A toroidal inductor automatic winding device

A ring-shaped inductor and automatic winding technology, which is applied in the manufacture of inductors, fixed inductors, inductors/transformers/magnets, etc., can solve the problems of long pause time, reduced winding efficiency, and low winding efficiency, and achieve action The effect of simplicity, quality improvement, and winding efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0056] Inductors, including skeleton and winding (enameled wire), etc., the skeleton is generally in the shape of a ring, and the enameled wire is wrapped around the skeleton.

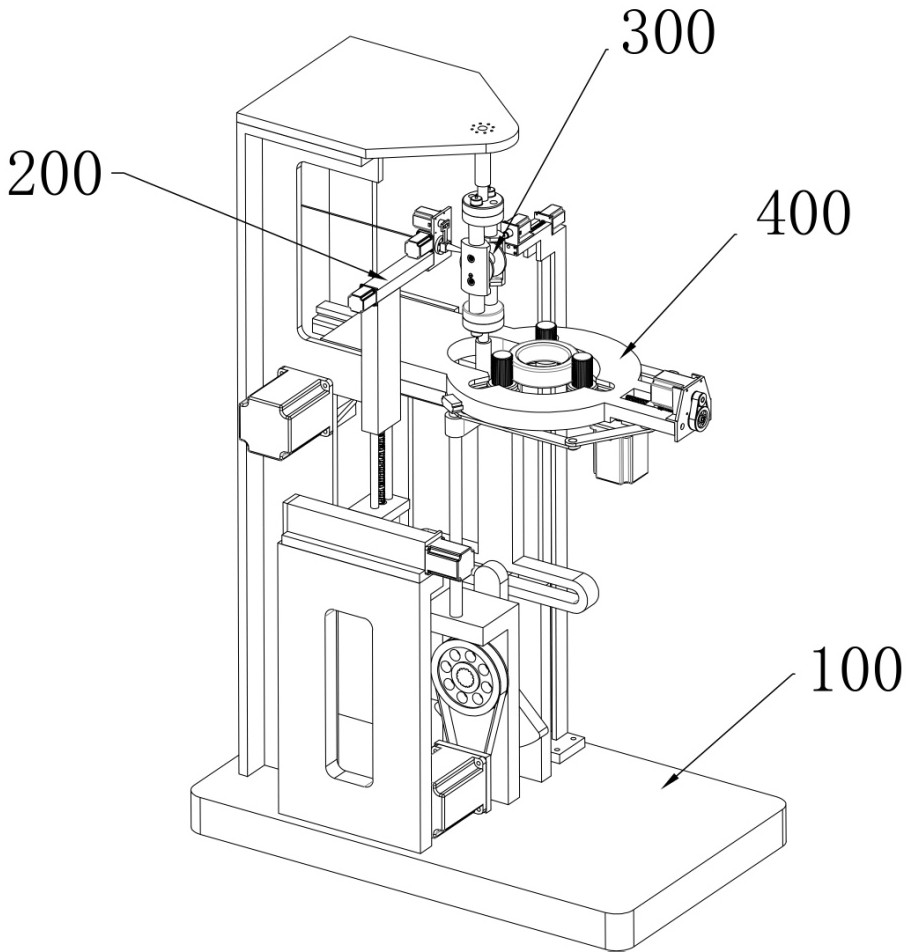

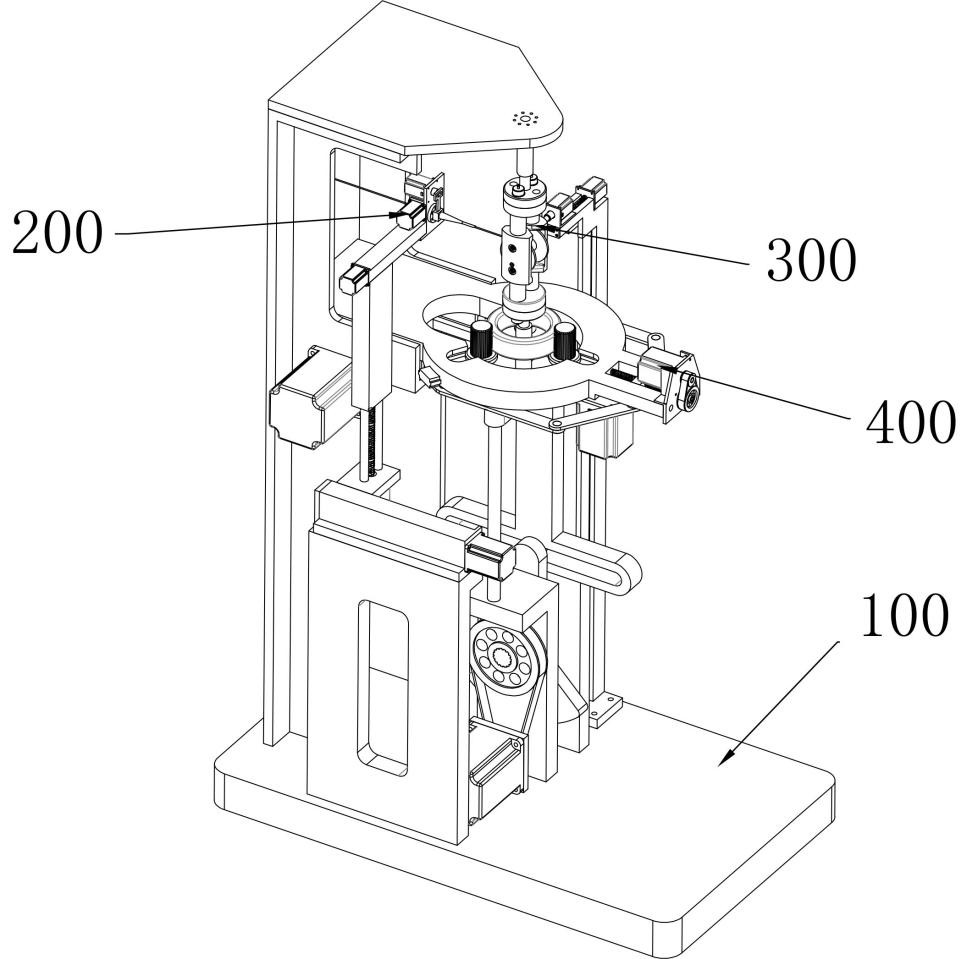

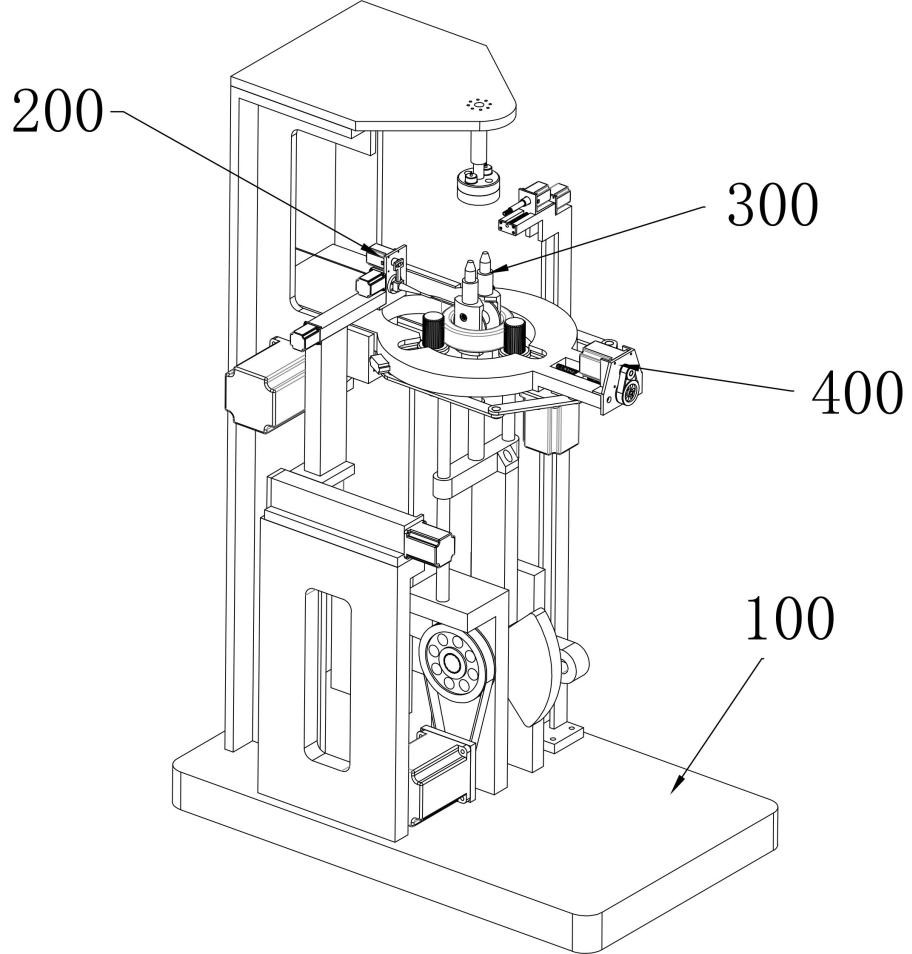

[0057] like Figure 1-7 As shown, an automatic winding device for a toroidal inductor includes a rack 100, and a wire feeding device 200, a wire winding device 300 and a clamping device 400 are installed on the frame 100, wherein the wire feeding device 200 is used for winding The device 300 conveys the enameled wire, the winding device 300 is used for orderly winding and storing the enameled wire and pulling the wound enameled wire to reciprocate up and down in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com