Classifiable waste coat recycling device

A recycling device and waste technology, applied in recycling technology, decomposition of fibrous substances, decomposition and recovery of textiles, etc., can solve the problems of difficulty in collecting batt and slowing down of batt collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

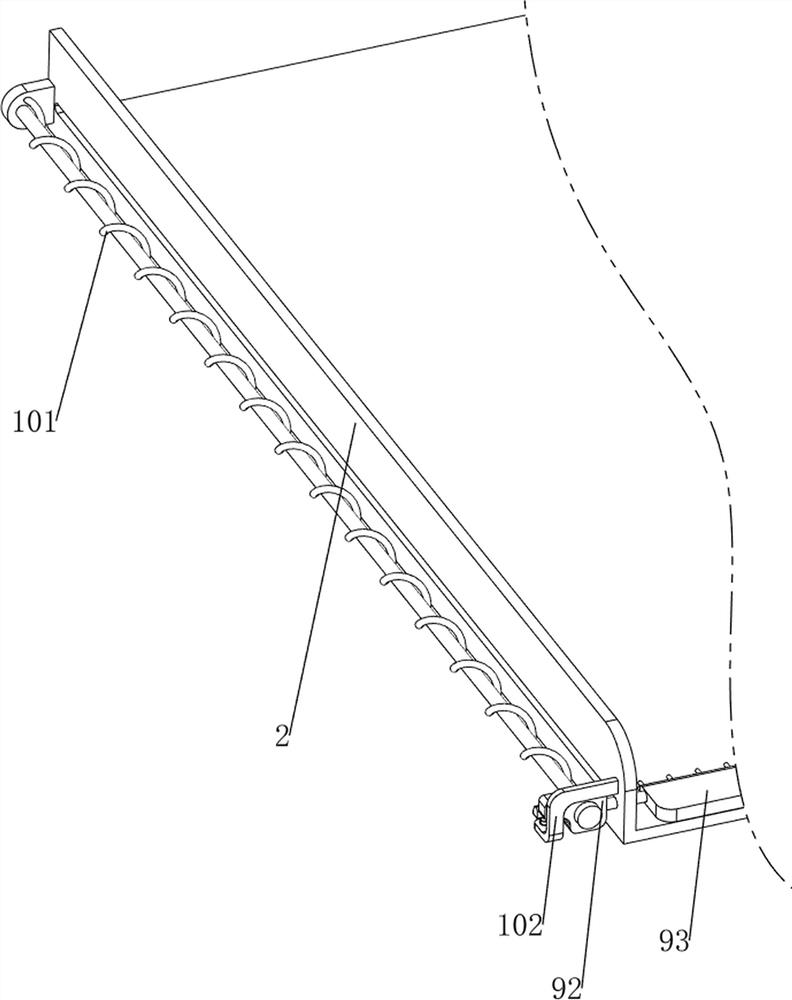

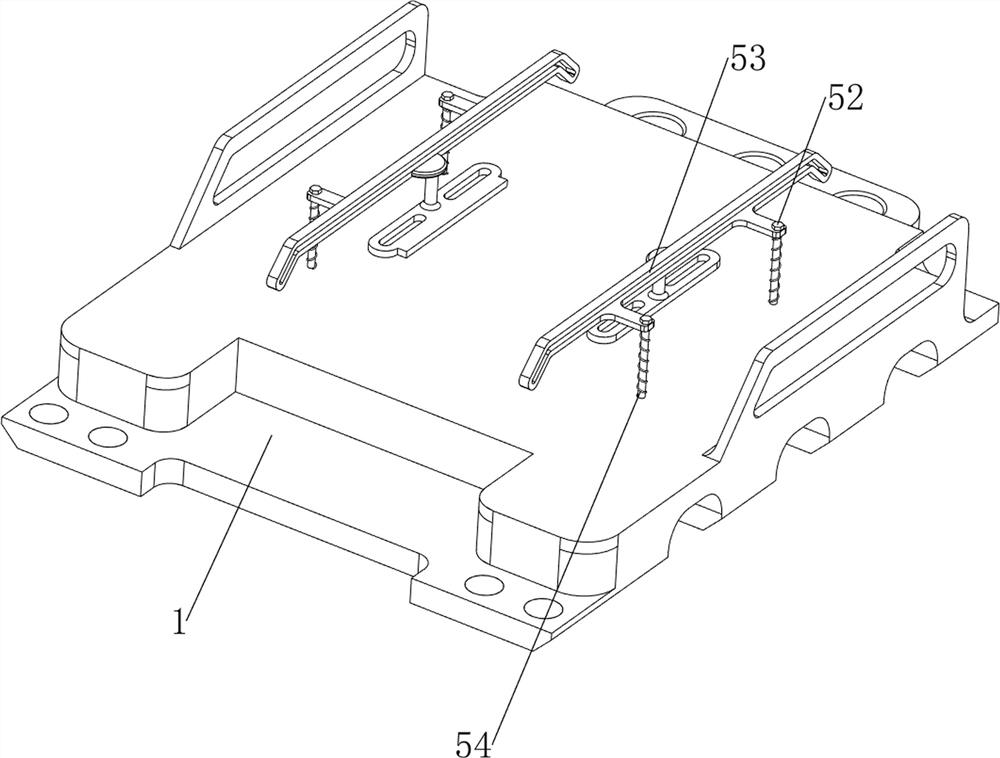

[0036] A sortable waste jacket recycling device, such as Figure 1-5 As shown, it includes a support plate 1, a first fixed frame 2, a first support frame 3, a rodless cylinder 31, a first cutter 4, a pressing mechanism 5 and a cutting mechanism 6, and the top of the support plate 1 is fixedly connected There is a first fixing frame 2, and the left and right sides of the first fixing frame 2 are provided with a first support frame 3, and the first support frame 3 is connected with a rodless cylinder 31 by means of bolts, and the rodless cylinders 31 are all sliding. A sliding rod is provided between the sliding rods, a first cutter 4 is connected between the sliding rods, a pressing mechanism 5 is provided on the first fixed frame 2, a cutting mechanism 6 is connected between the support plate 1 and the first fixed frame 2, and the cutting mechanism 6 For cutting waste jackets.

[0037] The pressing mechanism 5 includes a first fixing plate 51 , a first fixing rod 52 , a mova...

Embodiment 2

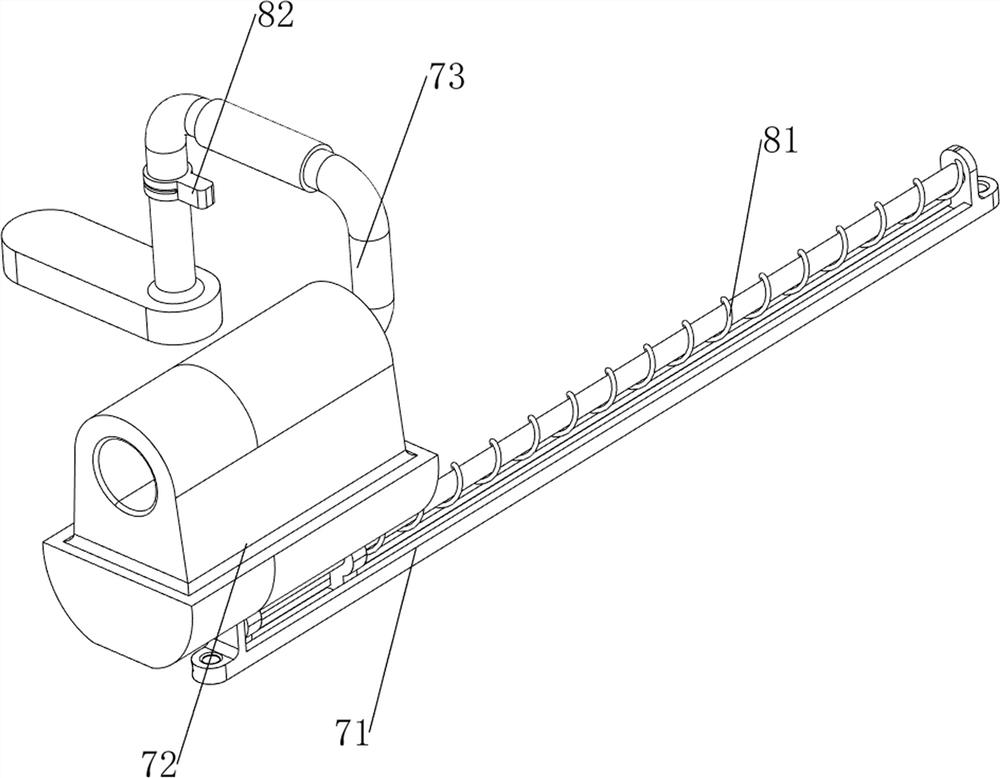

[0041] On the basis of Example 1, as figure 1 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a suction mechanism 7, and the suction mechanism 7 includes a slide rail 71, a movable frame 72, a suction pipe 73, a filter screen 74, a second support frame 75, a motor 76, a fan blade 77 and a charging frame 78 , the left and right sides of the top of the first fixed frame 2 are provided with slide rails 71, the slide rails 71 are slidably provided with a movable frame 72, the rear side of the movable frame 72 is provided with a suction pipe 73, and the inner front side of the movable frame 72 is A second support frame 75 is provided, a motor 76 is provided on the second support frame 75, a fan blade 77 is provided on the output shaft of the motor 76, and a filter screen 74 is provided in the movable frame 72, and the filter screen 74 is located on the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com