Ball valve sealing performance detection device and method capable of being judged through gas pressure intensity

A sealing performance and detection device technology, which is applied in fluid tightness testing, by measuring the rate of increase and deceleration of the fluid, and measurement devices, can solve the problems of increased labor costs and low detection efficiency, and achieve reduced use costs and simple operation Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

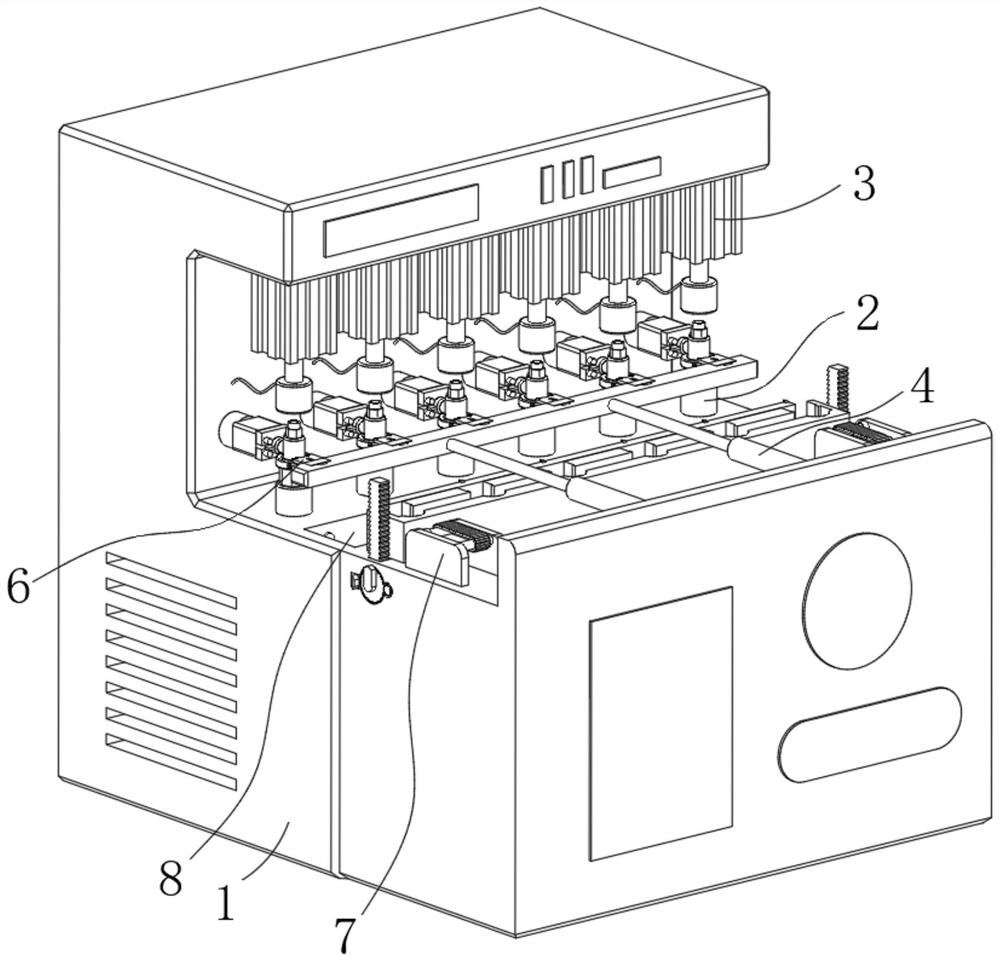

[0036] see Figure 1-Figure 4 , a ball valve sealing performance detection device that can be judged by gas pressure in the figure, including a body 1, a storage device 7 and a feeding device 8, and the body 1 is provided with multiple sets of detection seats 2 and lifting and inflation detection equipment 3 , the body 1 is fixedly connected with a telescopic rod 4, and the telescopic end of the telescopic rod 4 is fixedly connected with a push-pull rod 5, and the push-pull rod 5 is provided with multiple groups of grabbing devices 6 for grabbing ball valves, so The storage device 7 is installed on the body 1 for storing a large number of ball valves to be detected, and when the telescopic rod 4 stretches once, a row of ball valves to be detected is pushed out in linkage for the grasping device 6 to grasp. The unloading device 8 is installed on the body 1, and is used to unload the ball valves that have been tested, and store qualified products and unqualified products separat...

Embodiment 2

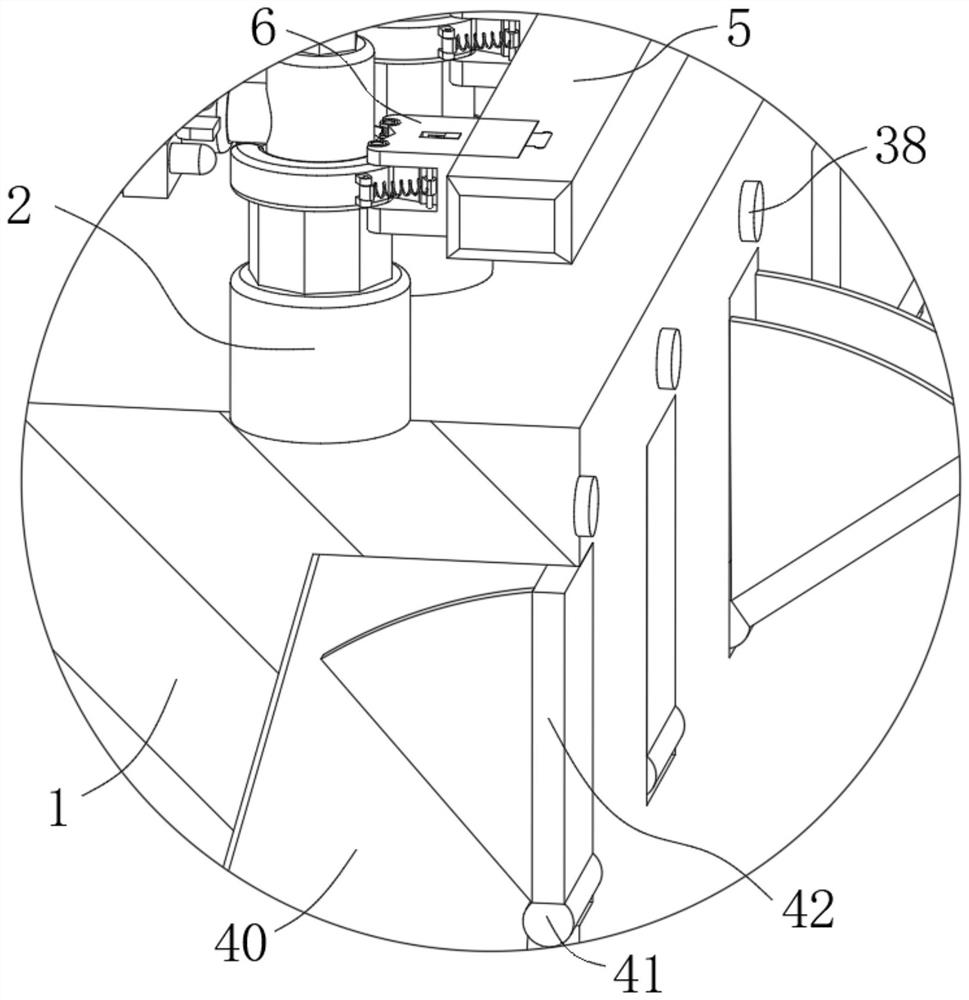

[0042] see Figure 5-Figure 7 and Figure 12 Embodiment 2 is illustrated. This embodiment further illustrates Embodiment 1. The unloading device 8 in the illustration includes a clockwork rotating shaft 30 installed on the body 1, and a baffle plate is fixedly connected to the clockwork rotating shaft 30. 31, the baffle plate 31 is fixedly connected with a triangular block 32, the bottom surface of the fixed plate 26 is fixedly connected with a fifth spring 33, the fixed plate 26 is slidably connected with a connecting rod 34, and the connecting rod 34 is fixed A lifting plate 35 fixedly connected with the fifth spring 33 is connected, the bottom surface of the lifting plate 35 is provided with a first slope 36 slidingly connected to the side of the triangular block 32, and the body 1 is provided with a A storage device 37 for depositing qualified products and non-qualified products.

[0043] see Figure 2-Figure 4 , the storage device 37 in the illustration includes a plur...

Embodiment 3

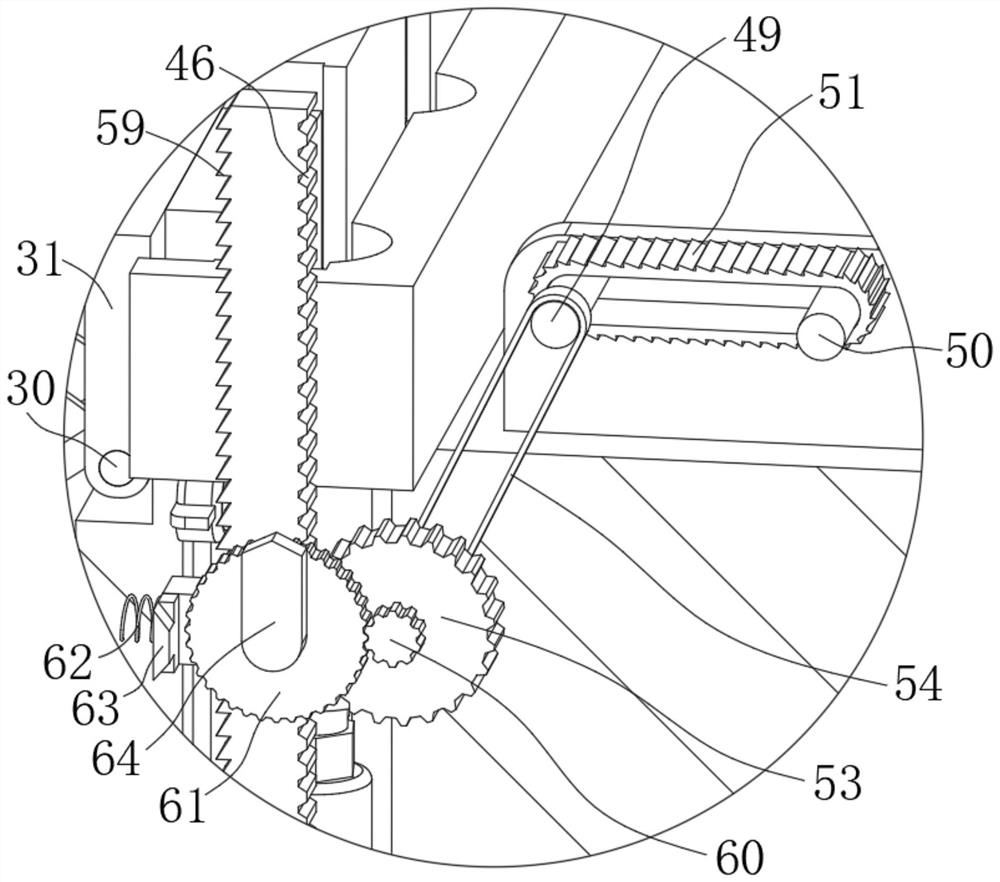

[0046] see Figure 5-Figure 9 Embodiment 3 is described. This embodiment further describes Embodiment 1. The storage device 7 in the illustration includes a lifting plate 43, and a plurality of storage tanks 44 are opened in the body 1. The top view shape of the storage tanks 44 is Consistent with the shape of the top view of the ball valve, a pushing groove 45 is opened in the body 1, and the lifting plate 43 is slidably connected with the pushing groove 45, and both ends of the lifting plate 43 are fixedly connected with the pushing groove. 45 is slidably connected to the first rack 46. The body 1 is provided with a discharge trough 47 for ball valve discharge. The rack 46 moves up the linkage 48 of the set distance.

[0047] see Figure 2-Figure 10 , the linkage 48 in the illustration includes a second rotating shaft 49 and a third rotating shaft 50 that are rotationally connected with the body 1, and both the second rotating shaft 49 and the third rotating shaft 50 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com