Rubber gasket hot-pressing forming machine

A technology for rubber gaskets and molding machines, which is applied in the directions of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc. Save time and avoid excessive impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings. Here, the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, but not to limit the present invention.

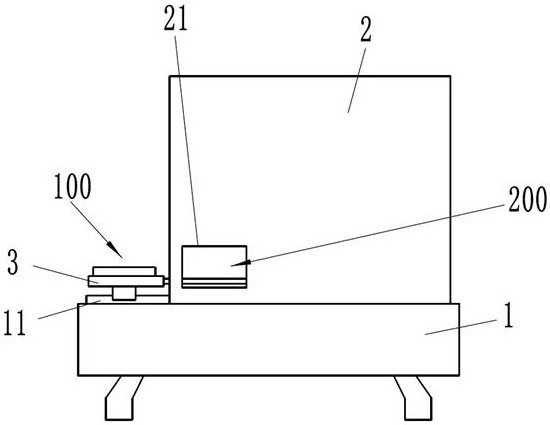

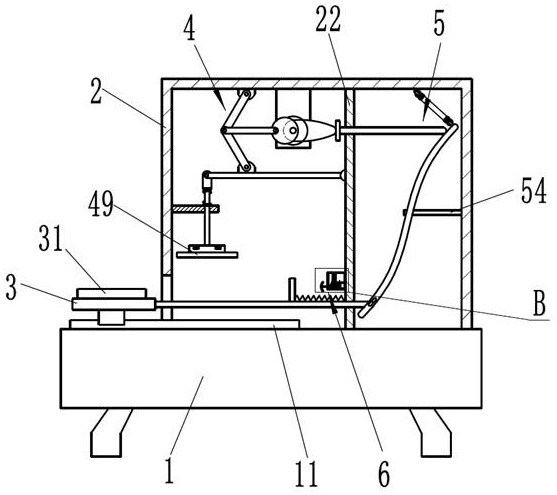

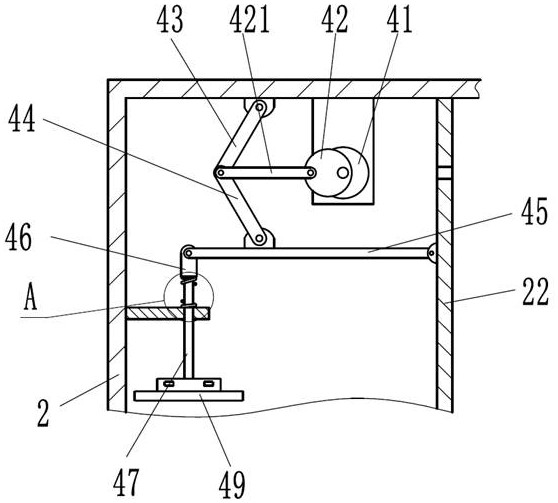

[0029] refer to Figure 1 to Figure 8 ,like figure 1 and figure 2 The shown rubber gasket thermoforming machine includes a base 1 and a processing box 2, the left end of the processing box 2 has a disassembly station 100, and the interior of the processing box 2 has a processing station 200, The base 1 is provided with a hot pressing mold 31, the hot pressing mold 31 is slidably installed by the sliding base 3 and the slide rail 11 of the base 1, and the processing station 200 is provided with a hot pressing mechanism 4, The right side of the hot pressing mechanism 4 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com