml of 30 wt% hydrogen peroxide, add water to dissolve 30 ml of water, and stir at 85 °C for 30 min to form a milky white tungstic acid solution, which is diluted with water so that the concentration of tungstic acid is 0.05molL -1 .

[0043]To prepare a solution for hydrothermal reaction: 0.056 g of thiourea and 0.064 g of maleic acid were weighed in turn, 3.2 mL of 3M hydrochloric acid solution was weighed, 4.8 mL of water and 30.4 mL of acetonitrile were added as solvents, and the mixture was stirred for 30 min. The prepared tungstic acid solution was added, and the stirring was continued for 60 min to complete the preparation of the reaction solution.

[0044] Cut the pure tungsten sheet into 2.5*5.0cm 2 sonicated with ethanol and deionized water for 20 min in turn, then placed in 80°C, 25% hydrochloric acid solu...

Embodiment 2

[0055] (1) Prepare ordered WO according to the hydrothermal method of Example 1 x carrier

[0056] (2) Preparation of iridium-based catalyst thin layer

[0057] Cyclic voltammetry current, the potential scanning range is -0.4 ~ 0.05V vs SCE, the scanning speed is 100mVs-1, and the number of scanning is 100 times. Other processes are the same as those shown in Example 1. After scanning, take out the electrode, wash it in deionized water for 2 to 3 times, and dry it;

[0058] Heat treatment: After the deposition, the electrode sheet loaded with the iridium-based catalyst was annealed at 400 °C in an argon atmosphere for 2 h, and the heating rate was 2 °C min -1 . An iridium-loaded WOx array electrode was obtained.

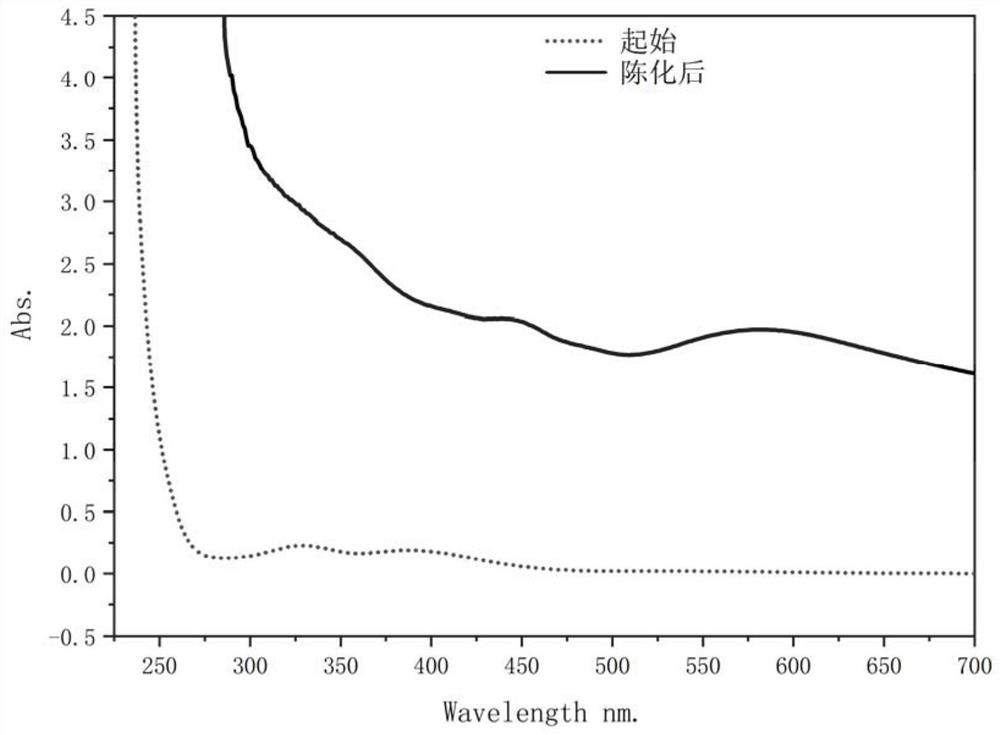

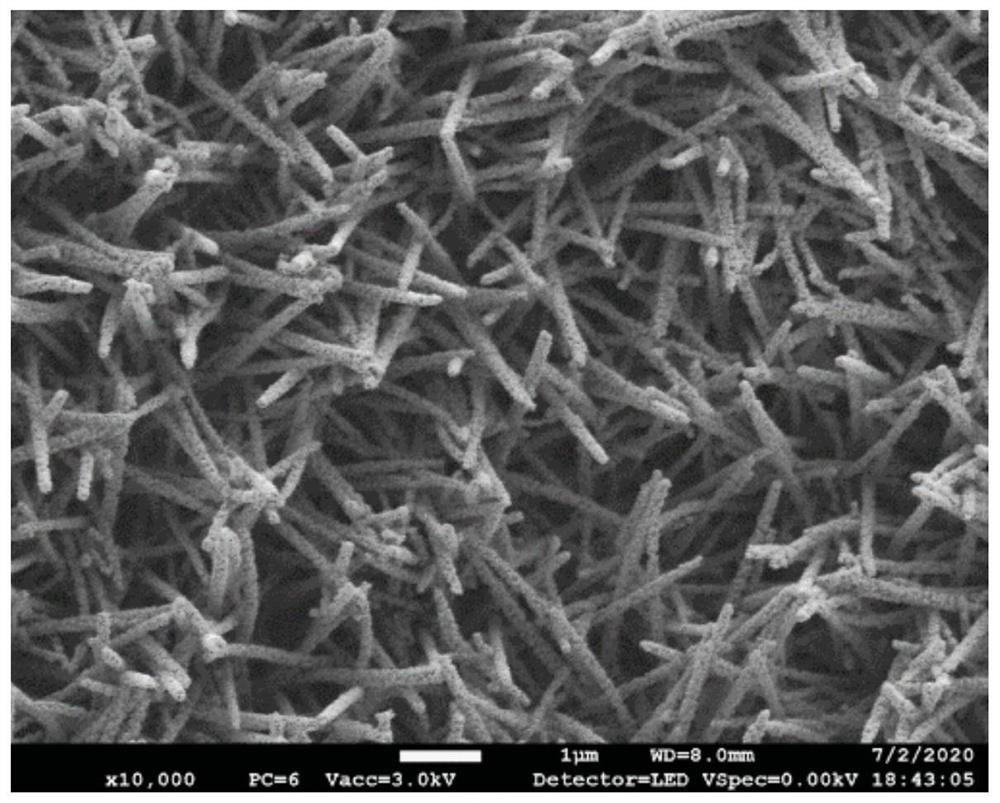

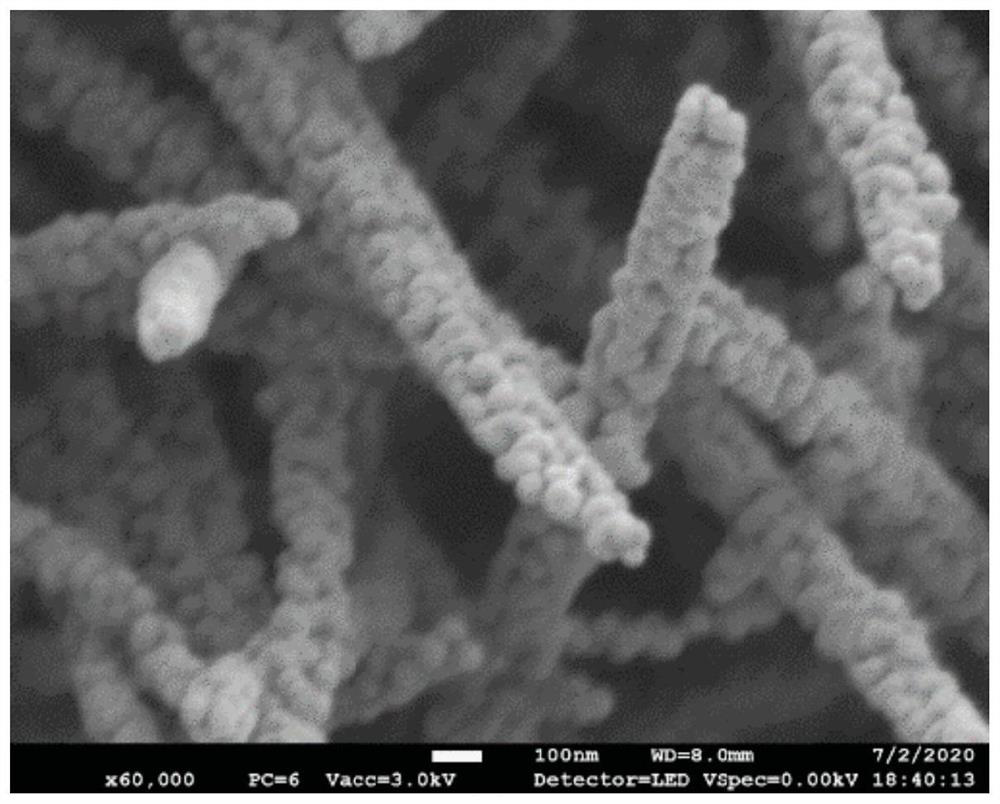

[0059] Ir@WO was prepared in this example x Array electrode structures such as Figure 8 and 9 As shown, the iridium-based catalyst was distributed as a spherical monolayer on the surface of the array, and the diameter of the catalyst particles was about 20 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com