A casting mold separating device for pump casing casting

A casting mold and equipment technology, applied in the field of auxiliary casting equipment, can solve the problems of easy sticking of residual casting sand on the inner wall of the mold frame, cumbersome operation steps, troublesome and inconvenient use, etc., to achieve convenient and time-saving use, reduce residue, reduce cost and The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

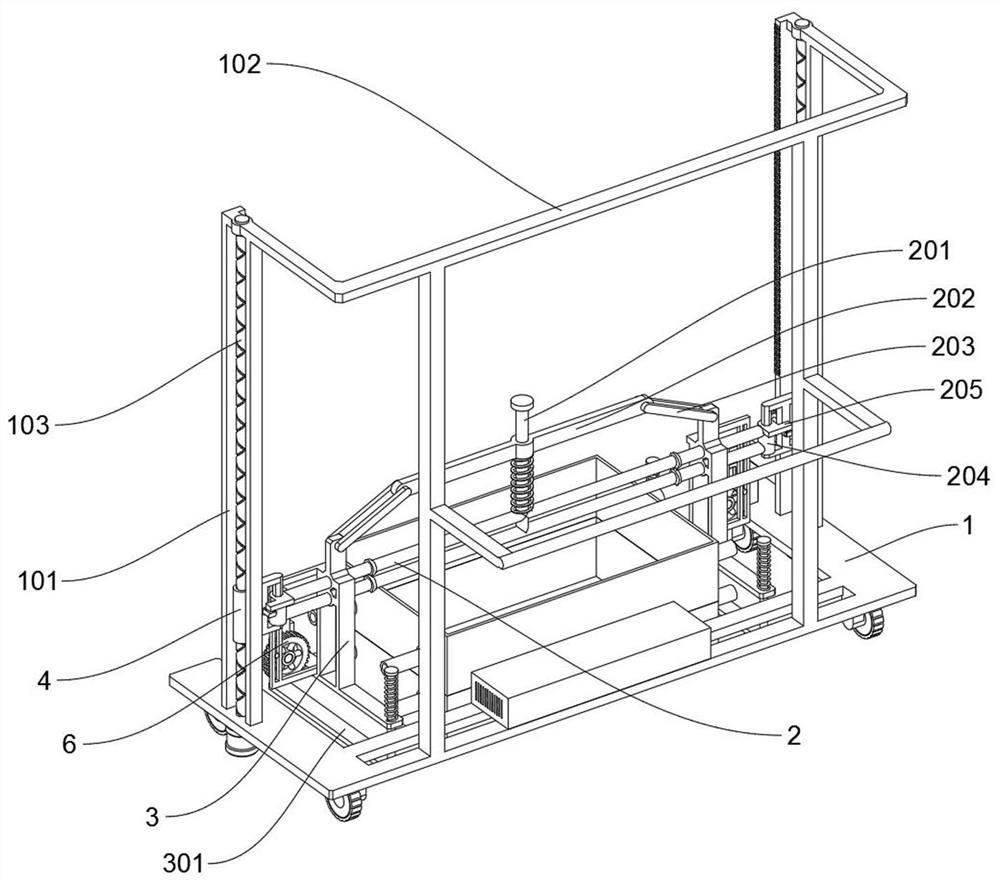

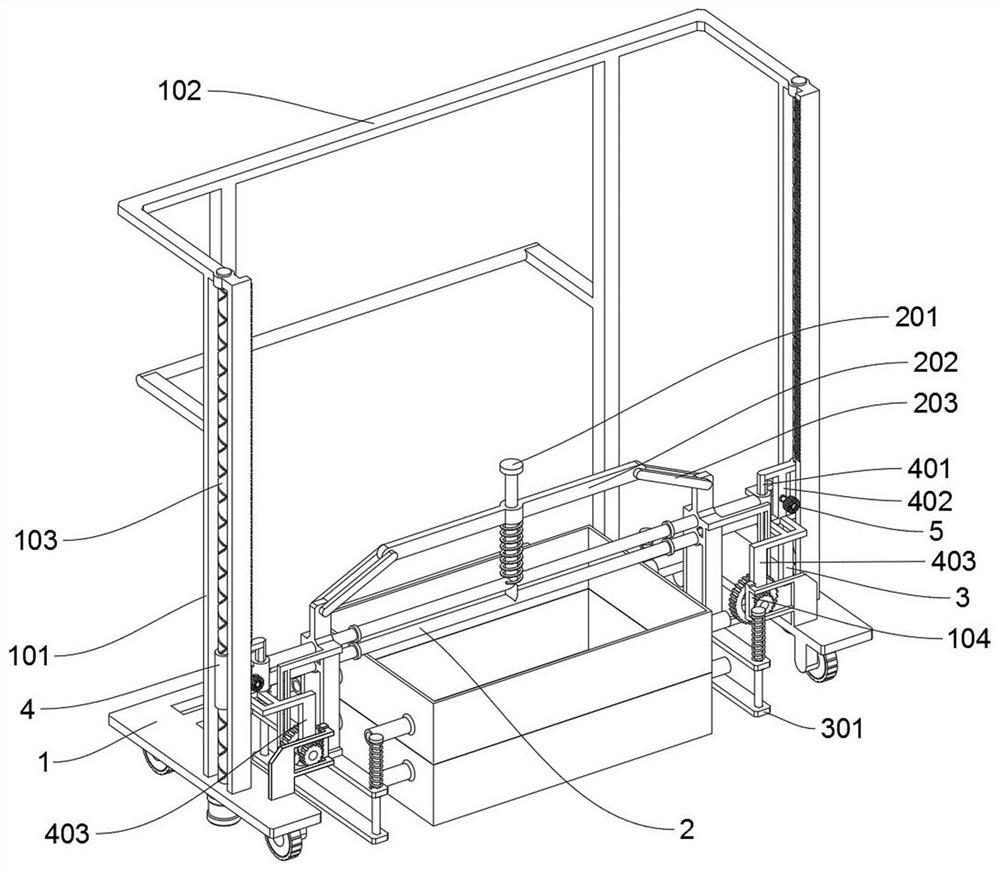

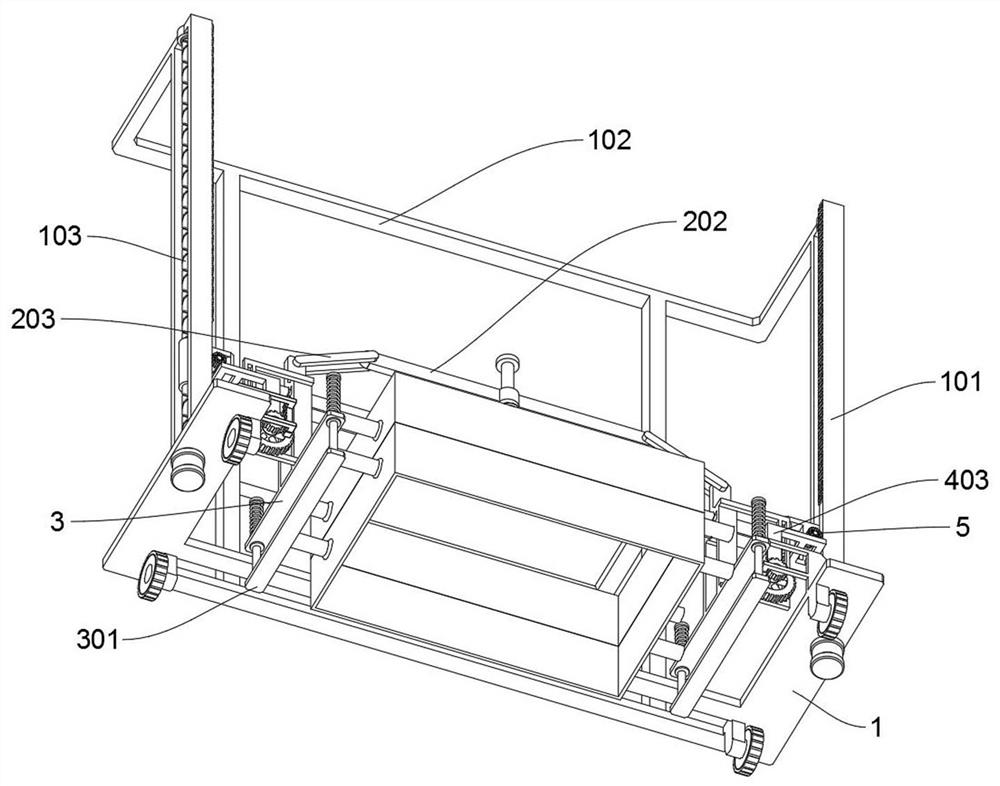

[0031] see Figure 1 to Figure 12 ;

[0032] The present invention proposes a casting mold separating device for pump casing casting, including: a chassis 1; the chassis 1 includes a vertical support rod 101 and a reciprocating screw rod 103, and the chassis 1 has a zigzag structure as a whole, which consists of two parts: left and right. The longitudinal bracing plate and the two transverse bracing connecting rods which are welded at intervals between the rear end sections of the two longitudinal bracing plates are welded together to form, among which, four vertical bracing rods 101 are symmetrically welded to the top of the front half of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com