Manual-automatic integrated encoder precision detection device

An accuracy detection and encoder technology, applied in the direction of instruments, etc., can solve the problems that the photoelectric encoder accuracy automatic detection device cannot accurately determine the target angle, and is prone to errors, and achieves the effects of simple structure, low cost, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

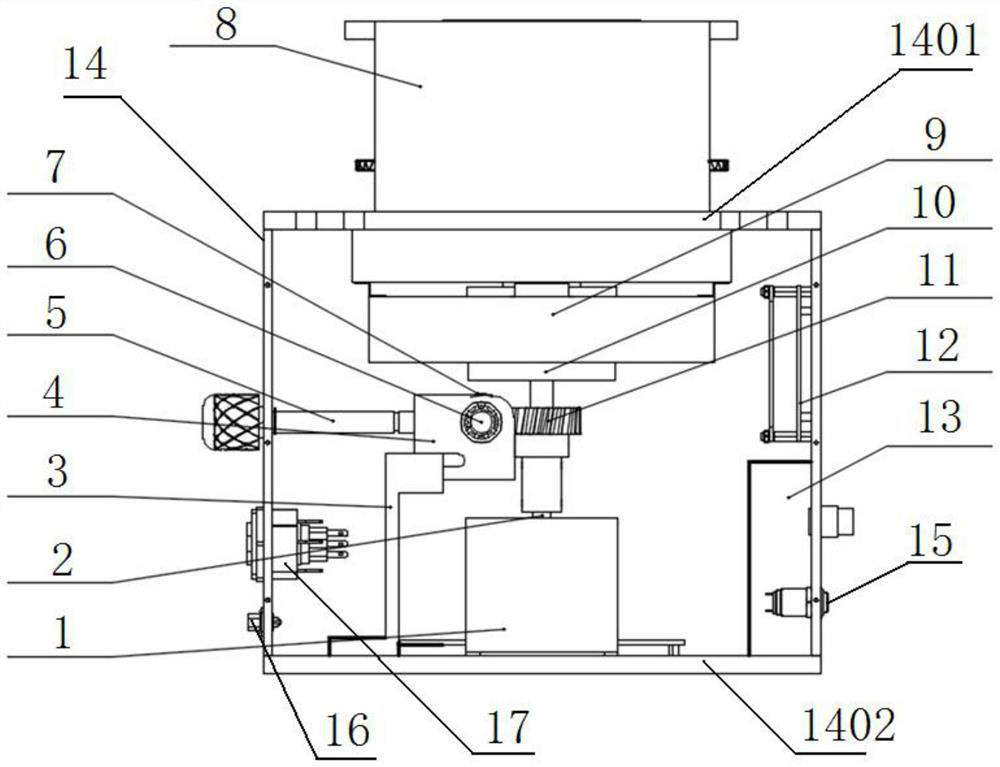

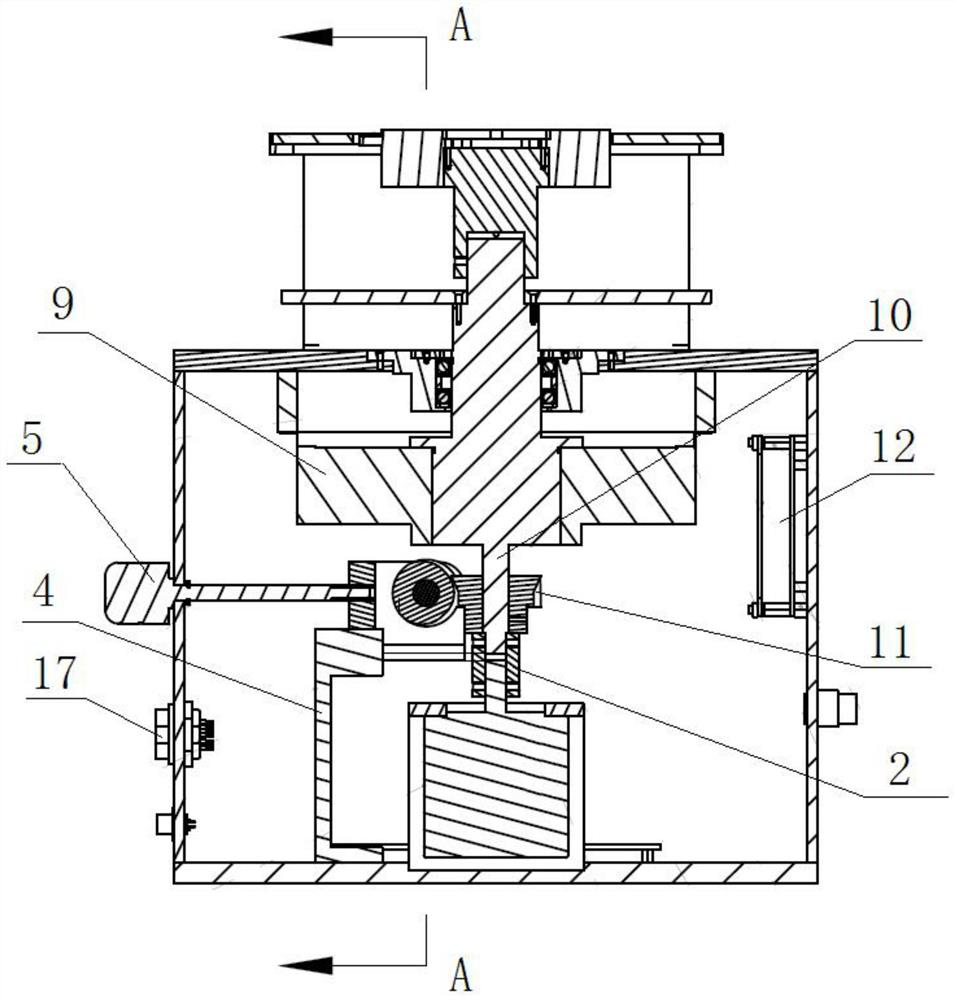

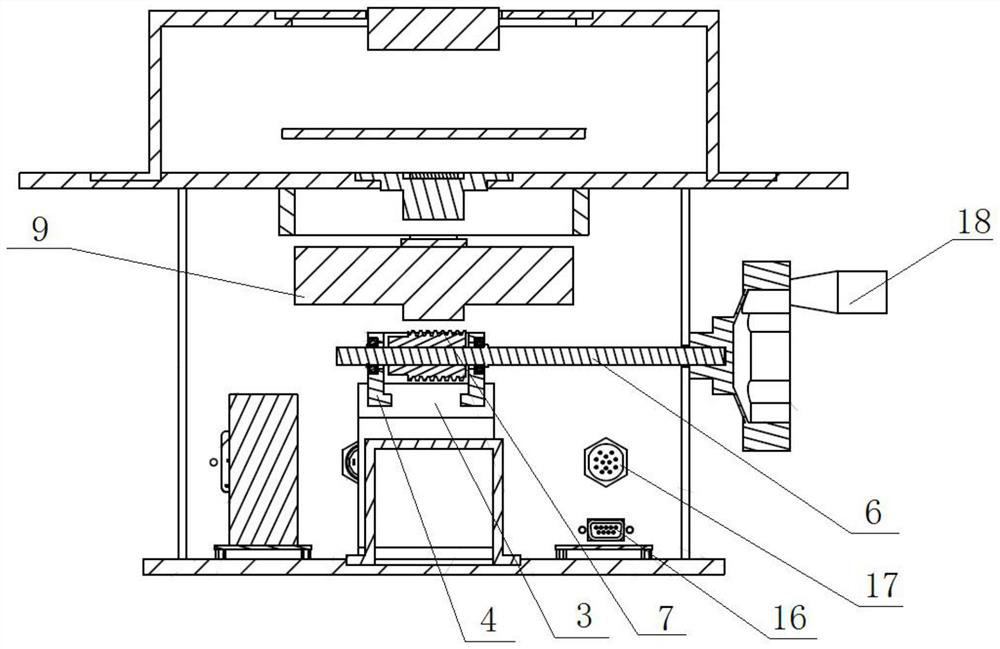

[0027] As shown in the figure, an automatic manual encoder accuracy detection device includes a stepping motor bracket 1, a stepping motor 2, a travel slide 3, a travel frame 4, a travel rod 5, a manual transmission rod 6, a worm 7, a support Frame 8, reference encoder 9, main shaft 10, turbine 11, display device 12, control device 13, base 14, main power switch 15, power socket 16 and stepper motor driver 17;

[0028] The base 14 includes an upper base 1401, a lower base 1402 and four panels connected between the upper base 1401 and the lower base 1402, the upper base 1401, the lower base 1402 and the four panels form a rectangular parallelepiped shell; A display device 12, a control device 13, a main power switch 15, a power socket 16 and a stepper motor driver 17 are fixedly installed on the panel;

[0029] The stepper motor support 1 is fixedly installed on the lower base 1402, and the stepper motor 2 is fixedly installed on the top of the stepper motor support 1; the outp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap