Durability testing device for hydrogen circulating pump

A technology of durability test and circulating pump, which is applied to electrical components, fuel cells, electrochemical generators, etc., can solve the problem of inability to verify the durability of hydrogen circulating pump, and achieve the effect of saving development costs and accelerating verification time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

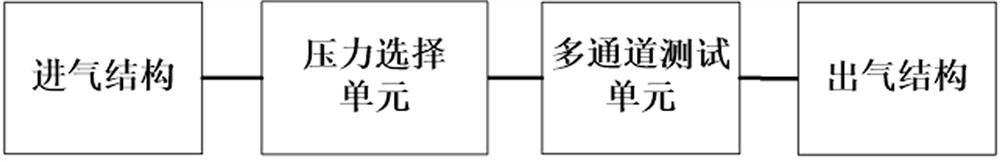

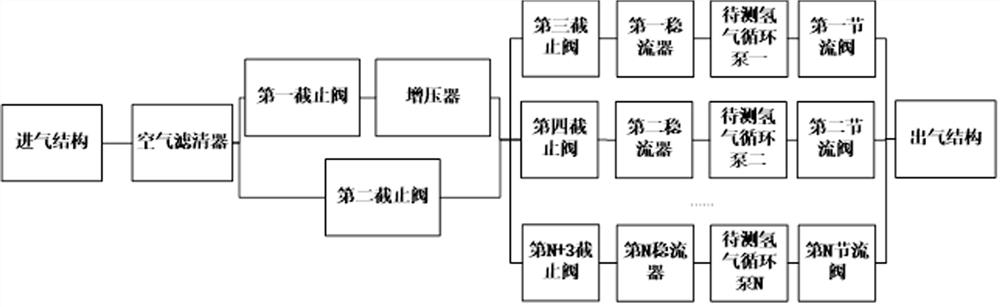

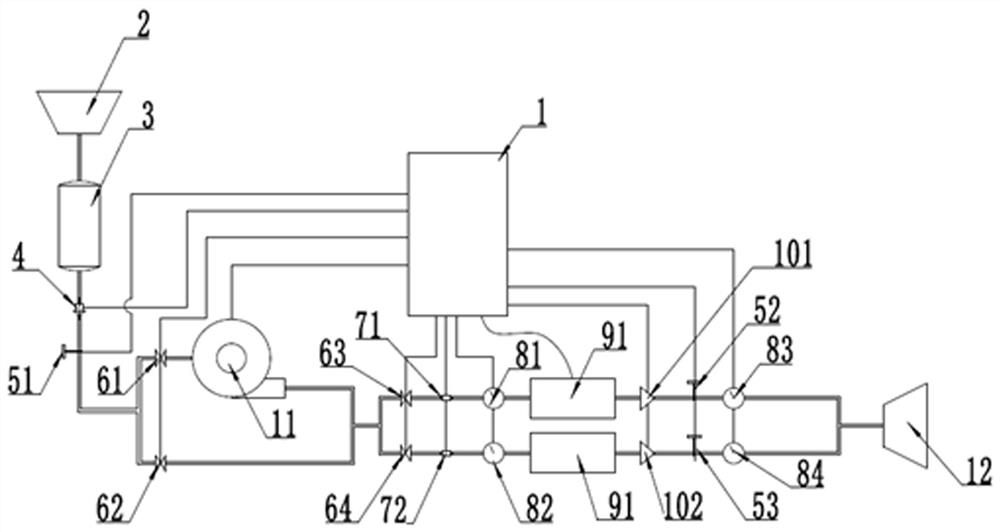

[0054] An embodiment of the present invention discloses a durability test device for a hydrogen circulating pump, such as figure 1 As shown, it includes a controller and an air intake structure, a pressure selection unit, a multi-channel test unit, and an air outlet structure connected in sequence.

[0055] Each channel in the multi-channel test unit is independent and parallel to each other, and each channel is provided with a hydrogen circulating pump to be tested (the durability test of the hydrogen circulating pump to be tested can be performed independently) and a hydrogen circulating pump to be tested. It is a control device for regulating the flow and pressure of the input gas of the hydrogen circulating pump to be tested.

[0056] The inlet structure is used to input gas such as hydrogen or a substitute gas for hydrogen.

[0057] The pressure selection unit is used to output the gas of the set pressure according to the control of the controller.

[0058] Outlet struc...

Embodiment 2

[0062] Improvements are made on the basis of the device described in Example 1, and the shapes of the air inlet structure and the air outlet structure are both trumpet-shaped. Among them, the inner diameter of the intake end of the intake structure should be larger than the inner diameter of the exhaust end, the intake end is set to face upward, the inner diameter of the intake end of the outlet end of the air outlet structure is smaller than the inner diameter of the exhaust end, and the exhaust end is set to face the test device. side.

[0063] Preferably, the control equipment on each channel of the multi-channel test unit includes a shut-off valve, a flow stabilizer such as Figure 2~3 shown. Wherein, after the stop valve and the flow regulator are connected end to end in sequence, they are connected to the inlet end of the hydrogen circulating pump to be tested in the channel.

[0064] The output end of the controller is respectively connected with the control ends of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com