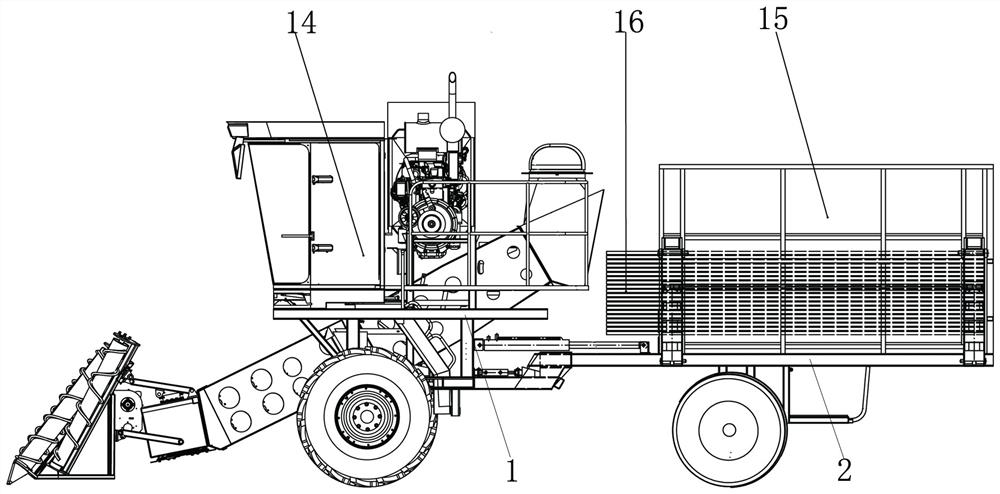

Telescopic whole-rod type sugarcane harvester frame

A frame and pole type technology, applied in the field of whole pole sugarcane harvesters, can solve the problems of reduced efficiency and inconvenient operation, and achieve the effects of reasonable overall structure, reduced working intensity and avoiding fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

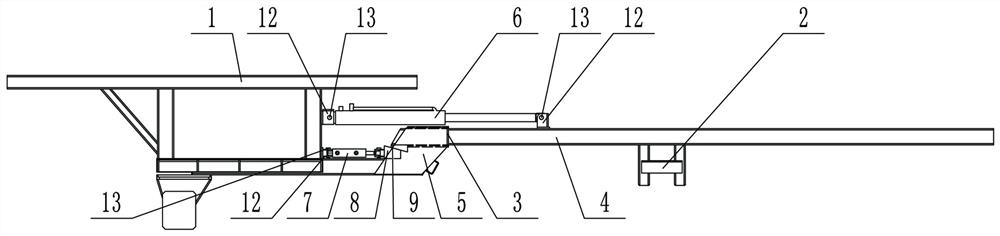

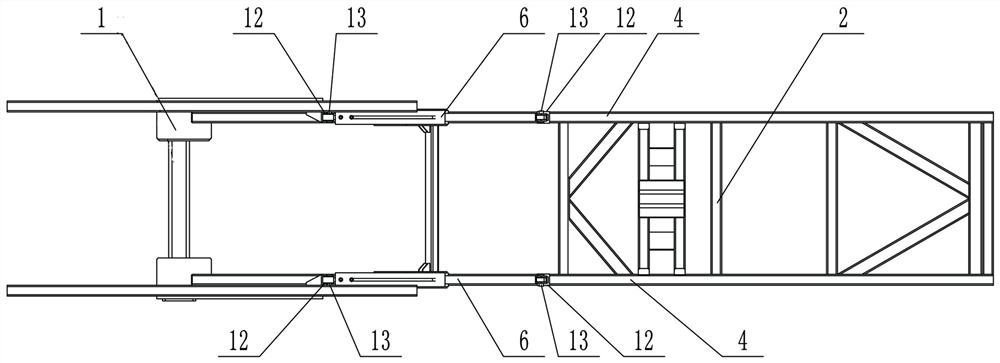

[0028] refer to Figure 1 to Figure 8 , a kind of retractable full pole type sugarcane harvester frame of the present invention is described in detail.

[0029] A retractable full-rod sugarcane harvester frame, such as Figure 1 to Figure 8 As shown, it includes a front-end vehicle frame assembly 1 and a rear-end vehicle frame assembly 2, and the front-end vehicle frame assembly 1 is as Figure 7 As shown, the rear frame assembly 2 is as Figure 8As shown, the front-end frame assembly 1 and the rear-end frame assembly 2 are slidably fitted through two sets of square tube guide rails 3 located on the left and right sides of the frame and a square tube beam 4 inserted in the square tube guide rails 3. For details, see Figure 6 , the square tube guide rail 3 is fixed on the rear side of the front frame assembly 1 through the support seat 5, and the square tube beam 4 is fixed on the front side of the rear frame assembly 2, between the front frame assembly 1 and the rear frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com