Ultraviolet-cured conductive silver adhesive and preparation method thereof

A technology of conductive silver glue and ultraviolet light, which is applied in the field of conductive glue, can solve the problems of limited application range of curing methods and insufficient long-term stability of conductive silver glue, and achieve excellent pollution resistance, simple operation steps, and high bonding strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

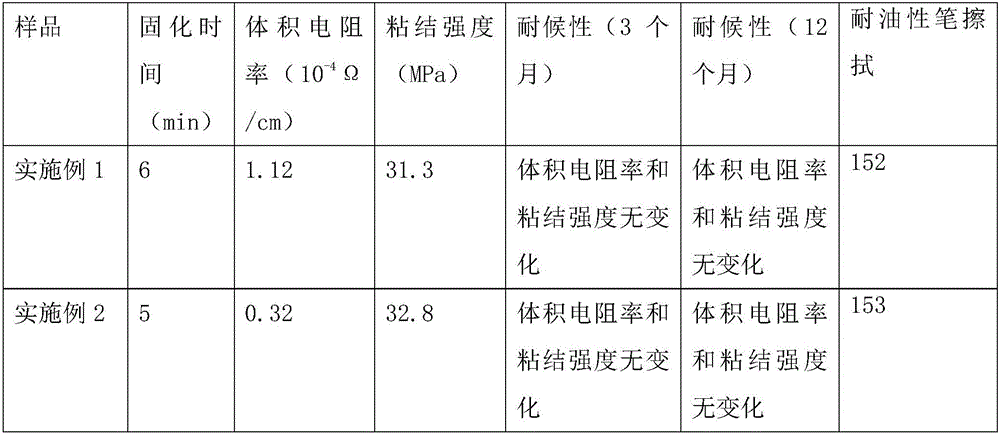

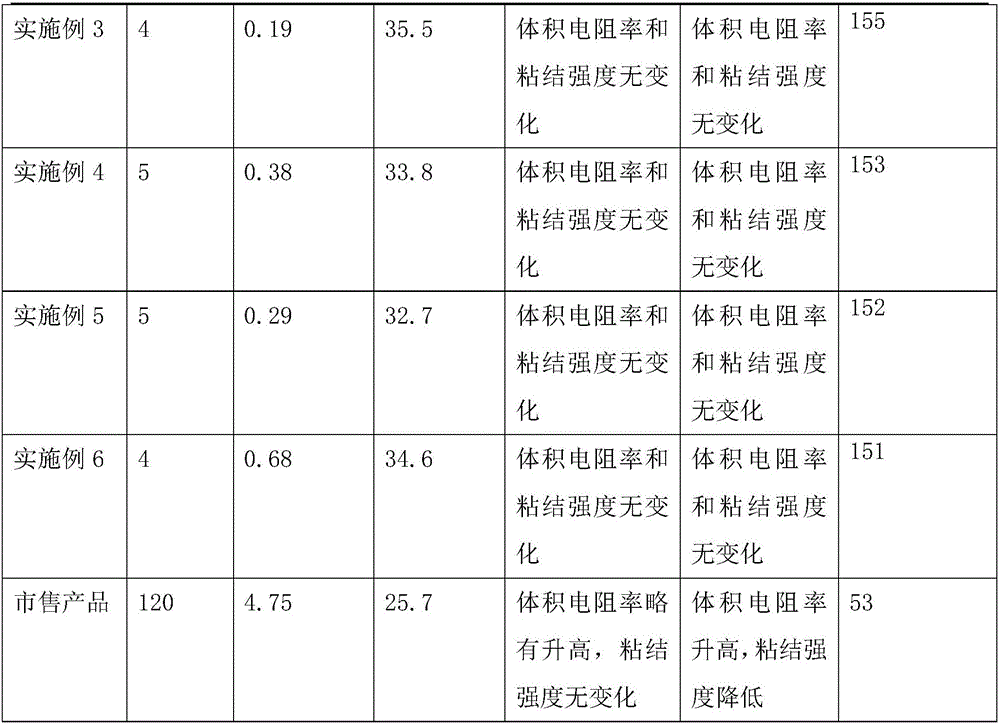

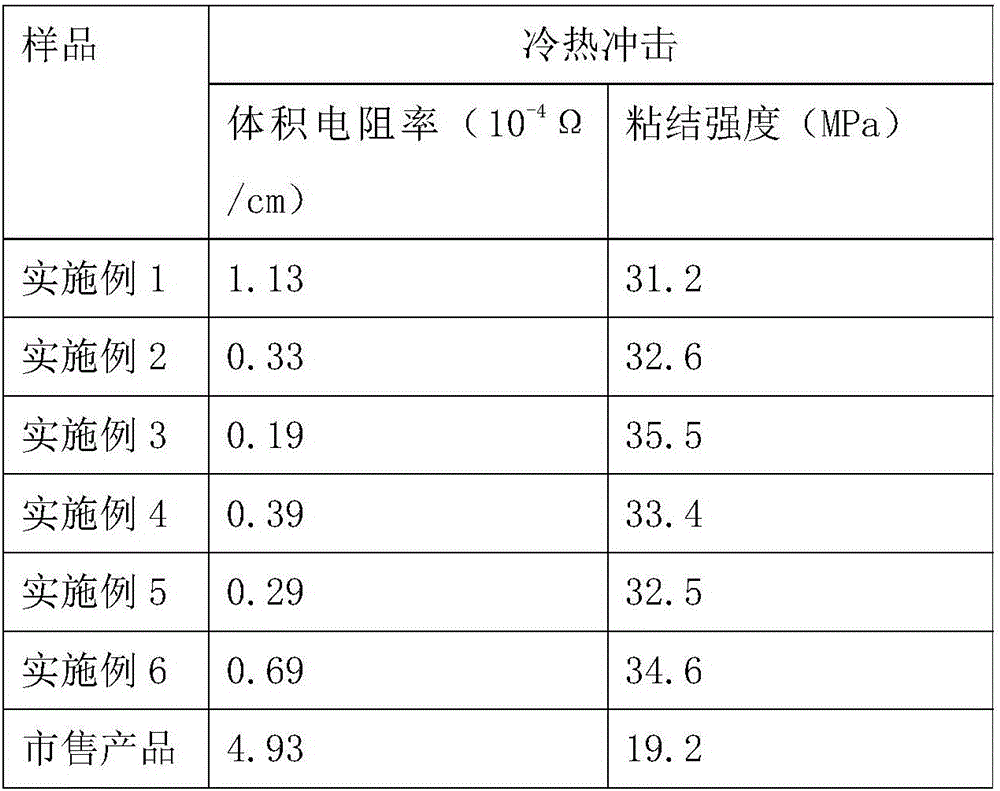

Examples

Embodiment 1

[0016] An ultraviolet light-curable conductive silver glue is prepared from the following components in parts by weight: 50 parts of base resin, 38 parts of conductive filler, 30 parts of reactive diluent, 5 parts of photoinitiator, 10 parts of stabilizer, functional 11 parts of auxiliary agent, 3 parts of leveling agent, 1 part of conduction accelerator and 1 part of coupling agent. The base resin is polyacrylate modified polyurethane resin and bisphenol A epoxy resin in a mass ratio of 1:1; the conductive filler is nano silver powder with a particle size of 50nm. The curing agent is polyamide or trimellitic anhydride; the reactive diluent is furfuryl alcohol glycidyl ether; and the photoinitiator is α-hydroxyalkyl phenone. The stabilizer is a liquid rare earth stabilizer; the functional additives are pollution-resistant additives and salt-spray-resistant additives, the pollution-resistant additive is SRC-220, and the salt-spray-resistant additive is HALOX515. The leveling a...

Embodiment 2

[0018] An ultraviolet light-curable conductive silver glue is prepared from the following components in parts by weight: 60 parts of base resin, 45 parts of conductive filler, 40 parts of reactive diluent, 9 parts of photoinitiator, 13 parts of stabilizer, functional 15 parts of auxiliary agent, 7 parts of leveling agent, 5 parts of conduction accelerator and 5 parts of coupling agent. The base resin is polyacrylate modified polyurethane resin and bisphenol A epoxy resin with a mass ratio of 1:3; the conductive filler is nano silver powder with a particle size of 10nm. The curing agent is polyamide or trimellitic anhydride; the reactive diluent is ethylene glycol diglycidyl ether; and the photoinitiator is α-aminoalkyl phenone. The stabilizer is a liquid rare earth stabilizer; the functional additives are pollution-resistant additives and salt-spray-resistant additives, the pollution-resistant additive is SRC-220, and the salt-spray-resistant additive is HALOX515. The levelin...

Embodiment 3

[0020] An ultraviolet light-curable conductive silver glue is prepared from the following components in parts by weight: 52 parts of base resin, 39 parts of conductive filler, 36 parts of reactive diluent, 8 parts of photoinitiator, 12 parts of stabilizer, fluid 5 parts of leveling agent, 12 parts of functional auxiliary agent, 2 parts of conduction accelerator and 3 parts of coupling agent. The base resin is polyacrylate modified polyurethane resin and bisphenol A epoxy resin with a mass ratio of 1:2; the conductive filler is nano silver powder with a particle size of 25nm. The curing agent is polyamide or trimellitic anhydride; the reactive diluent is neopentyl glycol diglycidyl ether; and the photoinitiator is α-hydroxyalkyl phenone and α-aminoalkyl phenone. The stabilizer is a liquid rare earth stabilizer; the functional additives are pollution-resistant additives and salt-spray-resistant additives, the pollution-resistant additive is SRC-220, and the salt-spray-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com