Opening and closing type fastening nut and die casting machine

A kind of tightening nut, opening and closing technology, applied in the direction of nuts, threaded fasteners, bolts, etc., can solve the problem of easy wear and tear of tightening nuts when opening and closing, and achieves direct force, high opening and closing accuracy, and good guide limit. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

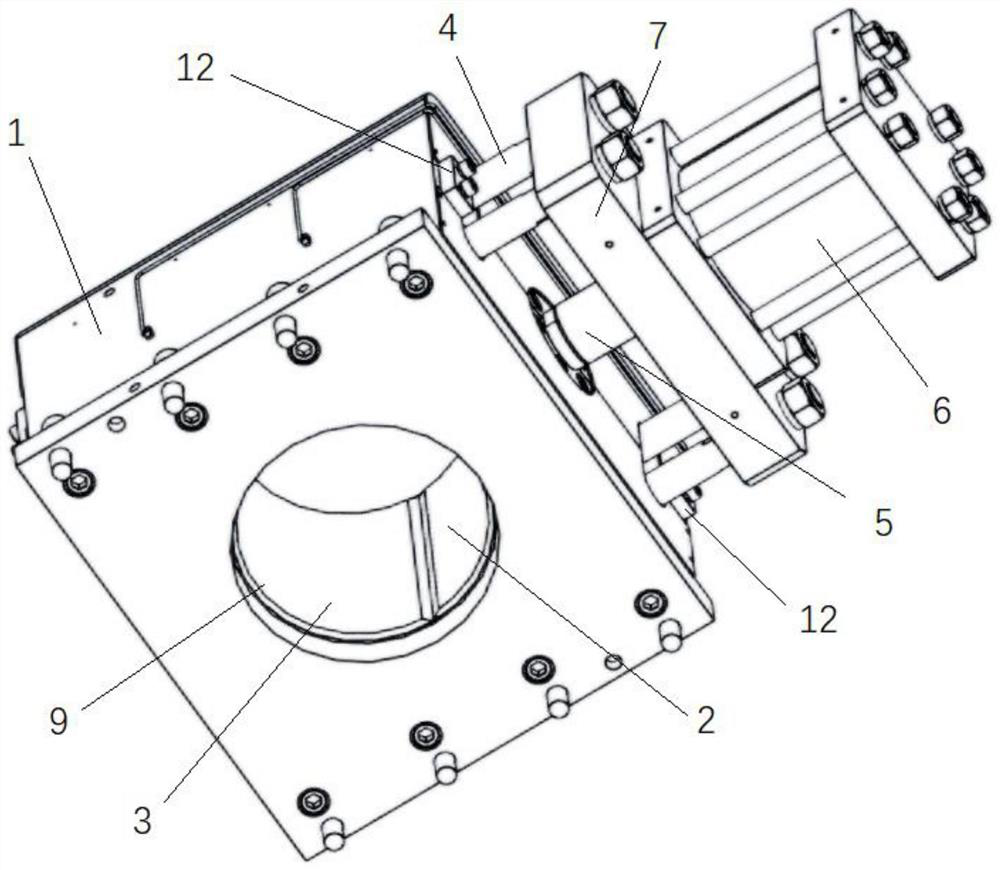

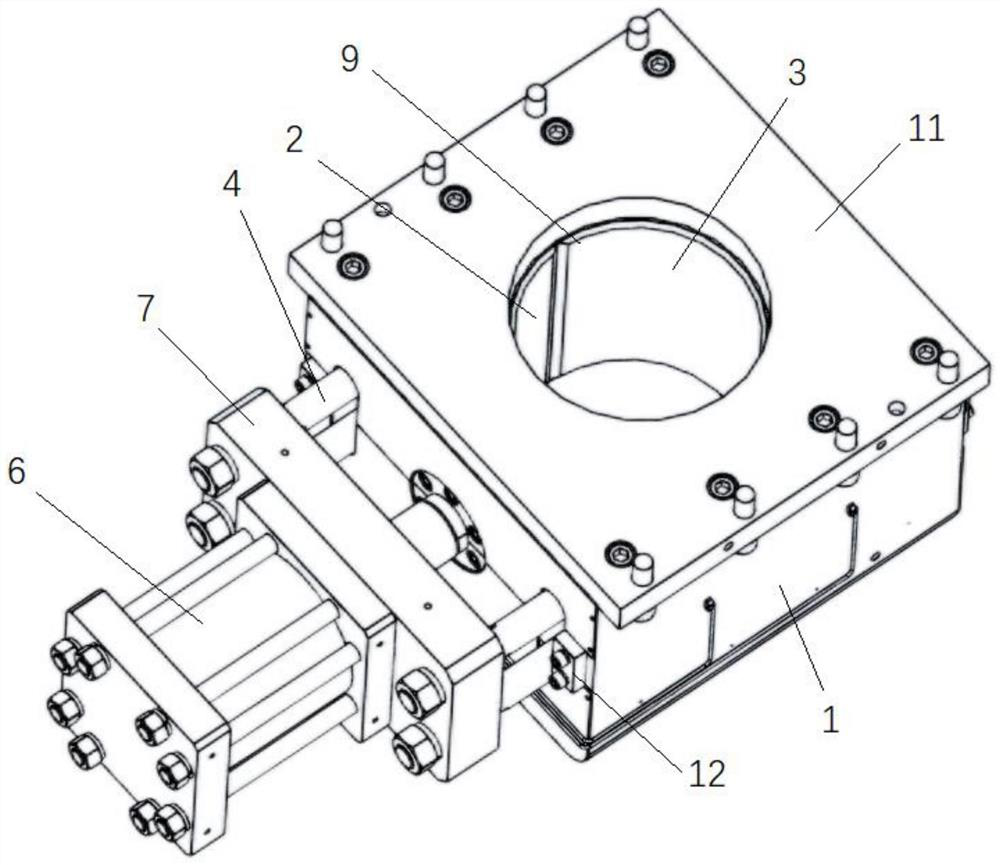

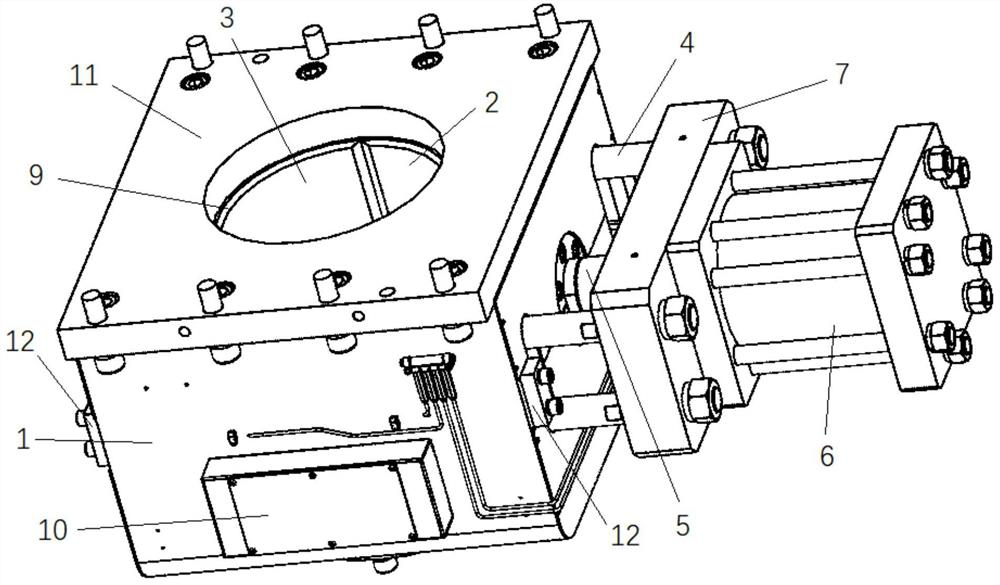

[0045] Embodiment 1: as Figure 4-5 As shown, the active part is the telescopic rod 5 of the oil cylinder or the cylinder, and the end of the telescopic rod 5 is directly fixedly connected with the first half nut 2. Specifically, the end of the telescopic rod 5 is fixed with an enlarging head, and the enlarging head is connected with the first half nut 2. The first half nut 2 fits and is fastened by bolts. The passive part is the cylinder liner 6 of the oil cylinder or the cylinder, and the cylinder liner 6 is fixedly connected with the second half nut 3 . The telescopic rod 5 is driven to telescopically slide in the cylinder sleeve 6 by a compressed medium, which may be compressed air or hydraulic oil.

[0046] At the same time, if Figure 1-3 As shown, the limiting structure includes at least one pair of limiting blocks 12, the first half nut 2 and the second half nut 3 are located between a pair of the limiting blocks, and the first half nut 2 and the When the second hal...

Embodiment 2

[0058] Embodiment 2: a kind of open and close fastening nut, such as Figure 1-3 As shown, the difference between it and Embodiment 1 is that in this embodiment, the active part is an air cylinder or an oil cylinder, and the end of the telescopic rod 5 of the air cylinder or oil cylinder is fixedly connected with the first half nut 2; the passive part is It is a fixed plate 7, which is fixedly connected with the second half nut 3.

[0059] Specifically, the fixed plate 7 is provided with a through hole, and one end of the telescopic rod 5 is located in the cylinder liner of the cylinder or the oil cylinder, and the other end passes through the hole and is connected with the first half nut, wherein the end of the telescopic rod 5 An enlargement head is fixed, and the enlargement head fits with the first half nut 2 and is fastened by bolts. The cylinder liner 6 of the air cylinder or oil cylinder is fixedly connected with the fixed plate 7, that is, the telescopic rod 5 will al...

Embodiment 3

[0066] Embodiment 3: An open-close fastening nut, the only difference from Embodiments 1 and 2 is that the passive part is a lead screw assembly containing a motor, and the active part is a slider threadedly connected to the screw rod. When the motor starts, The lead screw turns and the slider slides along the lead screw.

[0067] The slider is fixedly connected with the first half nut, the lead screw assembly includes a lead screw and a base plate, the motor is fixed on the base plate, and the base plate and the second half nut are also fixedly connected by two or four connecting rods. As for the specific setting of the connecting rod, it is the same as that of Embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com