Method for reducing copper nodules on surface of high-temperature and high-ductility copper foil

A copper foil, high temperature technology, applied in electroforming, electrolysis process and other directions, can solve the problems of easy occurrence of copper nodules, dispersibility and easy agglomeration restricting the development of high-quality copper foil, achieve good ionic stability, reduce copper effect of tumor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

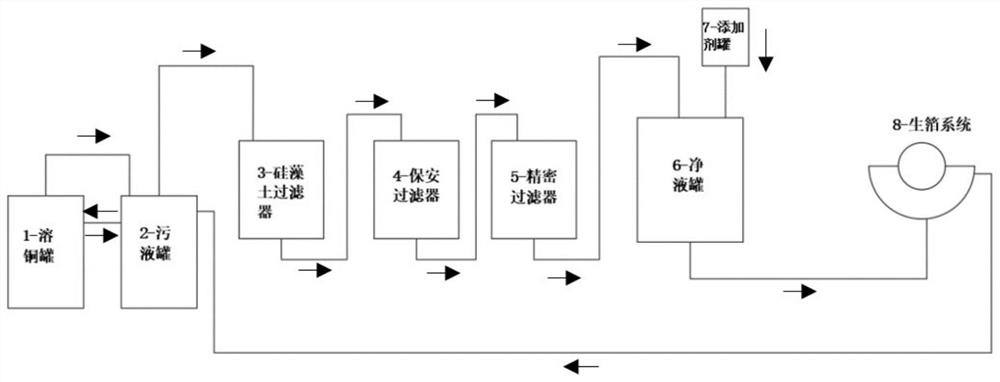

[0036] Follow the steps below to produce electrolytic copper foil:

[0037] S1 Preparation of copper sulfate solution: Add cathode copper of the model CU-CATH-1 to the copper-dissolving tank 1 containing sulfuric acid, and blow high-temperature air into the copper-dissolving tank 1 with a screw fan to prepare copper sulfate solution, copper sulfate solution Medium copper ion concentration is 90-100 g / L, sulfuric acid concentration is 115-120 g / L;

[0038] S2 Filtration of copper sulfate solution: transfer the copper sulfate solution in the copper dissolving tank 1 to the sewage tank 2, and then the copper sulfate solution passes through the diatomite filter 3, the security filter 4, and the precision filter 5 in sequence and then enters Clean liquid tank 6;

[0039] S3 adds hydroxyethyl cellulose to the copper sulfate solution: add hydroxyethyl cellulose to the net liquid tank 6 through the additive tank 7, the concentration of hydroxyethyl cellulose is 20mg / L, and the hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com