Vertical MEMS (Micro Electro Mechanical System) bent probe inserting device and method

A pin insertion device and vertical technology, applied in the field of semiconductor chip testing, can solve the problems of pin position offset, spillage, bending, etc., and achieve the effect of low cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

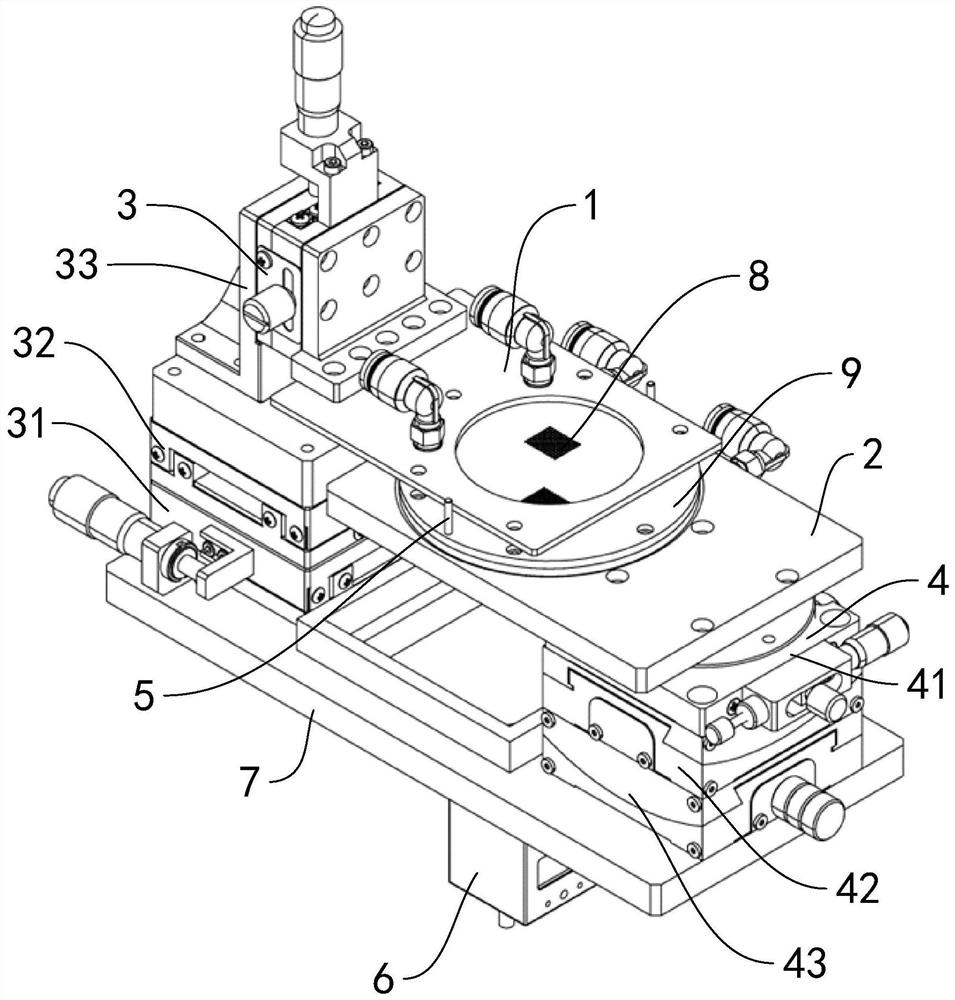

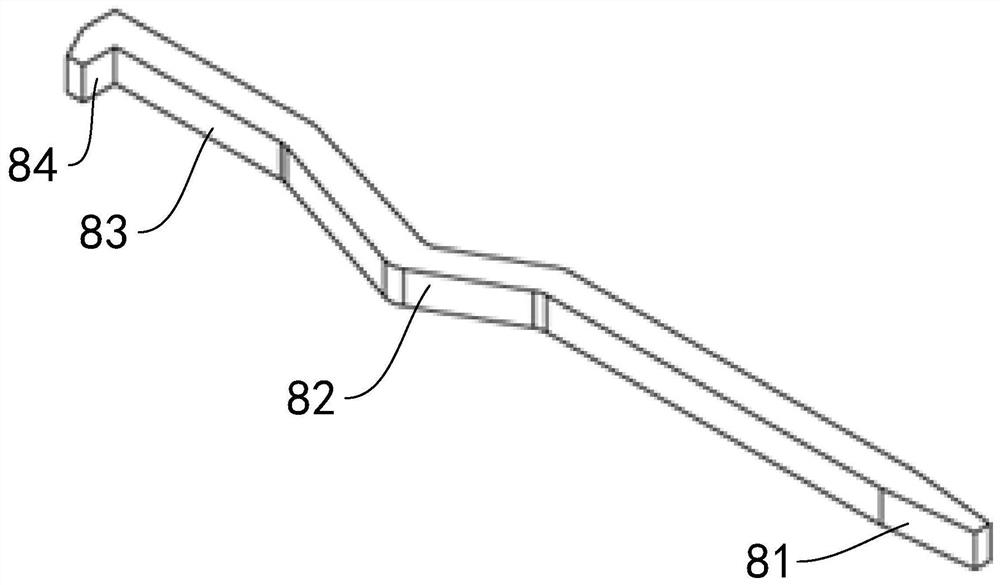

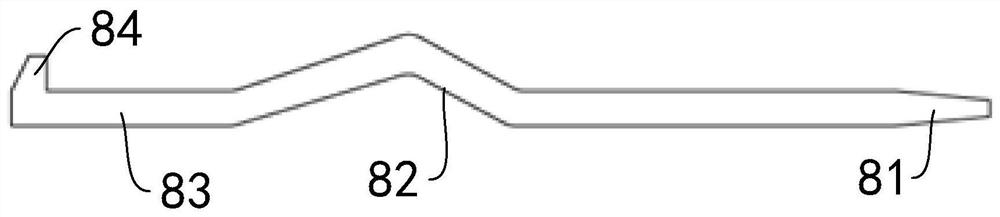

[0090] Reference attached figure 1 to the attached Figure 12As shown, the first embodiment of the present invention proposes a vertical MEMS curved probe pin insertion device for inserting the vertical MEMS curved probe into the probe card 9, the probe has a needle tip 81, a needle belly 82. Needle tail 83 and needle hook 84, the needle belly 82 of the probe is a curved structure, the central axis extension line of the needle tip 81 and the central axis extension line of the needle tail 83 are parallel, the probe card 9 includes an upper cover plate 91 and a lower cover plate 92, the upper cover plate 91 is provided with an upper probe hole 911 for the needle tail 83 to pass through, and the lower cover plate 92 is provided with a lower probe hole for the needle tip 81 to pass through. The probe hole 921 is characterized in that the cross section of the lower probe hole 921 is larger than that of the upper probe hole 911, and the pin insertion device includes: an upper fixi...

Embodiment 2

[0133] Embodiment 2, refer to the attached Figure 13 to the attached Figure 15 As shown, the second embodiment of the present invention proposes a method for inserting a Cobra probe. The method is implemented using the device described in the first embodiment, and the method includes the following steps:

[0134] Step 1: Pin Preparation

[0135] 1. The first mobile station 311 moves to a safe position;

[0136] 2. The second mobile station 321 moves to a safe position;

[0137] 3. The third mobile platform 331 ascends and moves to a safe position;

[0138] 4. The first tilt table 411 is moved to a safe position;

[0139] 5. The second tilt table 421 is moved to a safe position;

[0140] 6. The third tilt table 431 is moved to a safe position;

[0141] 7. The vacuuming air circuit of the upper fixing plate 11 is closed, and it is in a normal air pressure state;

[0142] 8. The vacuuming air circuit of the lower fixing plate 21 is closed, and it is in a normal air press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com