Method for improving annealing uniformity of bell-type furnace

A bell-type furnace and uniformity technology, applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of annealing color difference, uneven temperature and uneven performance on the surface of stainless steel hot-rolled coil, and achieve the color difference and rolling of stainless steel hot-rolled coil. The effect of improving the thickness fluctuation after rolling, improving the uniformity, improving the color difference and the thickness fluctuation after rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] 1. Choose a bell-type furnace with a fan frequency of 65Hz for annealing, and discard the bell-type furnace below 40HZ.

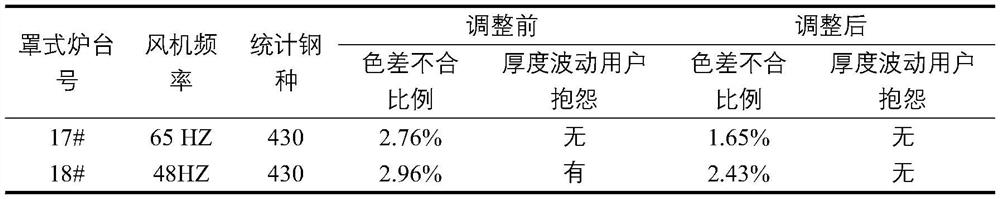

[0019] 2. The hydrogen flow rate of 2h before heating is increased from 9m 3 / h adjusted to 13m 3 / h; the hydrogen flow rate 1h before the end of the insulation is increased from 15m 3 / h adjusted to 23m 3 / h. The color difference of the selected bell furnace number before and after adjustment is out of proportion and the customer complaints are as follows

[0020]

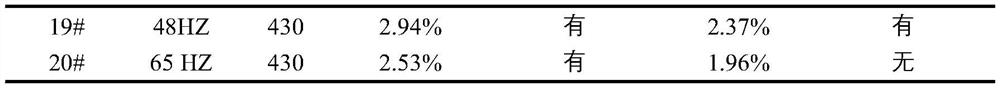

[0021] 3. The 19# and 20# furnaces were added to simulate the failure for 1h, and the time was added by 1.5 times (1.5h).

[0022]

[0023]

[0024] 5, 17, 18# furnace table is adjusted from 225 ℃ to 245 ℃ according to the furnace temperature, the color difference of the selected bell furnace number before and after adjustment is out of proportion (100% by weight) and customer complaints are as follows

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com