Geotechnical grid laying operation device

A working device and geogrid technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as workers slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

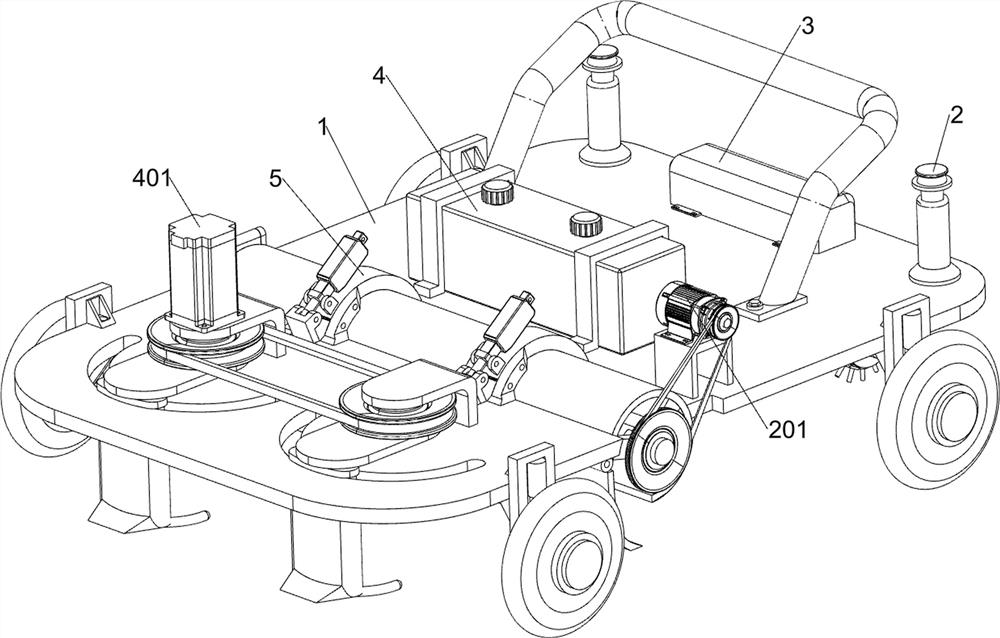

[0030] A geogrid laying operation device, according to Figure 1-13 As shown, it includes a car body 1, inserting nails 2, driving group 3, battery 4, connecting frame 5, collecting mechanism, laying mechanism and cleaning mechanism; the rear of the car body 1 is symmetrically detachably connected with two inserting nails 2 The rear part of the car body 1 is connected with a driving group 3, and the driving group 3 is located between two nails 2; the middle part of the car body 1 is connected with a battery 4; the front part of the car body 1 is symmetrically connected with two connecting frames 5 The car body 1 is connected with a collecting mechanism; the lower surface of the rear part of the car body 1 is connected with a laying mechanism; the front part of the car body 1 is connected with a cleaning mechanism.

[0031] Two motors are arranged symmetrically in the driving group 3 for driving the laying mechanism to run.

[0032] When working, the car body 1 is placed on th...

Embodiment 2

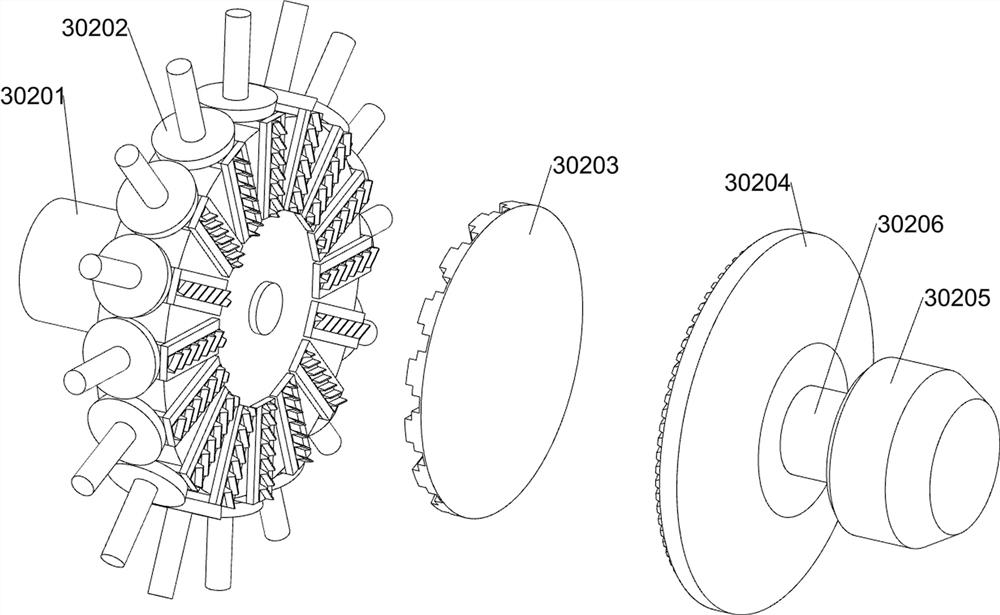

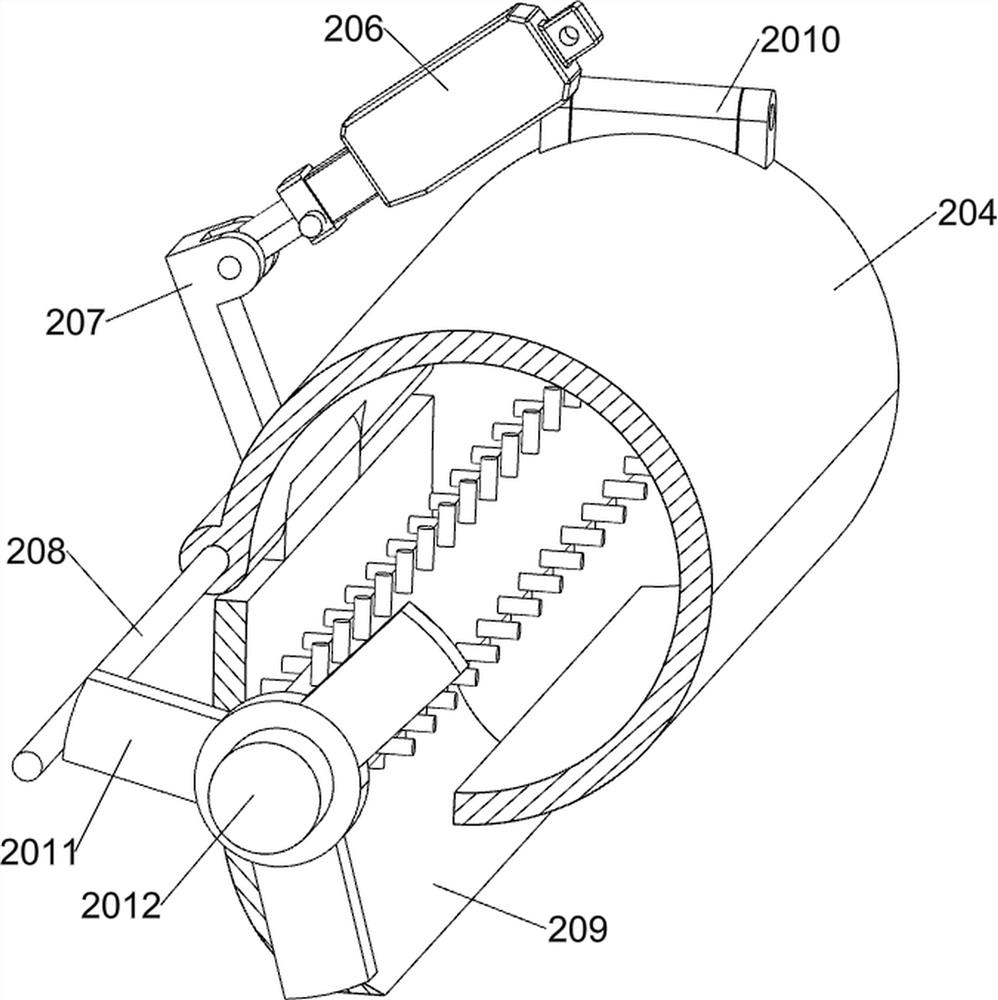

[0034] On the basis of Example 1, according to figure 1 with Figure 4-13 As shown, the collection mechanism includes a first motor 201, a first transmission wheel 202, a second transmission wheel 203, a collection cylinder 204, a first bracket 205, an electric push rod 206, a connecting shaft seat 207, a rotating rod 208, and a protective plate 209 , pinch plate 2010, second support 2011 and winding roller 2012; The middle part right side of car body 1 is welded with first support 205; The upper surface bolt of first support 205 is connected with first motor 201; The output of first motor 201 The shaft is fixedly connected with the first transmission wheel 202; the front part of the car body 1 is welded with a collection tube 204; the collection tube 204 is fixedly connected with the connecting frame 5; an electric push rod 206 is respectively installed on the two connecting frames 5; each Each telescoping part of the electric push rod 206 is connected with a connection shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com