Scraper conveyor fault detection method and system and storage medium

A scraper conveyor and fault detection technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as expanding scraper conveyor failures, scraper conveyor failures, and complex working conditions. , to avoid further expansion of faults, save power consumption, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present application will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present application, and are not intended to limit the present application.

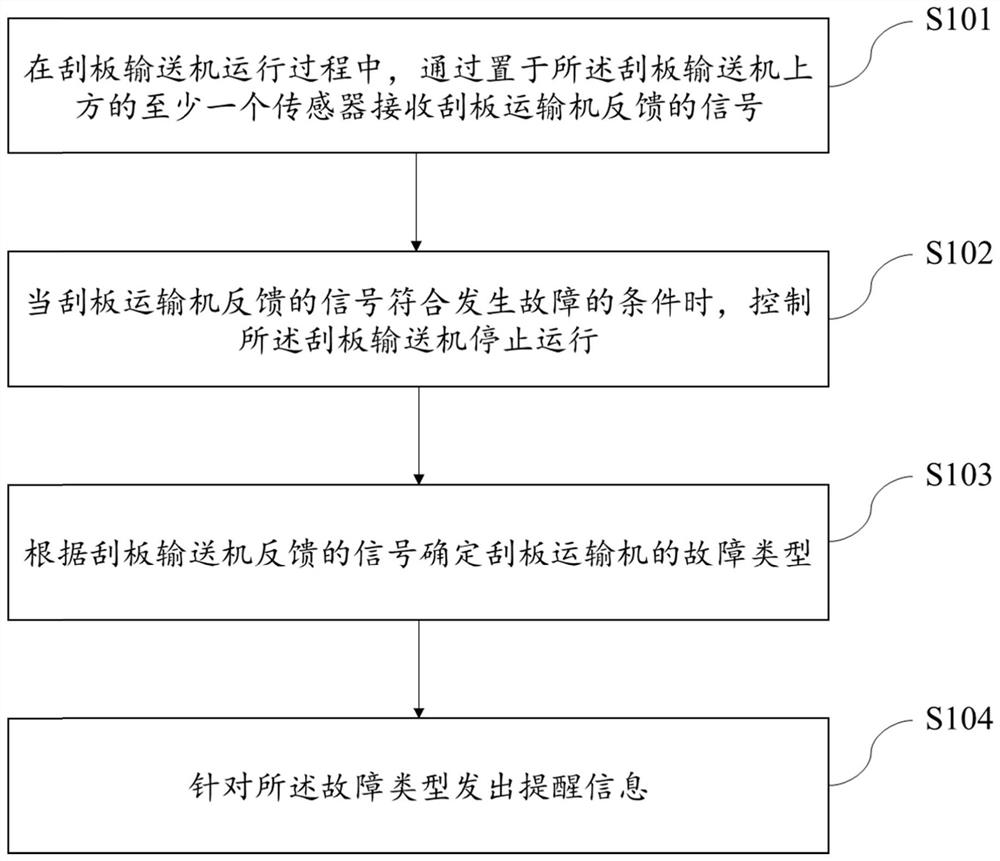

[0049] figure 1 It is a flow chart of a scraper conveyor fault detection method in an embodiment of the present application. This method can be used to detect the running status of the scraper conveyor in real time. When various faults are detected, it will stop in time and send an alarm information. like figure 1 As shown, the method can be implemented as the following steps S101-S104:

[0050] In step S101, during the operation of the scraper conveyor, a signal fed back by the scraper conveyor is received through at least one sensor placed above the scraper conveyor;

[0051] In step S102, when the signal fed back by the scraper conveyor meets the failure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com