Printing equipment capable of rapidly drying printing ink

A fast drying and printing ink technology, applied in general parts of printing machinery, printing, printing machines, etc., can solve the problems of wasting energy, incomplete ink drying, etc., and achieve the effect of increasing evaporation, increasing temperature, and increasing drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

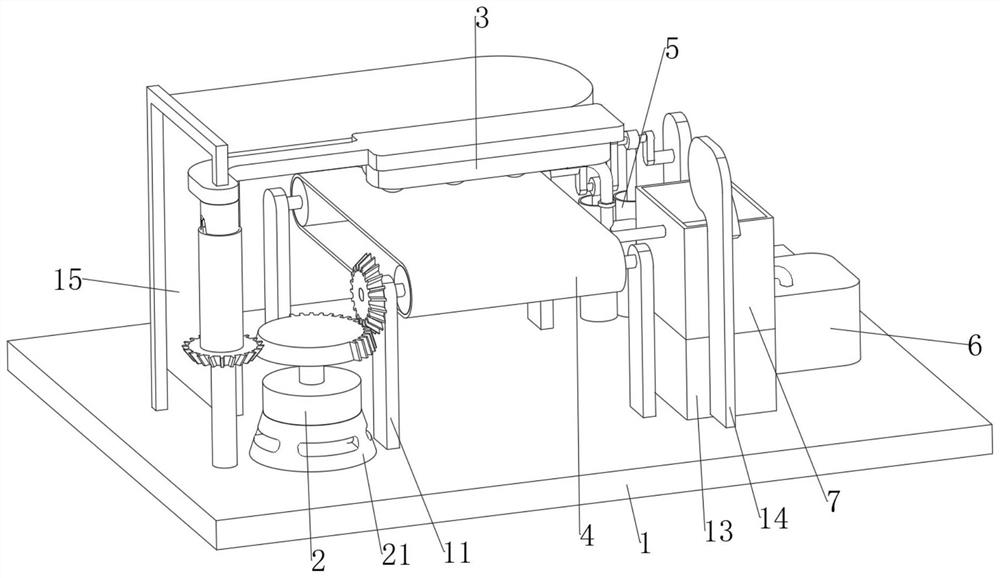

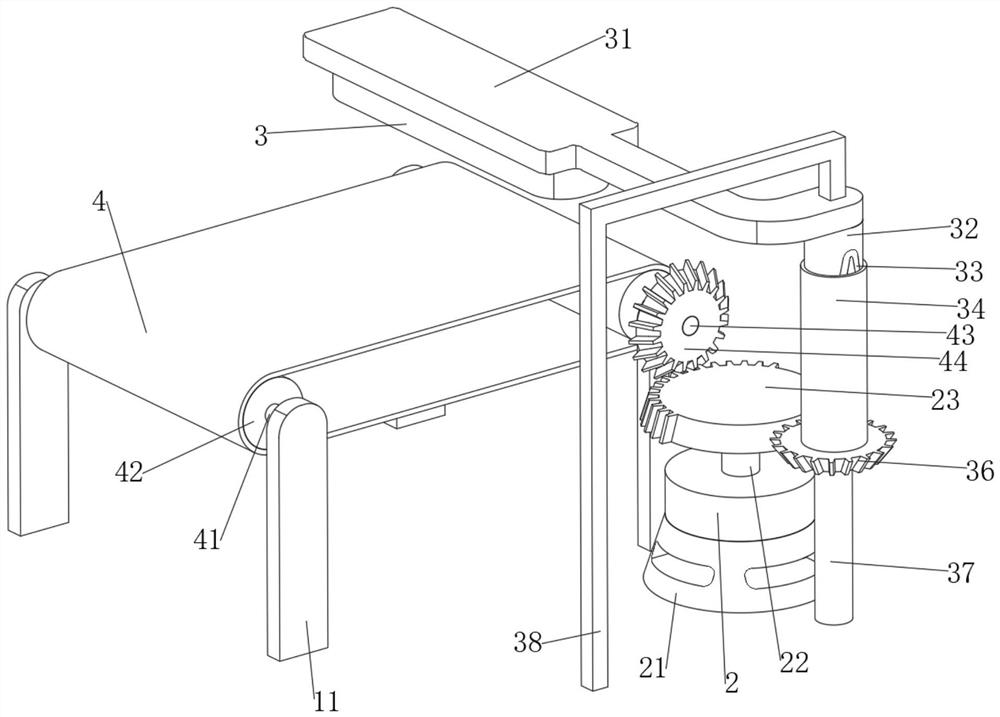

[0029] The present invention provides a technical solution: a printing ink rapid drying printing apparatus, comprising a load-bearing plate 1 and an ink printer 3, a load-bearing plate 1 fixed connection to four first support plates 11 and motor frame 21, each two first support plates 11 on the opposite surface of the fixed axis rotation connection with the first rotation axis 41 and the second rotation axis 43, the second rotation axis 43 extends out of the first support plate 11 at one end fixed connection has a first complete bevel gear 44, The first rotating shaft 41 and the second rotating shaft 43 are provided with a conveyor mechanism for transmitting the paper to be printed, the load-bearing plate 1 is connected to the rotating rod 37 on the fixed shaft rotation, the upper surface of the rotating rod 37 is fixed to be connected to the second complete bevel gear 36, the second complete bevel gear 36 is provided with a printing mechanism for printing paper, the motor frame 2...

Embodiment 2

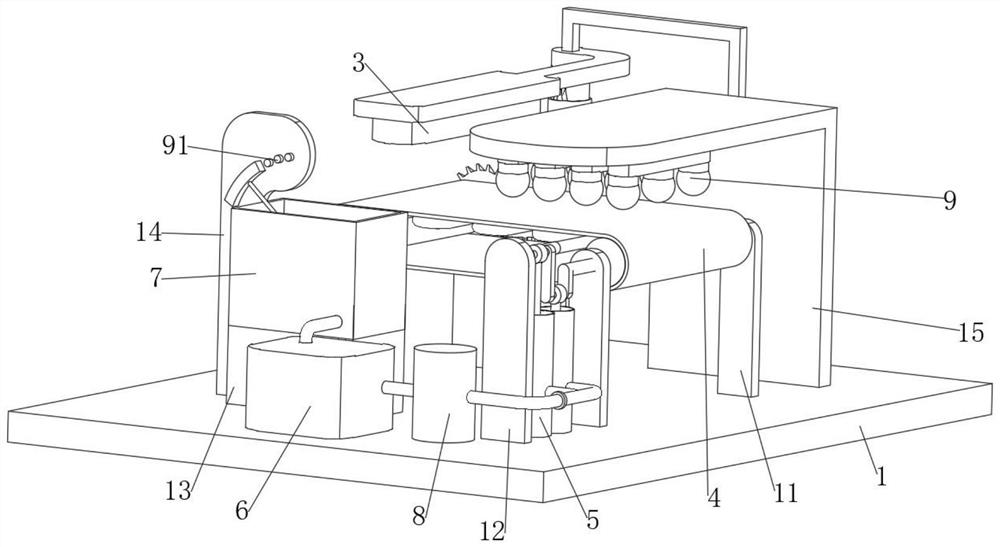

[0044] Substantially the same as Example I, further, the load-bearing plate 1 is provided with a heating mechanism for increasing the temperature of the printing environment, the heating mechanism comprises a heater 8 fixed to the load-bearing plate 1, the first delivery pipe 55 runs through the heater 8, the second conveyor pipe 57 is provided with a bending section, the bending section is located directly below the conveyor belt 4.

[0045] See Figure 5 and Figure 7 , when the water in the water tank 6 passes through the heater 8, the water will heat up into a higher temperature of water, and then flow into the second conveyor pipe 57 through the piston cylinder 57, because the second conveyor pipe 57 is provided with a bending section, the bending section is located directly below the conveyor belt 4, so that the temperature of the surrounding environment of the conveyor belt 4 is increased, thereby increasing the evaporation of the ink, thereby assisting in increasing the dryin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap