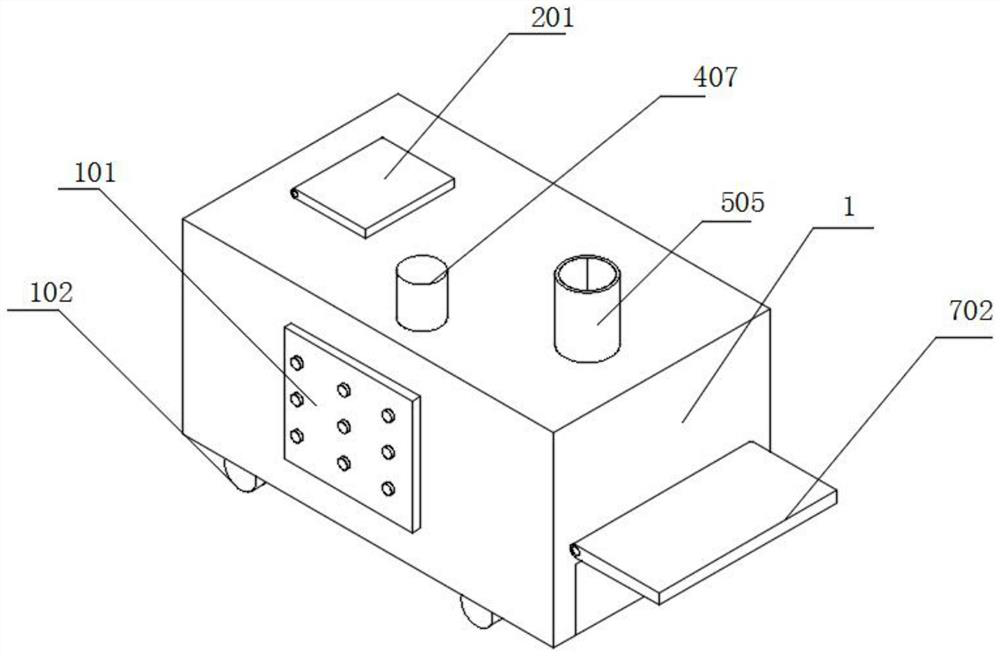

Ex-situ thermal desorption equipment for repairing organic contaminated soil

A technology of organic pollution and thermal desorption, which is used in the restoration of polluted soil, separation methods, and dispersed particle separation. The effect of blanking and preventing reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

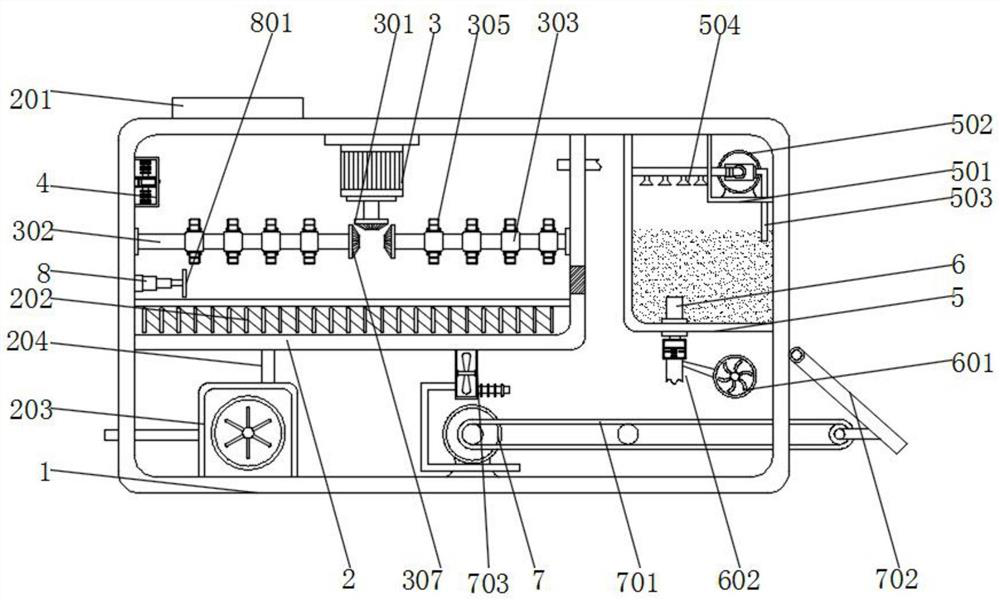

[0033] Example 2: see figure 2 and Figure 4 , an embodiment provided by the present invention: an ex-situ thermal desorption device for repairing organic polluted soil, a first motor 3 is installed on the inner top wall of the heating box 2, and a first motor 3 is installed on the output end of the first motor 3. Bevel gear 301, two sets of fixed shafts 302 are installed on the inner wall of the box 1, one end of the fixed shaft 302 is installed with a No. 2 bevel gear 307, the outer wall of the fixed shaft 302 is installed with a fixing ring 303, and the outer wall of the fixing ring 303 is installed with support rod , a rotating shaft 304 is installed at one end of the support rod, a turning chute 305 is installed on the outer wall of the rotating shaft 304, and a limit rod 306 is installed on the outer wall of the fixing ring 303. When turning the material, the first motor 3 is activated, and the first motor 3 rotates Drive the No. 1 bevel gear 301 to rotate, the No. 1 b...

Embodiment 3

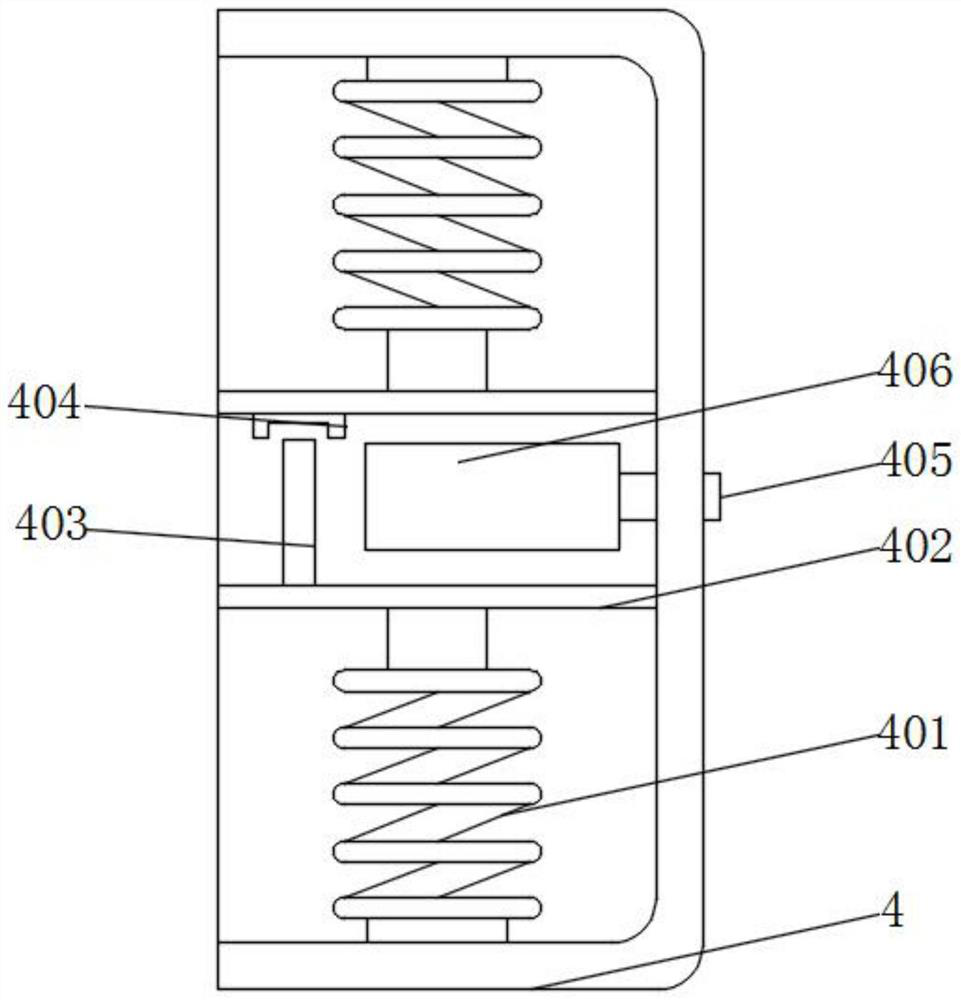

[0034] Example 3: see figure 2 and image 3 , an embodiment provided by the present invention: an ex-situ thermal desorption device for repairing organic contaminated soil, the inner top wall and inner bottom wall of the detector 4 are both installed with a first spring 401, and the first spring 401 A lift plate 402 is installed at the top, a conductive rod 403 is installed on the top of the lift plate 402, a conductive groove 404 is installed at the bottom of the lift plate 402, a connecting tube 405 is installed through the inner wall of the detector 4, and an expansion ball is installed at one end of the connecting tube 405 406, a warning light 407 is installed on the top of the box body 1. When the inside of the device is vacuumed, the gas inside the expansion ball 406 is drawn out through the connecting pipe 405, and the expansion ball 406 contracts, so that the first spring 401 extends and drives the lifting plates 402 to approach each other. , the conductive rod 403 i...

Embodiment 4

[0035] Example 4: see figure 2 and Figure 5 , an embodiment provided by the present invention: an ex-situ thermal desorption device for repairing organic polluted soil, the inner wall of the treatment box 5 is installed with a waterproof shell 501, the inner bottom wall of the waterproof shell 501 is installed with a water pump 502, and the water pump The input end of 502 is installed with a water inlet pipe 503, and the bottom of the water inlet pipe 503 extends into the interior of the treatment box 5, the interior of the treatment box 5 is filled with purified liquid, and the output end of the water pump 502 is installed with a spray pipe 504, and the spray pipe 504 One end extends out of the outer wall of the waterproof shell 501, a plurality of nozzles are installed at the bottom of the spray pipe 504, a one-way valve 602 is installed on the outer wall of the air inlet pipe 6, a fan 601 is installed on the inner wall of the box 1, and one end of the fan 601 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com