Rock sample lifting device and mounting structure thereof

A lifting device and rock sample technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of high cost of independent equipment, occupying large space and space, inconvenient operation, etc., and achieve the effect of simple structure, high reliability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

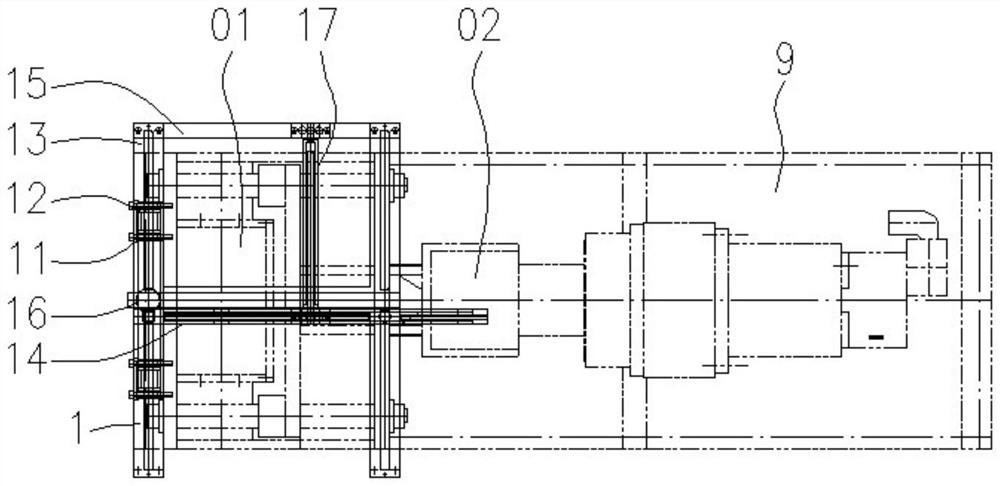

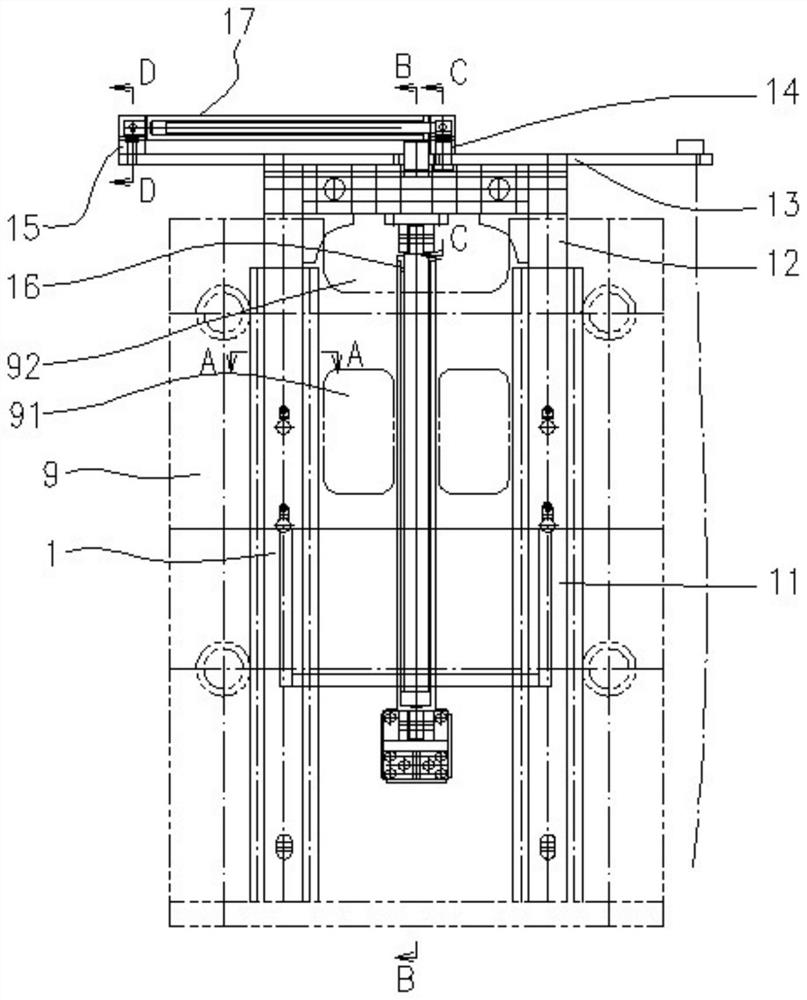

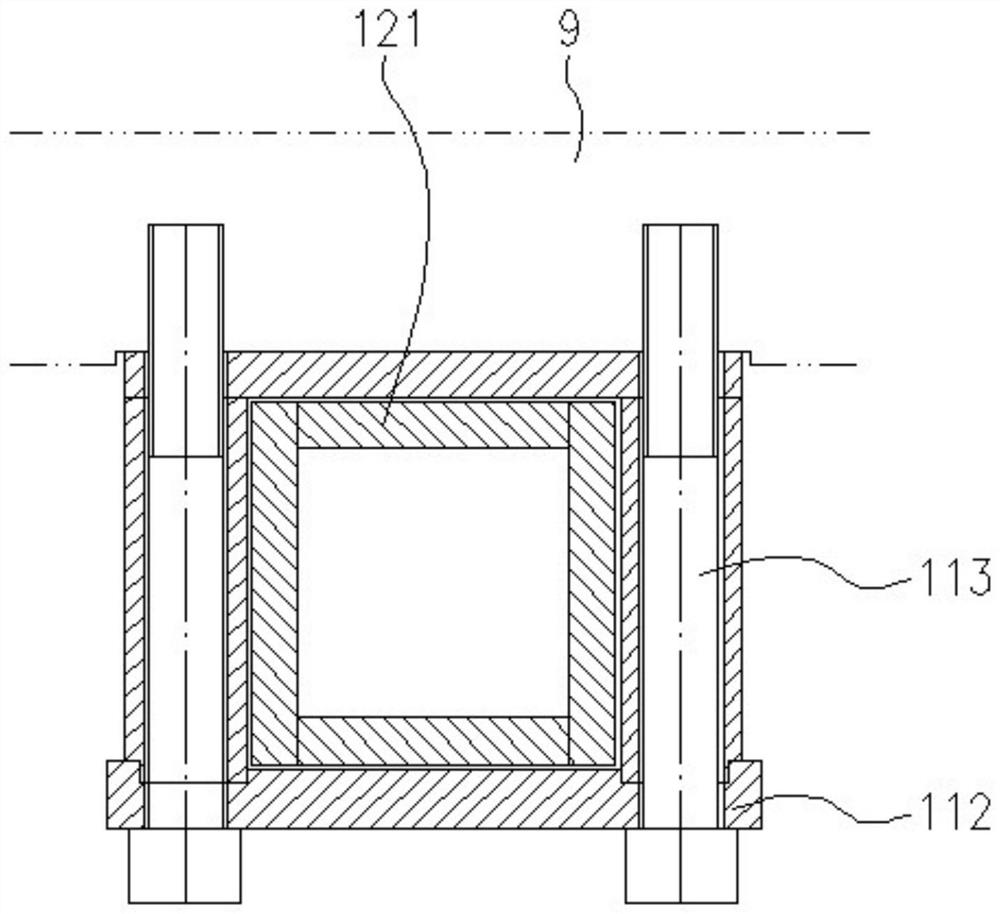

[0032] like Figure 1-11 As shown, the present invention discloses a rock sample lifting device 1, including a guide frame 11, a lifting platform 12, a lifting cylinder assembly 16, a push platform 13, a connecting rod assembly 15, a push rod assembly 14 and a push cylinder 17. The lift platform is guided by the guide frame to lift and lower under the telescopic action of the lift cylinder assembly. The push platform is installed on the lifting platform and goes up and down synchronously with the lifting platform. Both the connecting rod assembly and the push rod assembly are mounted on the push platform and extend in the front and rear horizontal directions. The pushing platform is provided with two front and rear guide structures extending horizontally from left to right, and the pushing rod assembly is slidably connected to the pushing platform left and right through the guide structures. The connecting rod assembly is fixed relative to the push platform. The pushing oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com