Welding equipment for positioning piece of heating base

A technology of welding equipment and positioning parts, which is applied in the field of welding equipment for positioning parts of heating bases, can solve the problems of automatic bonding of heat-conducting substrates without heating elements, etc., achieve the effects of convenient automatic assembly, low welding efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described below with reference to the accompanying drawings and specific embodiments.

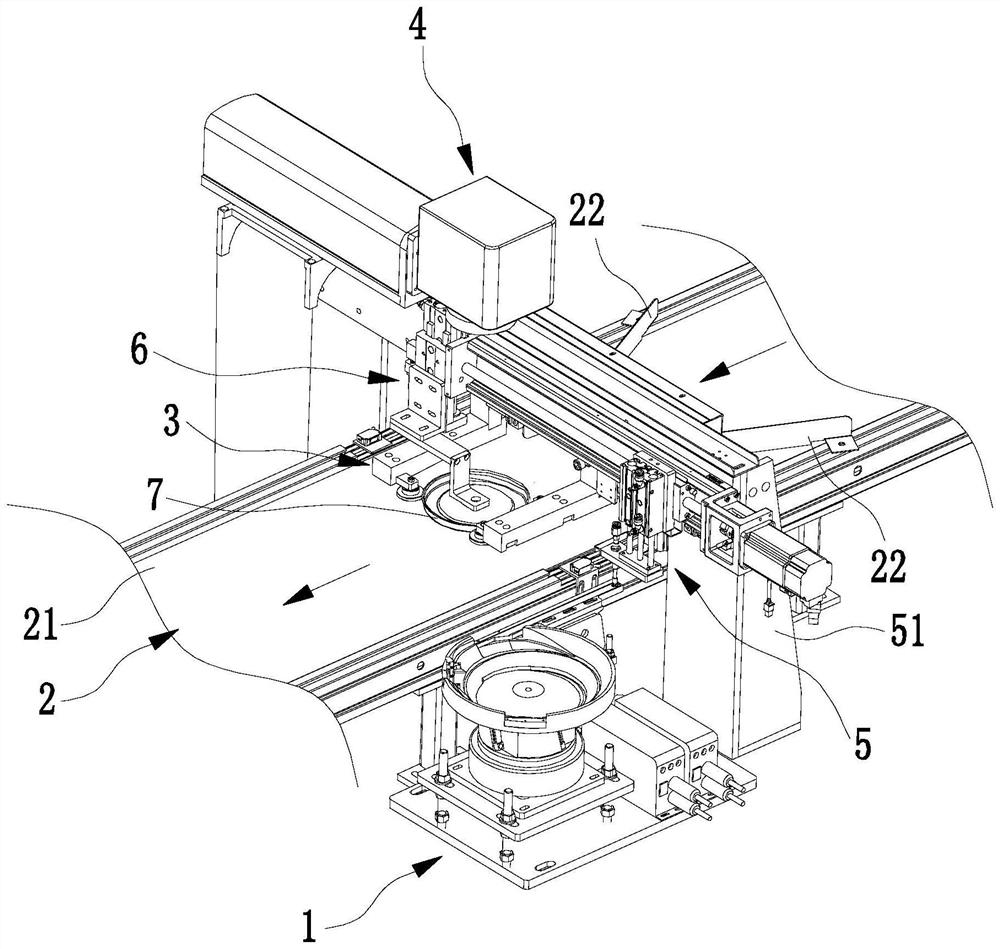

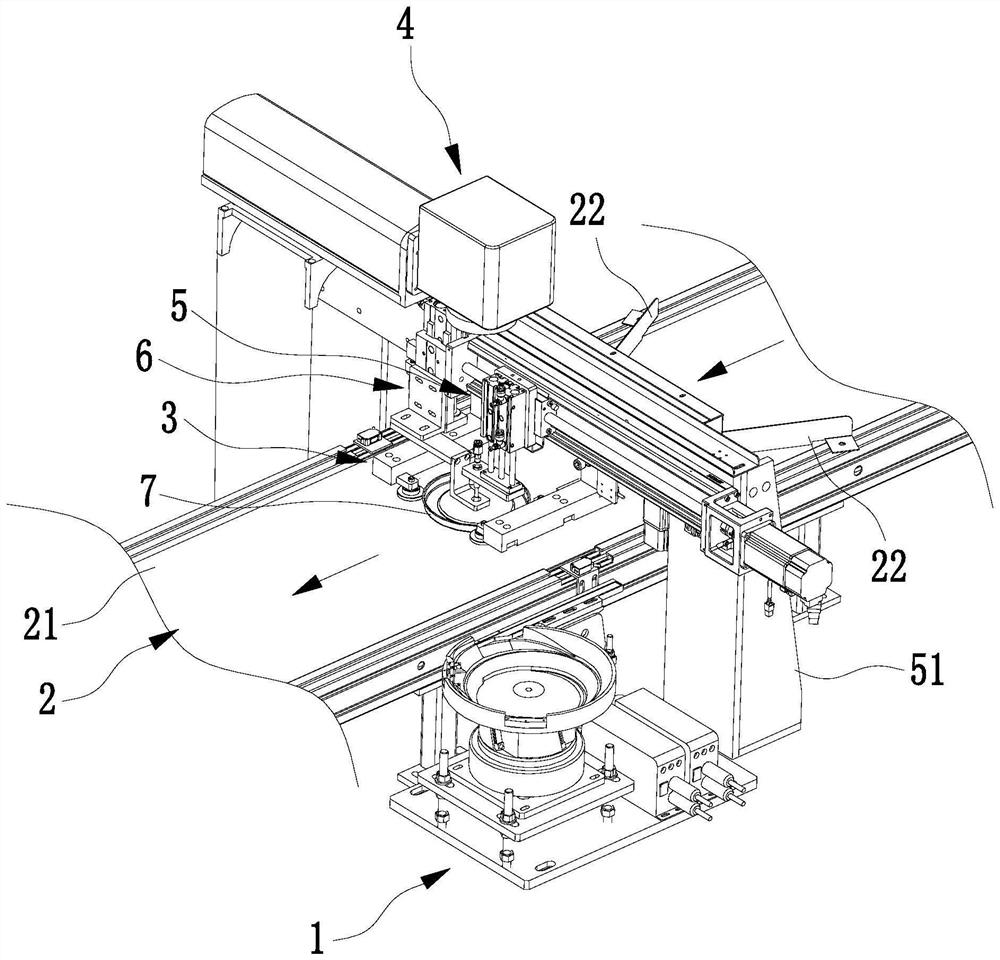

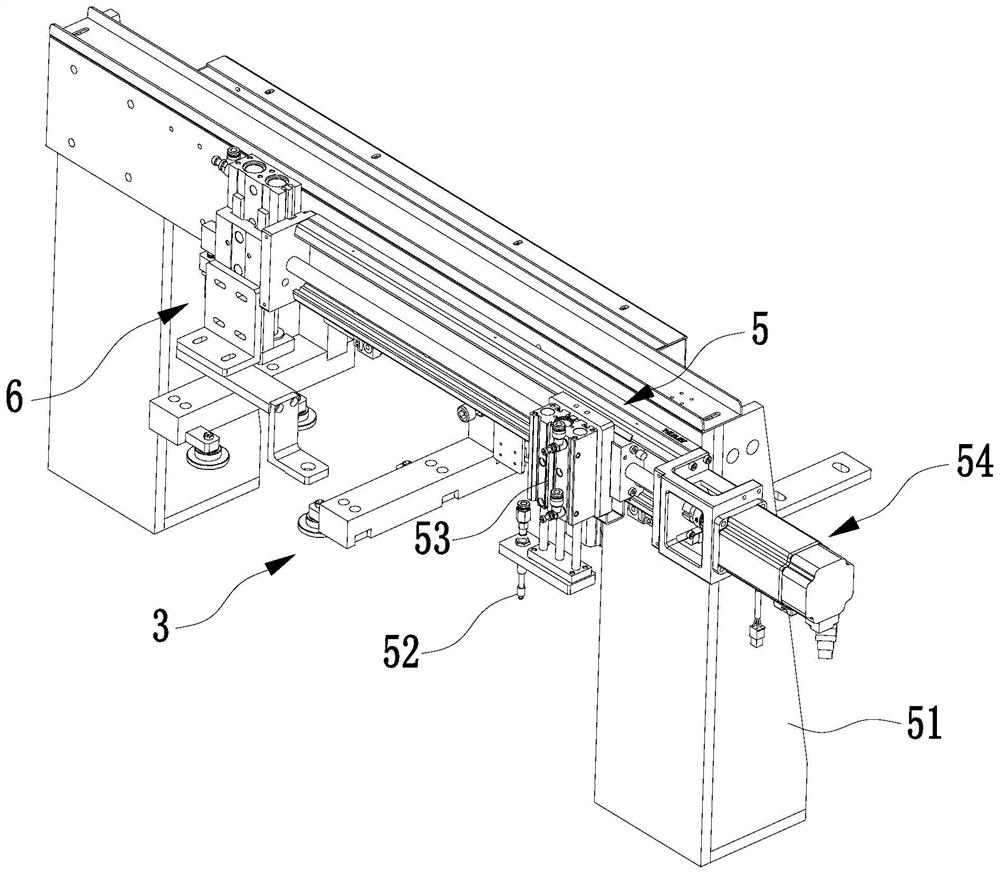

[0035] see figure 1 , figure 2 , image 3 and Figure 7 , the heating base positioning member welding equipment in this embodiment includes a conveying device 1, a feeding device 2, a centering device 3, a laser welding device 4, a transfer mechanism 5 and a welding guide mechanism 6, and the conveying device 1 includes a positioning member. 71 conveyors 12 and helical vibrating discs 11 are arranged and conveyed. The outlet of the helical vibrating discs 11 is connected to the feeding end of the conveyor 12. The end of the conveyor 12 is equipped with a reclaiming part 130; the feeding device 2 includes The conveying surface 21 for conveying the heat-conducting substrate 7; the centering device 3 is arranged on the upper side of the conveying surface 21 for centering and positioning the heat-conducting substrate 7; the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com