Offshore wind power barrel type foundation structure with pile piers

A basic structure and wind power tube technology, applied in the field of cylindrical basic structure, can solve the problems of increased wind power development cost and increased difficulty of entry into the soil, and achieve the effect of simple cylindrical basic structure, reduced development cost, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

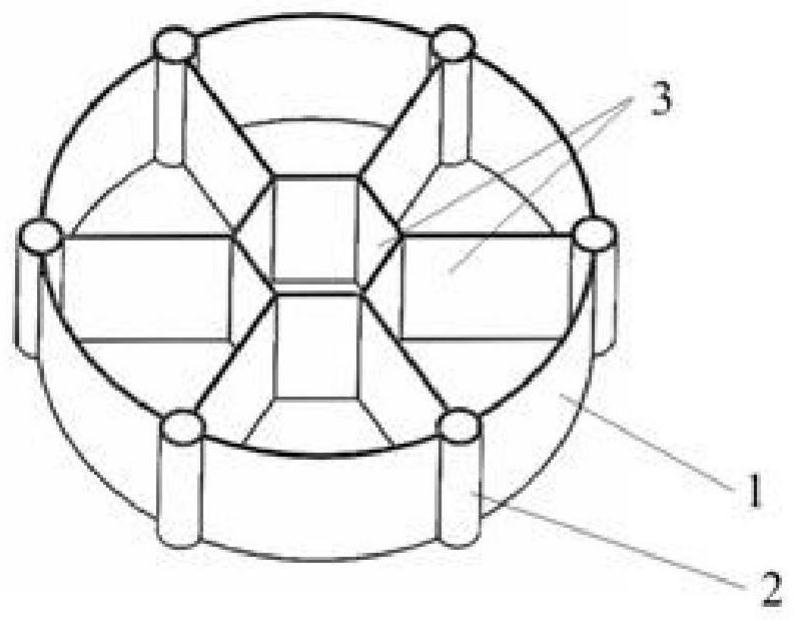

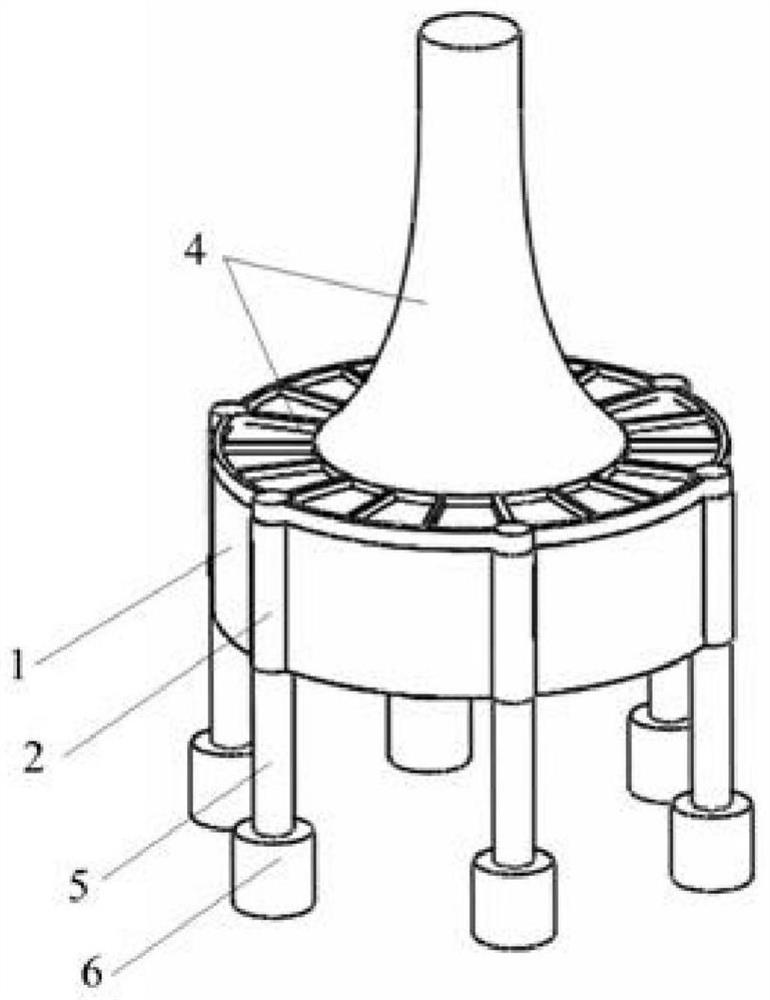

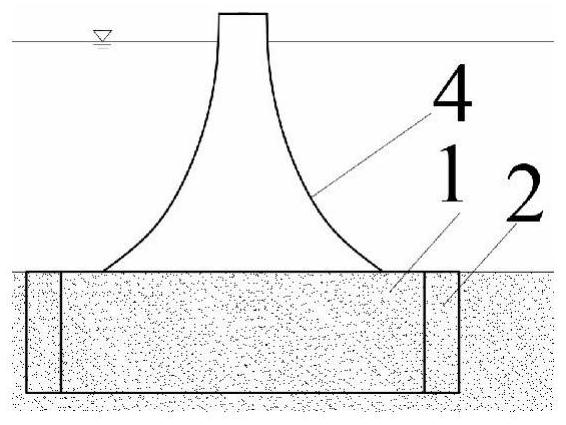

[0014] Such as Figure 1-2 As shown, an offshore wind turbine foundation structure with pile piers is composed of a tube skirt 1 , casing 2 , compartment plate 3 , superstructure 4 , steel piles 5 and cement piers 6 . The tube skirt 1 is cylindrical, with a height of 8m and a diameter of 30m. The arc surface of the cylinder is divided into six equal parts by six casings 2, and the inner diameter of the casing is 2m. 3. There are 12 sub-compartment plates in total, among which six sub-compartment plates form a regular hexagon, and the remaining six sub-compartment plates connect the six corners of the regular hexagon formed with the casing 2; The top of the tube skirt is provided with a superstructure 4, including a top cover, a transition section and a fan; the steel pile 5 is cylindrical, and there are six pieces in total, the length is set to 18m, and the outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com