Automatic die-casting production equipment for steering wheel framework of new energy automobile

A technology for new energy vehicles and production equipment, applied in the field of automatic die casting production equipment for steering wheel skeletons of new energy vehicles, to achieve the effects of reducing the influence of bonding, improving the demoulding efficiency, and cooling accurately and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

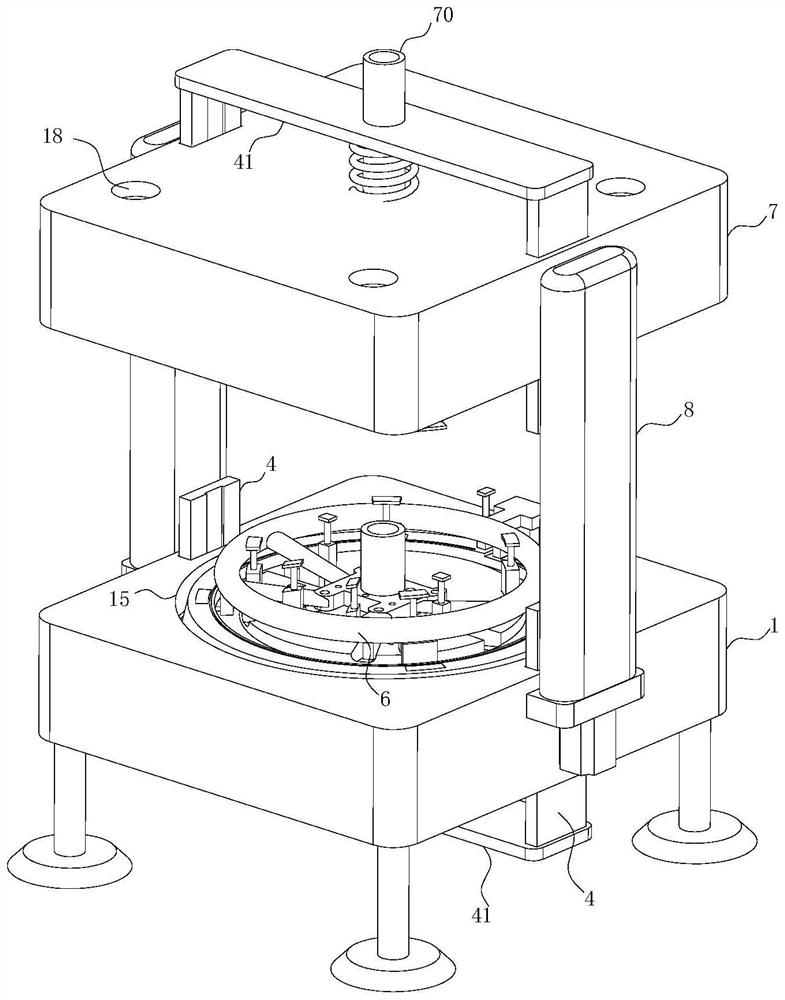

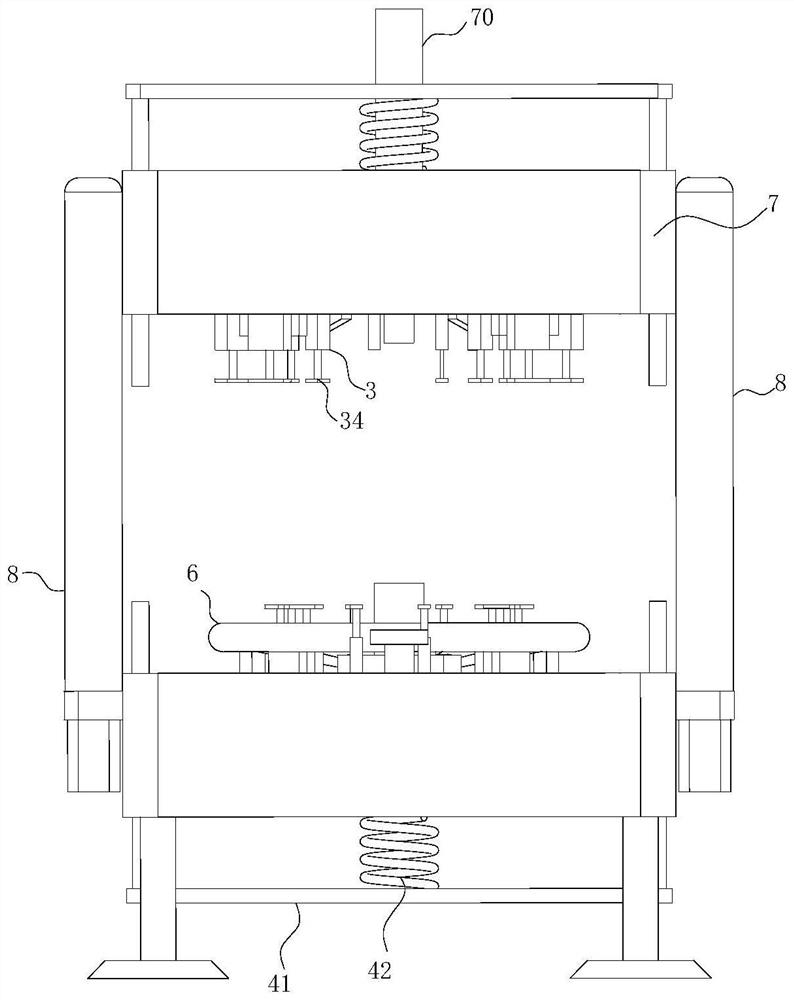

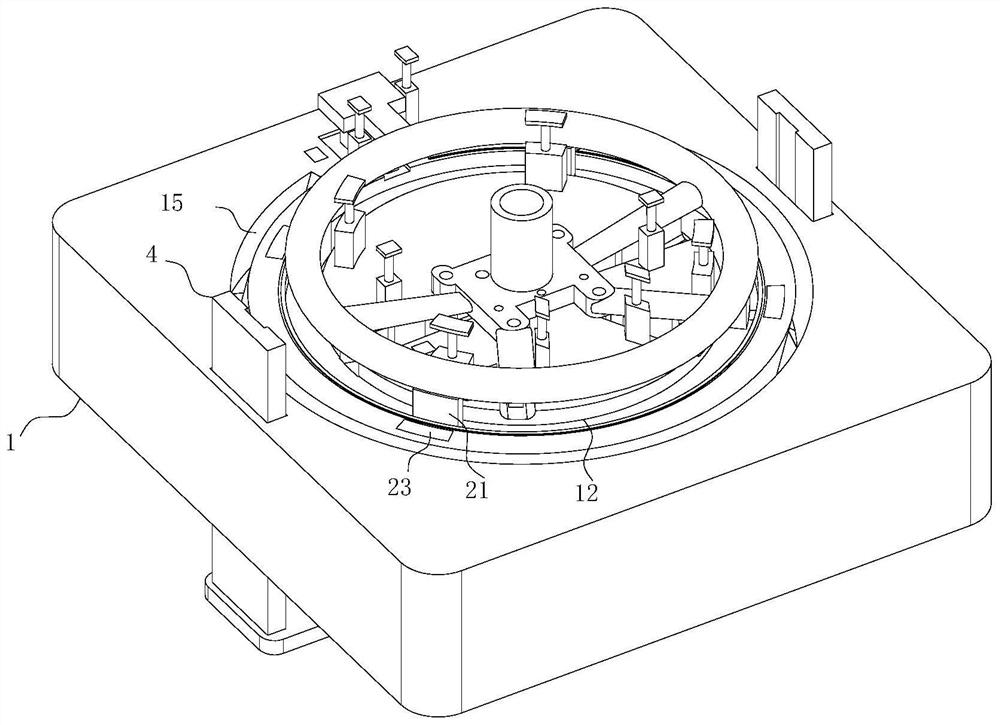

[0040] see Figure 1-15 , the present invention provides a technical solution: including a fixed die table 1 and a movable die table 7, the movable die table 7 is erected directly above the fixed die table 1 by pressing a linear module 8, and the fixed die table 1 and the movable die table 7 The opposite surfaces are respectively provided with half-width skeleton cavities for the steering wheel skeleton. After the fixed mold table 1 and the movable mold table 7 are covered with each other, the oppositely arranged skeleton cavities mutually enclose the forming cavity for the integral molding of the steering wheel skeleton. The top of the movable mold table 7 There is a pressure nozzle 70 for injecting liquid into the forming cavity;

[0041] The skeleton cavity includes a central cavity 10, a bracket cavity 12 and a disk cavity 13, which are respectively used to shape the disk cartridge frame 61, the disk support 60 and the disk skeleton 6 of the steering wheel skeleton. One si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap