Axial reciprocating translation motor

A translational and axial technology used in electromechanical devices, electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

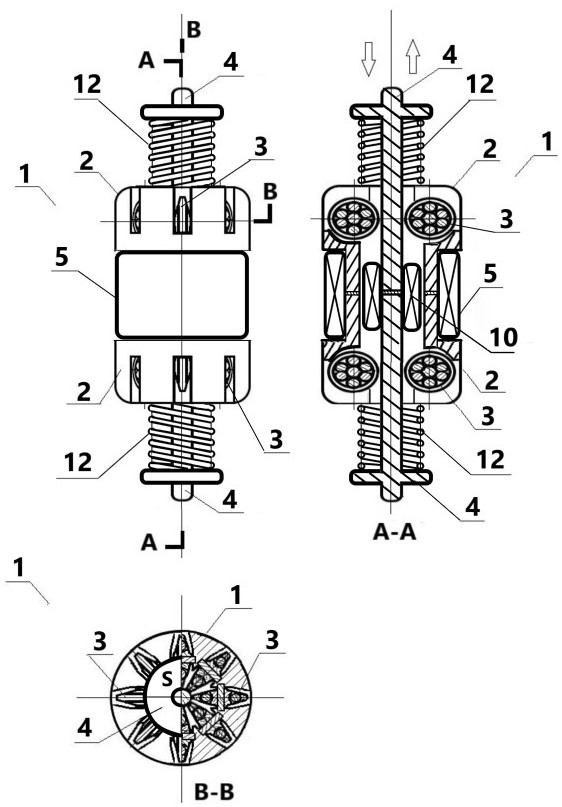

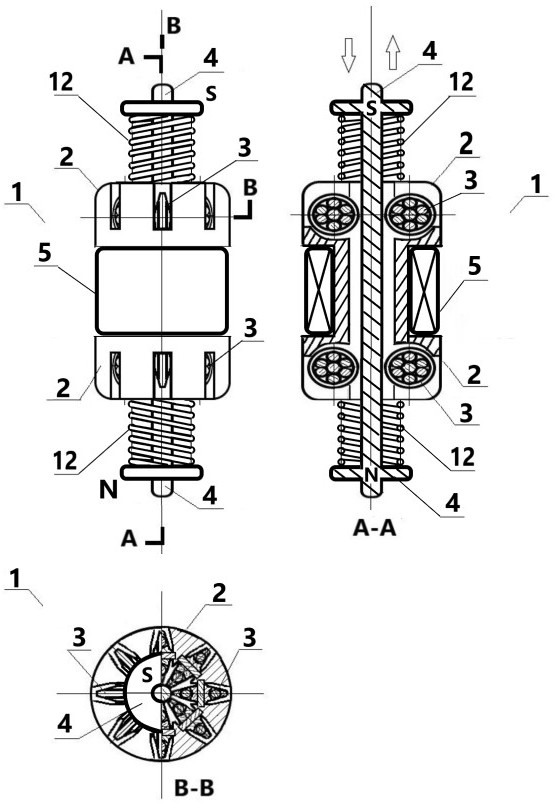

[0016] as attached figure 1 Shown is a three-view cross-sectional view of the first specific embodiment of the present invention-a cylindrical electromagnetic inner core axially reciprocating translational motor.

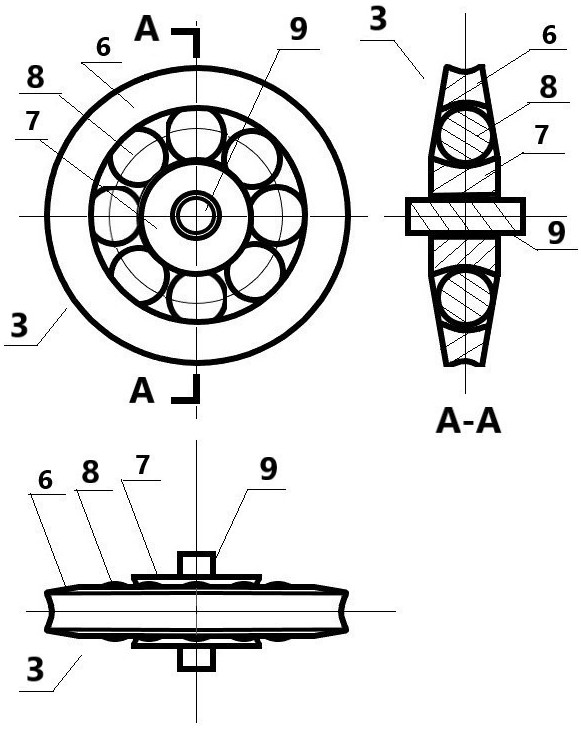

[0017] An axial reciprocating and translational motor, comprising a cylindrical shell 1, an axial telescopic bearing 2 is arranged at both ends of the shell 1, a plurality of inner roller bearings 3 are arranged in the axial telescopic bearing 2, and a plurality of inner roller bearings 3 Surrounding the translation inner core 4 symmetrically, the translation inner core 4 is constrained radially, and only the translation inner core 4 is allowed to reciprocate and translate in the axial direction. The motor casing 1 forms an axially telescopic combined bearing structure as a whole, so that the constraint of the motor casing 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com