Acrylic resin emulsion for fingerprint-resistant paint and preparation method thereof

An acrylic resin and anti-fingerprint technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of sticking rolls and poor curing, poor high temperature resistance of coatings, etc., to achieve size matching, Good stability and uniform system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

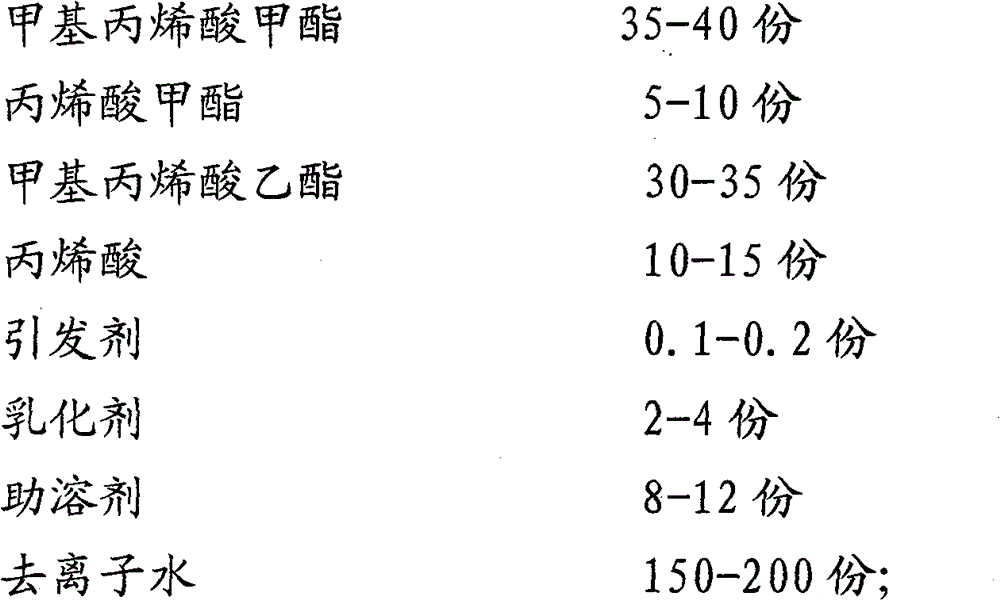

[0050] An acrylic resin emulsion for fingerprint-resistant coatings, calculated in parts by weight, composed of the following components through reaction polymerization:

[0051] 35 parts of methyl methacrylate;

[0052] 10 parts of methyl acrylate;

[0053] 30 parts of ethyl methacrylate;

[0054] 15 parts of acrylic acid;

[0055] 0.1 part of azobisisobutyronitrile;

[0056] 3 copies of OP-10;

[0057] 12 parts of ethylene glycol butyl ether;

[0058] 150 parts of deionized water.

[0059] The preparation method includes the following steps:

[0060] (1) Add OP-10, water, ethylene glycol butyl ether, and azobisisobutyronitrile into the reaction kettle, stir, and raise the temperature to 80°C;

[0061] (2) Mix methyl methacrylate, methyl acrylate, ethyl methacrylate and acrylic acid uniformly to form a monomer mixture, and add the monomer mixture dropwise to the reactor;

[0062] (3) 75℃, heat preservation for 1.5 hours;

[0063] (4) Filter out the material;

[0064] (5) Dilute with water to 30...

Embodiment 2

[0066] An acrylic resin emulsion for fingerprint-resistant coatings, calculated in parts by weight, composed of the following components through reaction polymerization:

[0067] 40 parts of methyl methacrylate;

[0068] 5 parts of methyl acrylate;

[0069] 35 parts of ethyl methacrylate;

[0070] 10 parts of acrylic acid;

[0071] 0.2 parts of azobisisobutyronitrile;

[0072] 1 copy of OP-10;

[0073] 1 part of sodium lauryl sulfate;

[0074] 8 parts of ethylene glycol butyl ether;

[0075] 200 parts of deionized water.

[0076] The preparation method includes the following steps:

[0077] (1) Add OP-10, sodium lauryl sulfate, water, ethylene glycol butyl ether, and azobisisobutyronitrile into the reaction kettle, stir, and heat to 70°C;

[0078] (2) Mix methyl methacrylate, methyl acrylate, ethyl methacrylate and acrylic acid uniformly to form a monomer mixture, and add the monomer mixture dropwise to the reactor;

[0079] (3) 80°C, heat preservation for 2 hours;

[0080] (4) Filter out the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com