Bar sticking plate for slicing machine

A slicer and stick stick technology, which is applied in the manufacture of tools, fine working devices, working accessories, etc., can solve the problems of diamond wire wear, long cutting time of the knife, etc., to reduce the probability of wear, high cutting efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

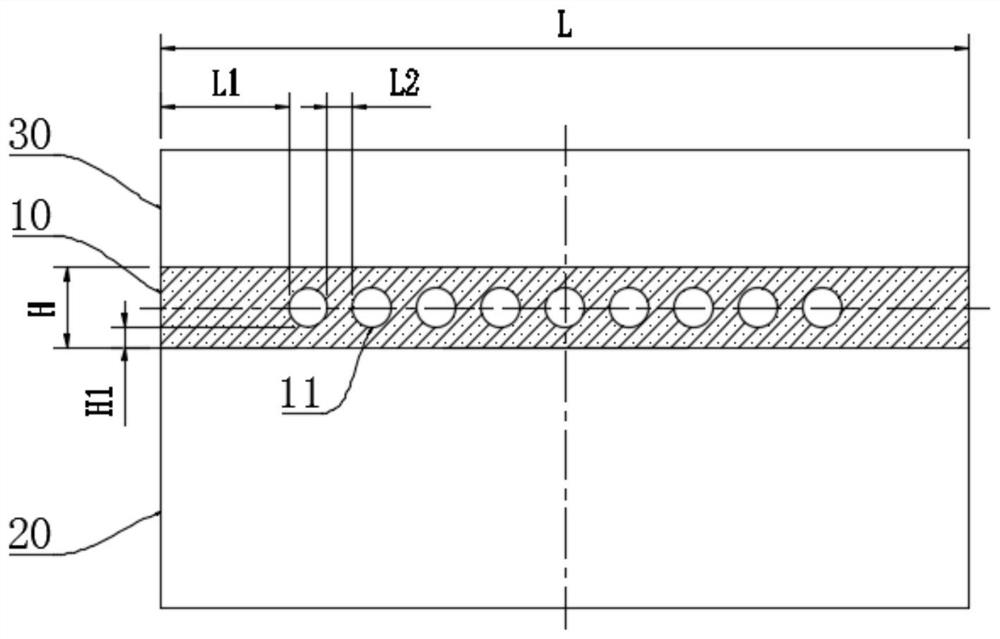

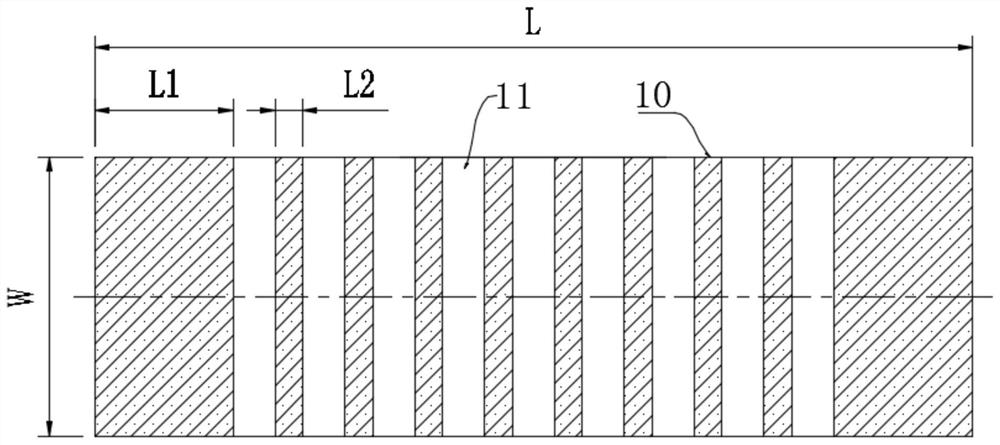

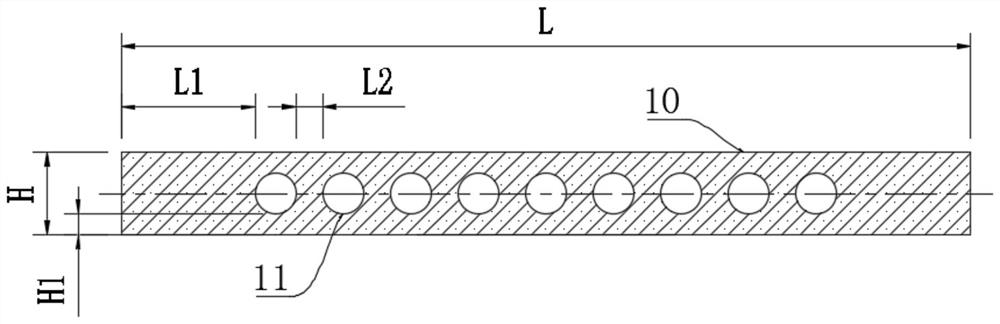

[0030] This embodiment proposes a sticky stick plate 10 for a slicer, and its matching structure with the silicon stick 20 and the material seat 30 is as follows: figure 1 As shown, in the slicer, a silicon rod 20 is bonded to one side of the sticky plate 10, and a material seat 30 is bonded to the other side opposite to the silicon rod 20, that is, the sticky plate 10 is bonded on the material seat 30 first. , and then bonded with the silicon rod 20, and then unifiedly installed in the installation compartment in the slicer after the final integral bonding, and make the side of the silicon rod 20 away from the sticking plate 10 face down and face the diamond wire The mesh is set, and the diamond wire mesh crosses the silicon rod 20 side by side and cuts the silicon rod 20 into several silicon wafers. In this embodiment, the sticky stick boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com