Low-value waste plastic vacuum feeding system

A technology of vacuum feeding and waste plastics, which is applied in the directions of plastic recycling, transportation and packaging, loading/unloading, etc. It can solve the problems of poor pyrolysis effect of low-value waste plastics, achieve the effect of reducing blockage and improving pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

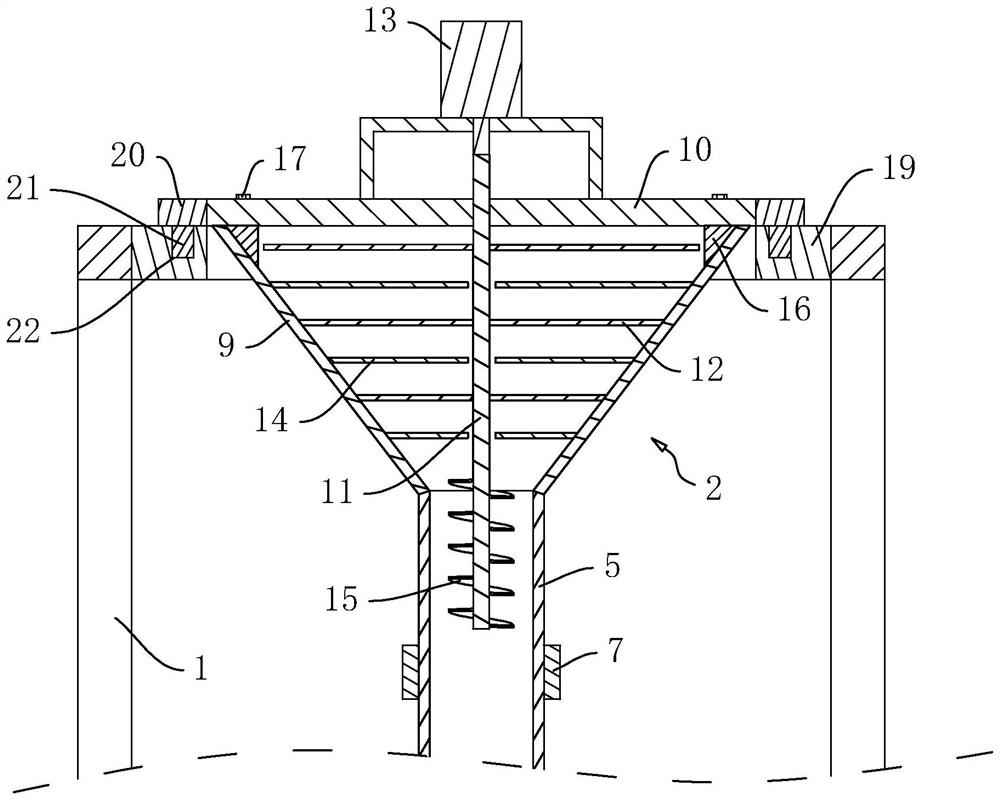

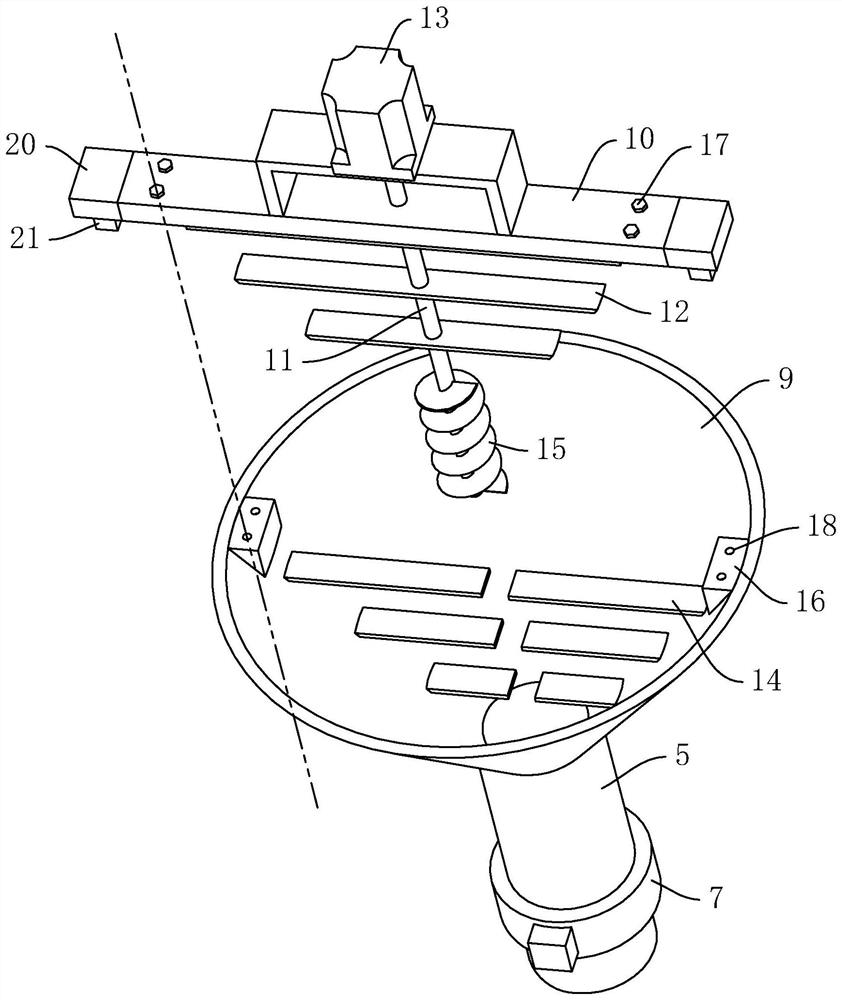

[0033] The following is attached Figure 1-4 The application is described in further detail.

[0034] The embodiment of the present application discloses a vacuum feeding system for low-value waste plastics.

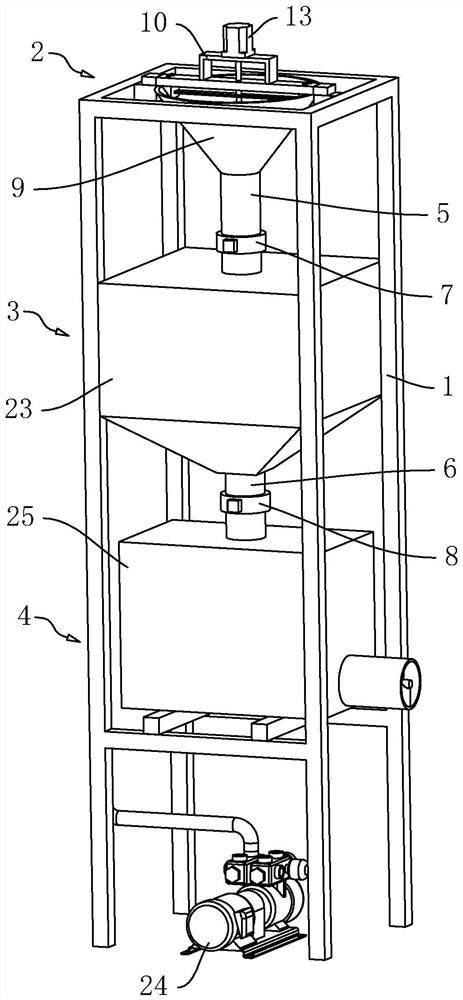

[0035] like figure 1 As shown, the vacuum feeding system for low-value waste plastics includes a bracket 1 erected between the quantitative feeder and the continuous pyrolyzer. The bracket 1 is arranged vertically from top to bottom for receiving the quantitative feeder. A storage device 2 for outputting materials, a vacuum device 3 for vacuumizing the materials, and a delivery device 4 for transporting the vacuumed materials to the continuous pyrolyzer; the feed port of the storage device 2 is located at The bottom of the output end of the quantitative feeder is used to receive the material output by the quantitative feeder. The discharge port of the storage device 2 is connected with the feed port of the vacuum device 3 through the first discharge pipe 5, and the dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap