Bolt fixing device for automobile manufacturing

A technology for automobile manufacturing and fixing devices, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems such as the inability to continuously and automatically supply bolts, etc., and achieve the effect of easy thread slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

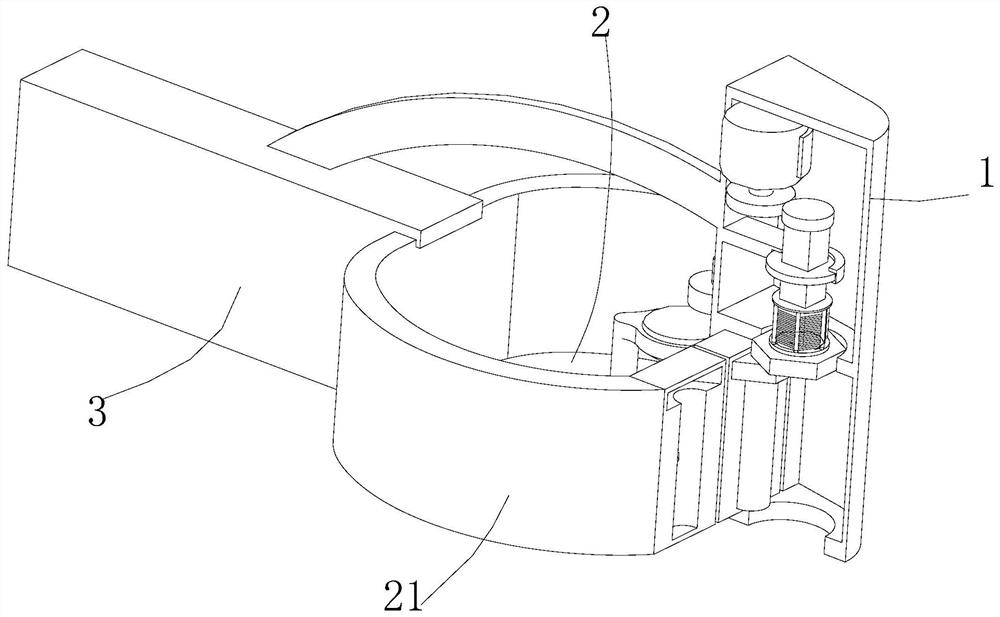

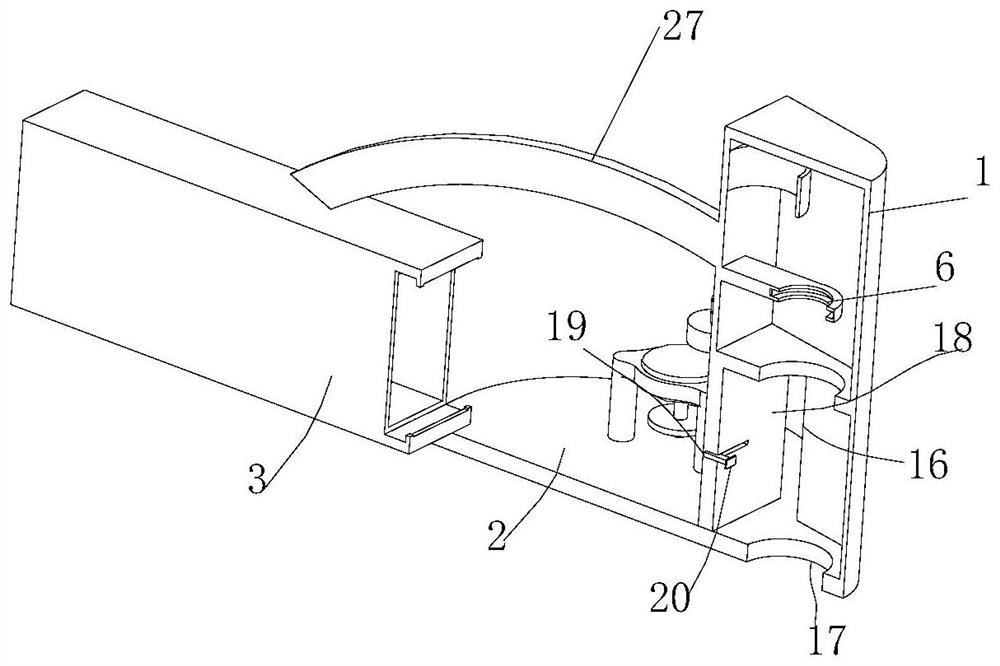

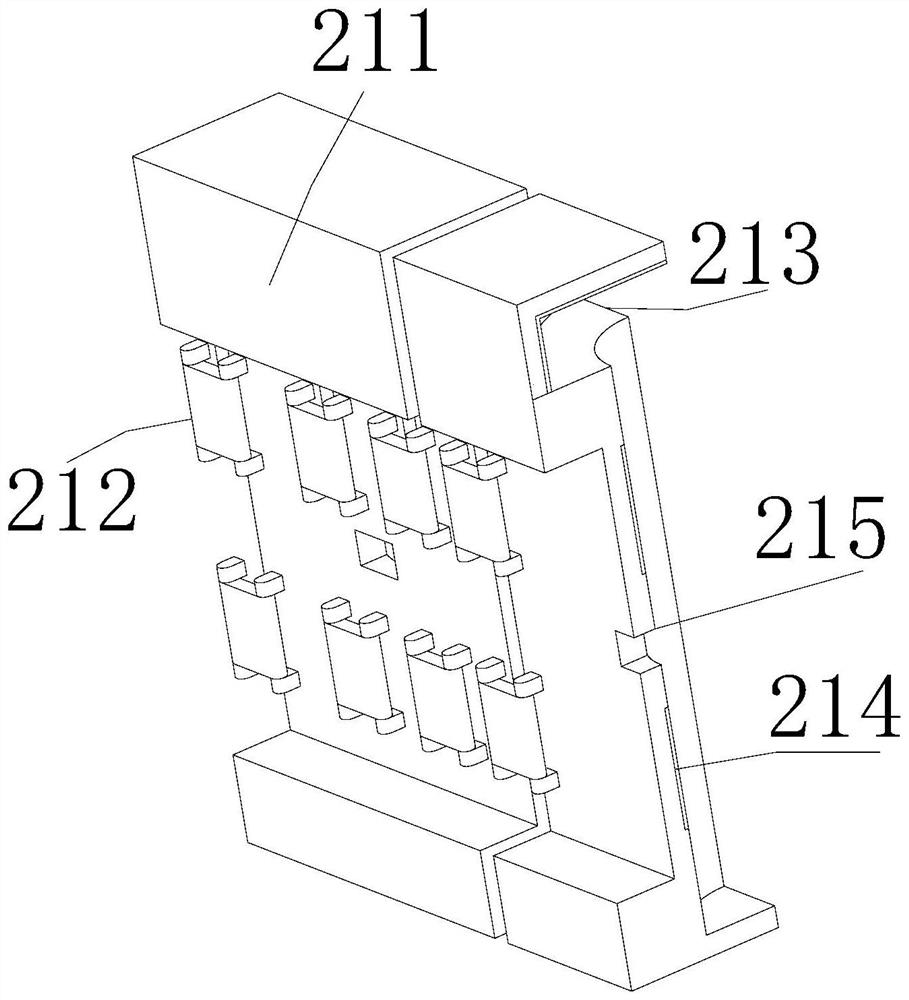

[0025] Embodiment one, such as Figure 1-7 As shown, it includes a housing 1, a bottom pallet 2 and a feeding box 3, the bottom pallet 2 is fixedly installed under the housing 1, the feeding box 3 is clamped on the rear end of the bottom pallet 2, and the outer surface of the housing 1 is rear A handle 27 is fixedly installed at the end, and the end of the handle 27 away from the housing 1 is clamped with the supply box 3. Through such an arrangement, the fixing device can be easily fixed, and at the same time, the supply box 3 can be easily replaced.

[0026] A motor 4 is fixedly installed inside the housing 1, and an active ratchet 5 is fixedly installed on the output end of the motor 4. A support sleeve 6 is fixedly installed inside the housing 1, and the rotation of the support sleeve 6 is connected with a rotating sleeve 7. The appearance of the rotating sleeve 7 A rotating plate 28 is fixedly installed, and the rotating plate 28 is rotatably connected to the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com