Optical prism film for small-size backlight module

A technology of backlight module and prism film, which is applied in the direction of optics, prisms, optical components, etc., can solve the problems of poor performance of prism film, poor astigmatism effect of prism film, and inability to install prism film, etc., to achieve long service life and increase reflection Light-splitting performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

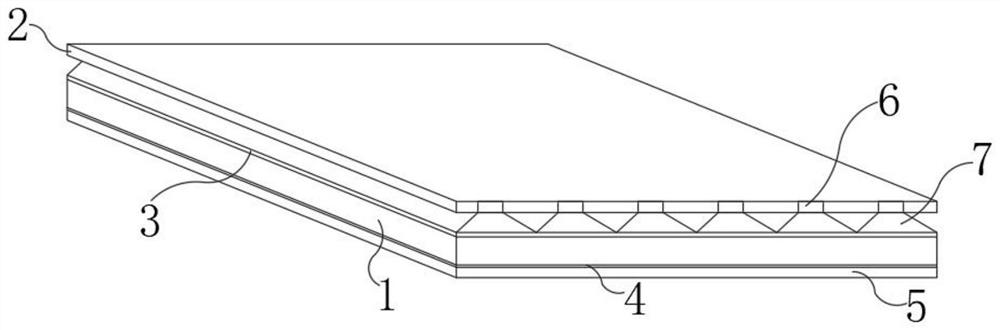

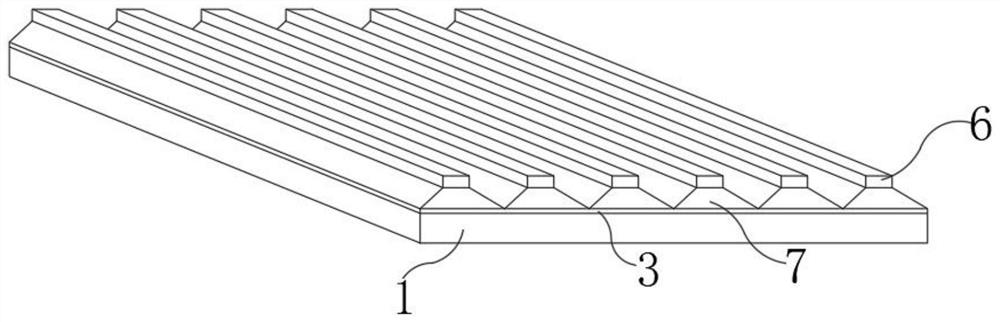

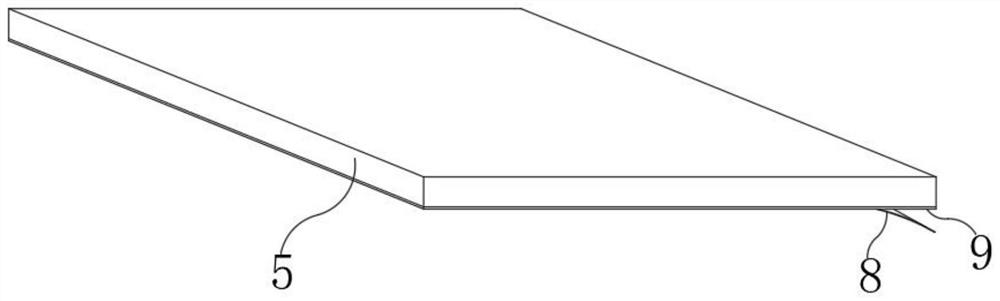

[0028] Such as Figure 1-5 As shown, an optical prism film for a small-sized backlight module includes a prism film main body 1, a prism structure 7 is fixedly connected to the outer surface of the upper end of the prism film main body 1, and a prism structure 7 is fixedly connected between the prism film main body 1 and the prism structure 7 No. OCA glue 3, the lower end of the prism film main body 1 is fixedly connected with the lower protective film 5, the lower protective film 5 is fixedly connected between the prism film main body 1 and the lower protective film 5, and the upper end of the prism structure 7 is fixedly connected with the upper protective film 2 A structural protective frame 6 is arranged between the prism structure 7 and the upper protective film 2, the lower end of the lower protective film 5 is fixedly connected with an adhesive mounting layer 9, and the lower end of the adhesive mounting layer 9 is provided with a tear film 8.

[0029] Further, the lowe...

Embodiment 2

[0033] On the basis of Example 1, as Figure 1-5As shown, an optical prism film for a small-sized backlight module includes a prism film main body 1, a prism structure 7 is fixedly connected to the outer surface of the upper end of the prism film main body 1, and a prism structure 7 is fixedly connected between the prism film main body 1 and the prism structure 7 No. OCA glue 3, the lower end of the prism film main body 1 is fixedly connected with the lower protective film 5, the lower protective film 5 is fixedly connected between the prism film main body 1 and the lower protective film 5, and the upper end of the prism structure 7 is fixedly connected with the upper protective film 2 A structural protective frame 6 is arranged between the prism structure 7 and the upper protective film 2, the lower end of the lower protective film 5 is fixedly connected with an adhesive mounting layer 9, and the lower end of the adhesive mounting layer 9 is provided with a tear film 8.

[00...

Embodiment 3

[0037] On the basis of embodiment one and embodiment two, such as Figure 1-5 As shown, an optical prism film for a small-sized backlight module includes a prism film main body 1, a prism structure 7 is fixedly connected to the outer surface of the upper end of the prism film main body 1, and a prism structure 7 is fixedly connected between the prism film main body 1 and the prism structure 7 No. OCA glue 3, the lower end of the prism film main body 1 is fixedly connected with the lower protective film 5, the lower protective film 5 is fixedly connected between the prism film main body 1 and the lower protective film 5, and the upper end of the prism structure 7 is fixedly connected with the upper protective film 2 A structural protective frame 6 is arranged between the prism structure 7 and the upper protective film 2, the lower end of the lower protective film 5 is fixedly connected with an adhesive mounting layer 9, and the lower end of the adhesive mounting layer 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com