Processing box

A processing box and box body technology, which is applied in the field of processing boxes, can solve the problems of time-consuming, structural interference, difficulty in power receiving unit and driving unit, etc., so as to improve work efficiency, smooth contact and meshing process, and save contact and meshing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

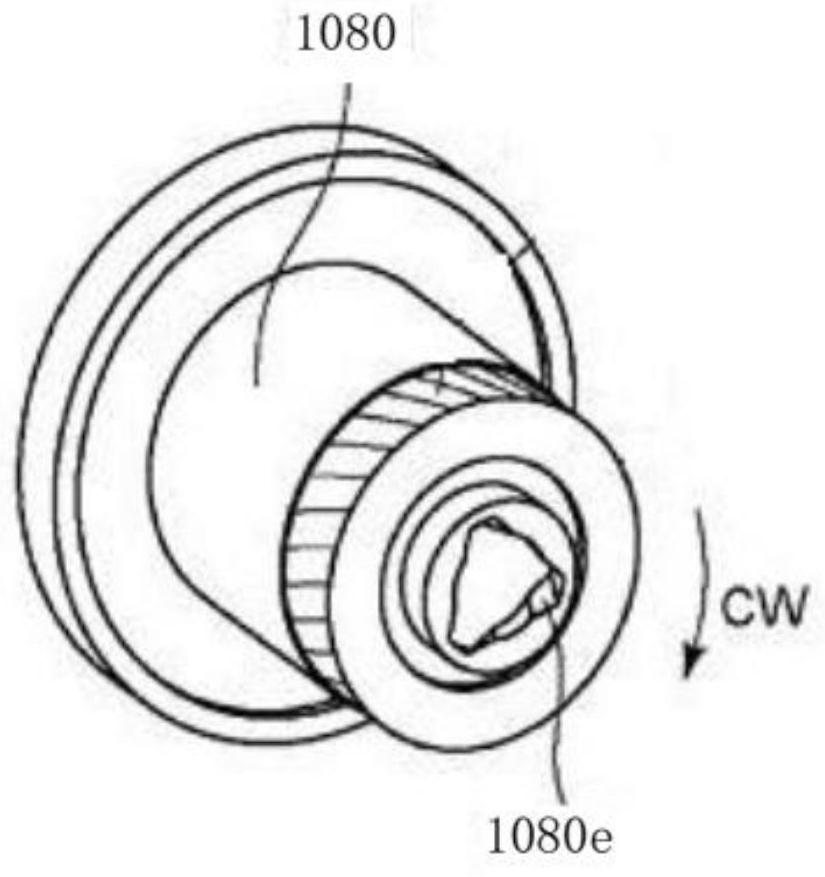

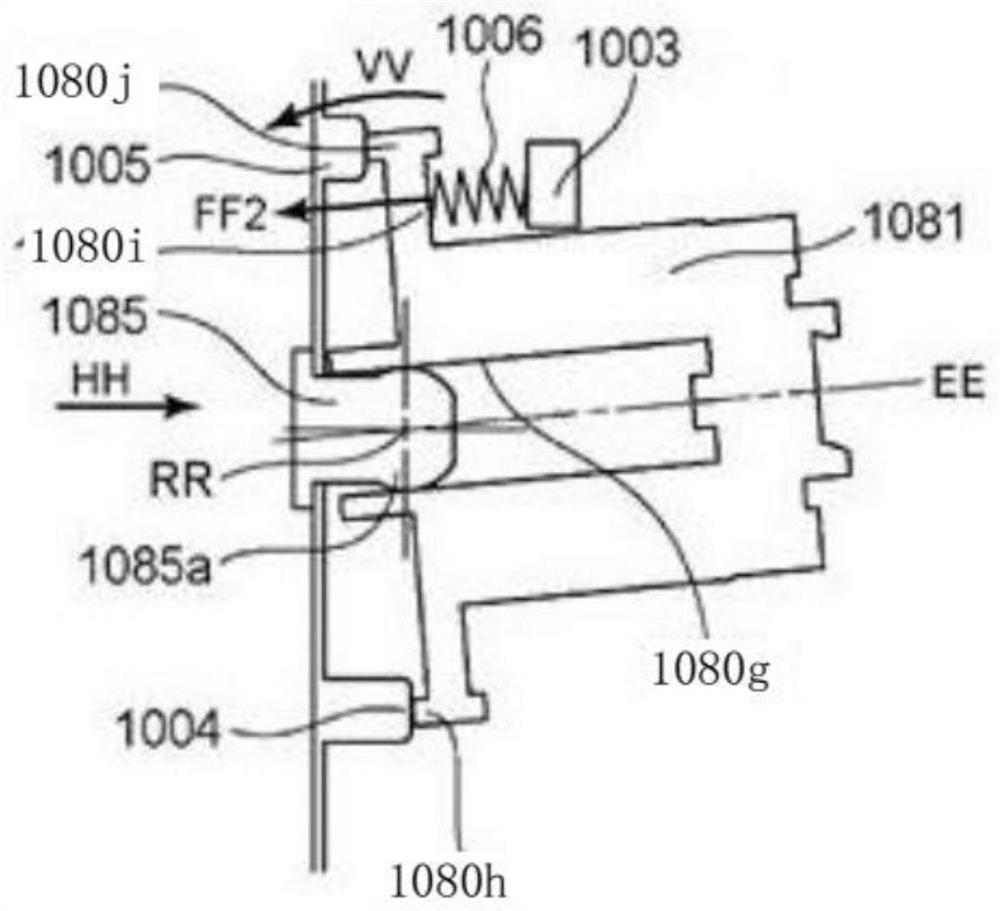

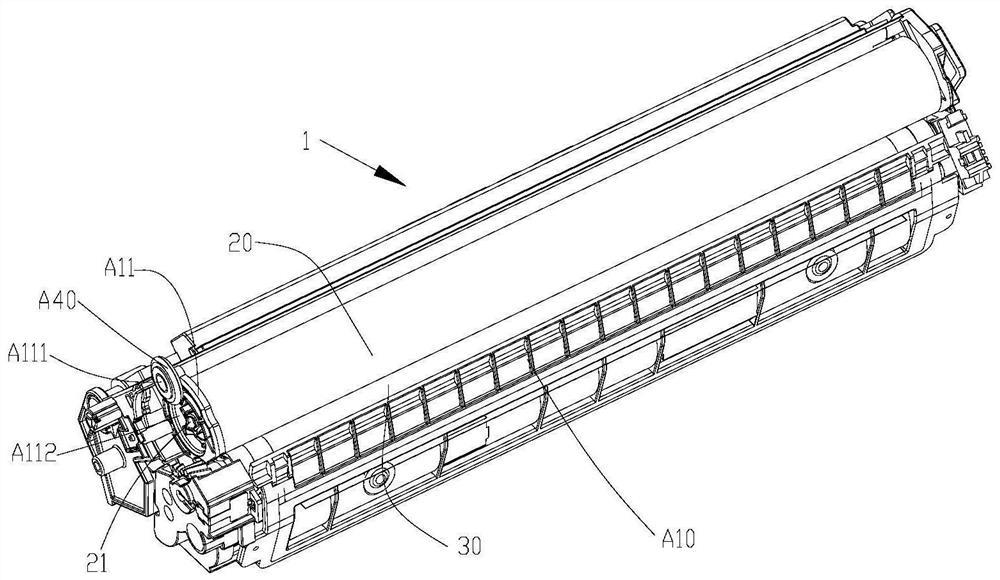

[0300] An embodiment of the present application provides an electronic imaging device, which includes a process box 1 , a driving unit 1080 and a driving unit protective cover 1081 , and the driving unit protective cover 1081 is disposed outside the driving unit 1080 .

[0301] The electronic imaging device may be a printer, a copier, an all-in-one scanning and copying machine, etc., which is not limited here. The following uses a printer as an example to describe the solution. The process cartridge may be a toner cartridge, an ink cartridge, or the like.

[0302]The processing box is generally composed of a toner bin unit and a waste toner bin unit. The toner bin unit includes a developing roller, a powder outlet knife, a powder feeding roller and a stirring frame, etc., and the waste toner bin unit includes a photosensitive drum, a charging roller, and a cleaning blade, etc. . The process box usually also includes a developer, and a power receiving unit for receiving exter...

Embodiment 2

[0310] Another process cartridge is provided in this embodiment, and the unspecified parts are the same in structure as the process cartridge in the first embodiment.

[0311] Such as Figure 7 and Figure 8 As shown, the process box 1 also includes a movable positioning member B50, which is movably arranged on the bracket B11 and located at the same end as the power receiving unit 21, and the positioning member B50 can be displaced in a first direction relative to the bracket B11, Wherein, the first direction is the height extending direction of the process box ( Figure 8 in the Z direction). Further, the bracket B11 is provided with a sliding slot B15, which may be a rectangular sliding slot or a circular sliding slot, or other regular or irregular sliding slots, which are not limited here. The positioning member B50 is slidably disposed on the chute B15, so that the locating member B50 can move along the chute B15 relative to the box body.

[0312] When the process box...

Embodiment 3

[0316] This embodiment provides another kind of pressing member, which is a further improvement on the basis of the second embodiment. The unexplained parts are the same as those in the foregoing embodiments, and will not be repeated for brevity.

[0317] Such as Figure 9 and Figure 10 As shown, the process box 1 also includes a movable positioning piece C50 and an elastic stretching piece C60. The positioning piece C50 is arranged on the bracket C11 and is located at the same end of the box body as the power receiving unit 21, and the positioning piece C50 is connected through the elastic stretching piece F60. The positioning member C50 is fixed to the bracket C11 so that it can move relative to the process cartridge body. The process box 1 also includes a pressing member C40, which is connected to the bracket C11 through a connecting rod C70. Specifically, the pressing member C40 is a gear, and the outer surface of the gear is a guiding pressing surface.

[0318] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com