Integral type decorative wall body with embedded pipelines and manufacturing method and mold of integral type decorative wall body

A pre-buried pipeline, integrated technology, applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of poor corrosion resistance of wooden keels, unfavorable green environmental protection, easy to fall and hurt people, etc., to reduce cutting dust pollution and Noise pollution, reduction of line pipe grooving and repair and reinforcement, increased variety and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

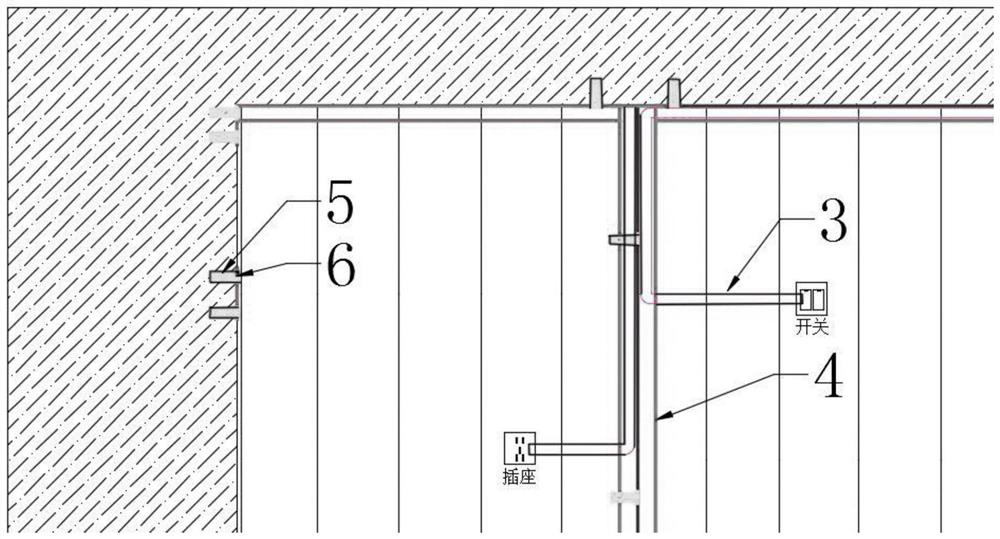

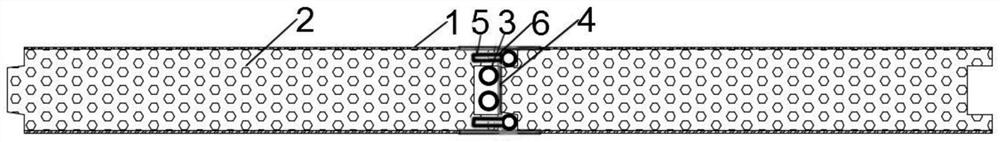

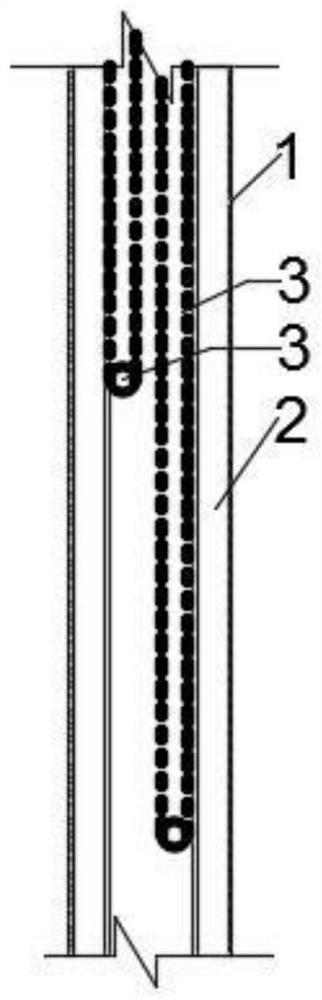

[0042] Please refer to the attached Figures 1 to 10 , the present invention provides an integral decorative wall 100 with pre-embedded pipelines, including an assembled composite wall panel 1, a decorative layer 2 and an electromechanical integrated pipeline 3, the assembled composite wall panel 1, the decorative layer 2 and the electromechanical integrated pipeline 3. The integrated pipeline 3 is cast in one piece. In the present invention, the assembled composite wall panel 1 and the decorative layer 2 are combined and bonded together. The composite wallboard 1 and the finishing layer 2 are combined into one, which effectively replaces the application of the traditional surface layer on the secondary wall, saves the wall base leveling materials, adhesive materials, etc., reduces the number of wall decoration processes, and improves the construction efficiency.

[0043] Specifically, two sides of the prefabricated composite wall panel 1 are also provided with a splicing gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com