Cement pipeline attaching device for water conservancy project

A technology for cement pipelines and water conservancy projects, which can be used in hydroelectric power generation, pipes/pipe joints/fittings, sealing of engines, etc., and can solve problems such as inconvenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

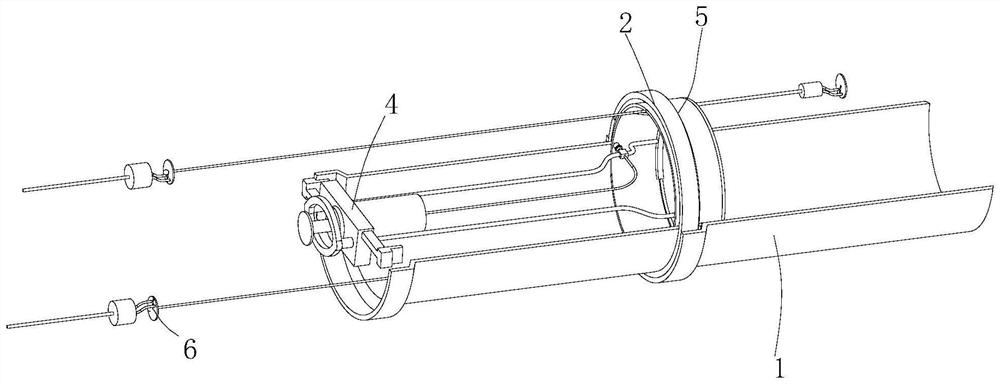

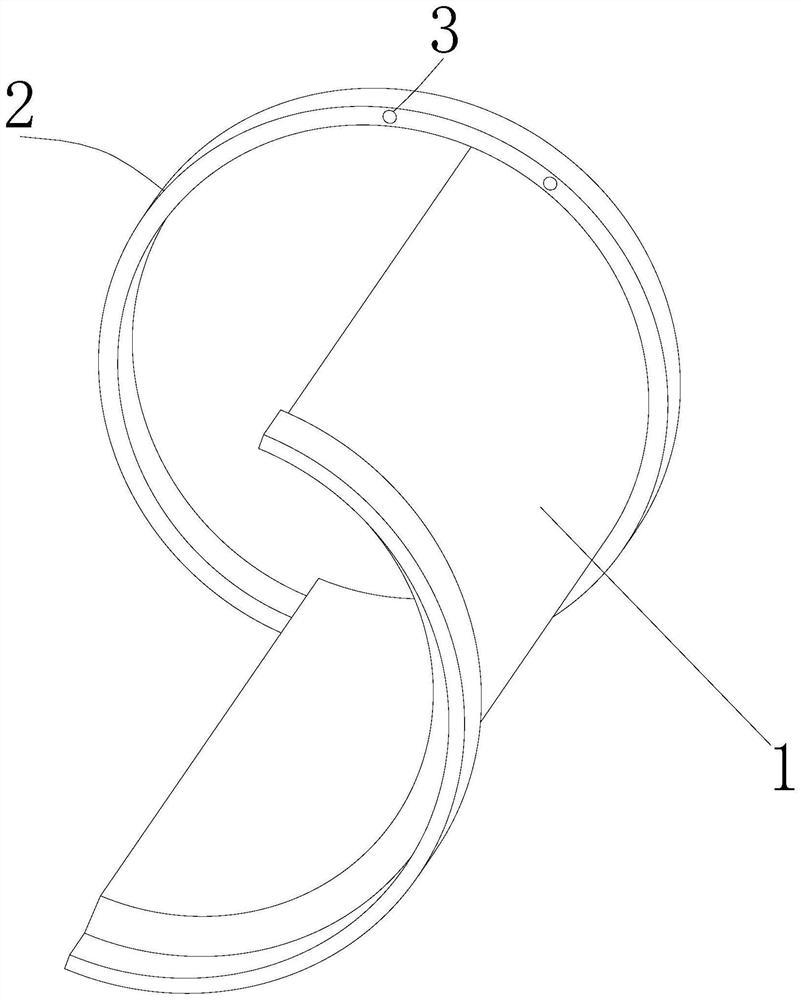

[0024] Example one, as Figure 1-6 As shown, it includes two cement pipes 1 spliced in sequence, the outer surface of the joint of the cement pipes 1 is sleeved with a rubber gasket 2, and the surface of the rubber gasket 2 is provided with a through hole 3 that penetrates the rubber gasket 2, and the number of the through holes 3 is Two, one of the through holes 3 is located at the top of the middle of the rubber gasket 2 and the other through holes 3 are located on one side. Through this setting, the through hole 3 at the lower end can be used for injection, and the through hole 3 at the uppermost end is exhausted so that the interior is filled. The sealant can be evenly distributed, and it is ensured that the gap is filled when the sealant is discharged from the through hole 3 at the upper end.

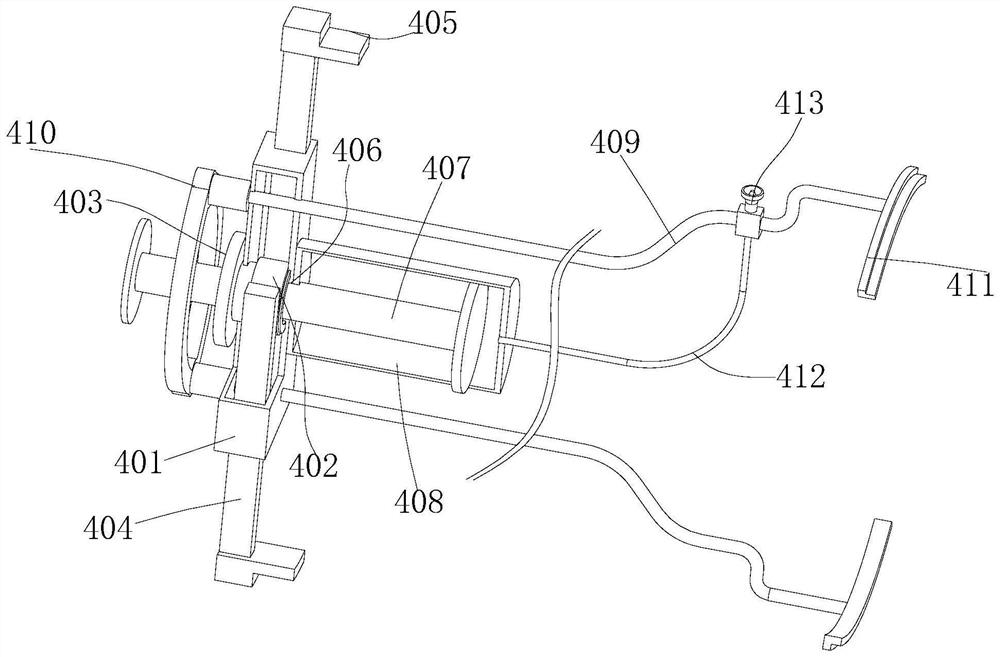

[0025] The interior of the cement pipe 1 is clamped with a fixing mechanism 4, and one end of the fixing mechanism 4 located inside the cement pipe 1 is clamped with a sealing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com