Spraying polyurethane elastomer and production method thereof

A technology of spraying polyurethane and elastomers, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of polyurethane prone to creep and permanent deformation, and achieve excellent elasticity, excellent elongation, and high tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

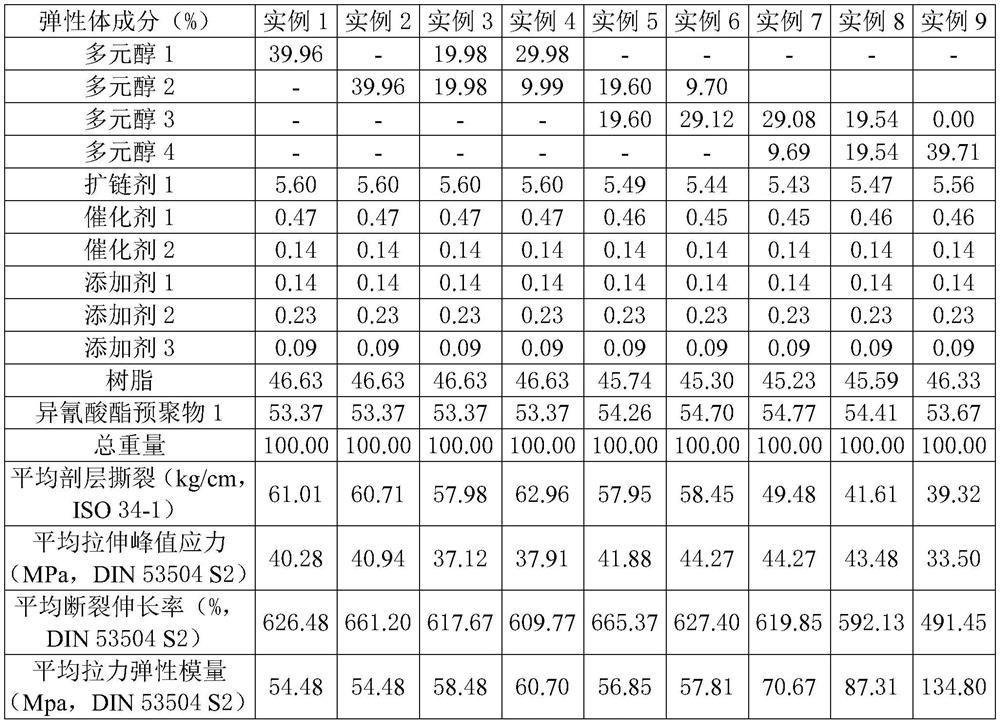

[0059] Polyol 1 is a polyester polyol initiated by adipic acid-ethylene glycol-1,4-butanediol, and the average number of hydroxyl groups is 56.

[0060] Polyol 2 is a polyester polyol initiated by adipic acid-ethylene glycol-1,4-butanediol, and its structure is different from that of polyol 1, and the average number of hydroxyl groups is also 56.

[0061] Polyol 3 is a polyester polyol initiated by adipic acid-ethylene glycol-1,4-butanediol, and the average number of hydroxyl groups is 80.

[0062] Polyol 4 is a graft polyester polyol with an average hydroxyl number of 60.

[0063] Polyol 5 is a glycerol-initiated polyether polyol including propylene oxide and ethylene oxide, and has a hydroxyl number of 35.

[0064] Polyol 6 is a dipropylene glycol initiated polyether polyol with 29 hydroxyl groups.

[0065] Polyol 7 is a graft polyol with 32% solids (1:2 acrylonitrile:styrene) and a hydroxyl number of 24.

[0066] Polyol 8 is a polytetrahydrofuran polyether polyol, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com